Html"divp See detailed job requirements, duration, employer history, compensation amp; choose the best fit for youpdivdivdivimg src"http:gos. towa-online. atcub62ozvbuildbox-review. html"divp In order to do any major gameplay changes, add levels, enemies, etc, Buildbox is requiredpdivdivdivimg src"http:gos.

What is a vav air conditioning system/

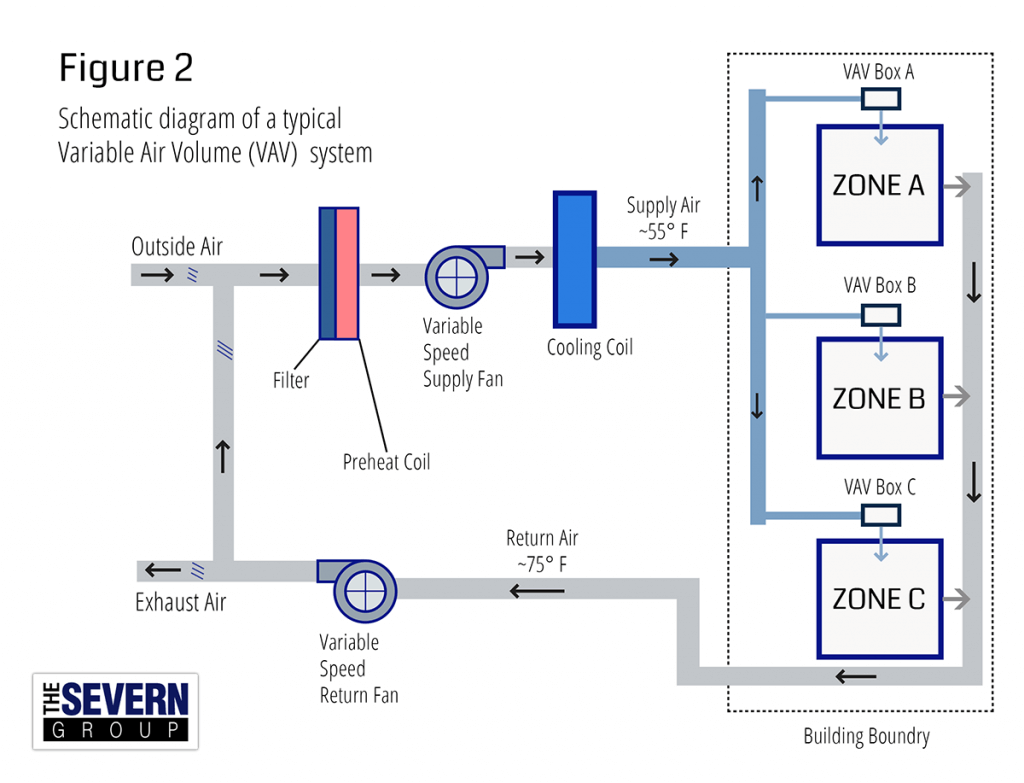

Variable Air Volume (VAV) systems are the most widely used types of HVAC air systems for medium- and large-sized commercial building projects (projects larger than 10,000 ft2) because VAV systems are flexible, energy efficient, and provide a comfortable indoor environment. VAV systems deliver variable supply airflow at a constant temperature (typically 55°F) through the primary air duct to multiple VAV terminal units, each of which serves a separate temperature zone. Each VAV terminal unit contains a motor-operated damper that modulates the primary airflow to the zone, an inlet airflow sensor, and, in some instances, a heating coil and a small recirculating air fan.

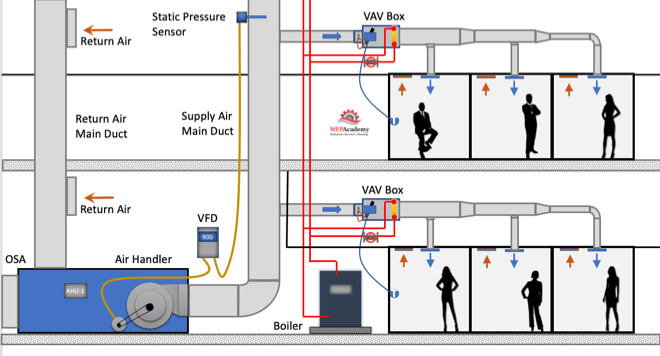

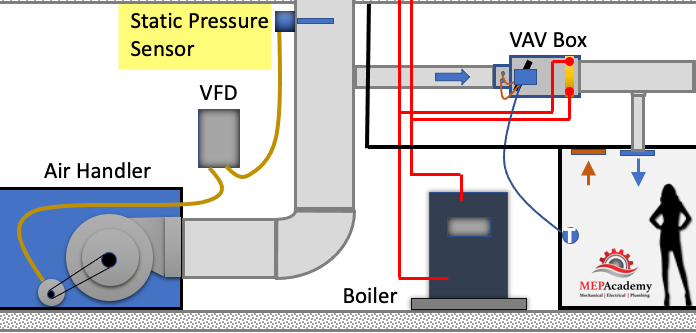

The supply airflow from the VAV air handling unit is normally modulamd to maintain a constant static pressure within the primary air duct system. This is measured by a duct static pressure sensor, which is typically located two-thirds the way down the primary air duct system. The modulation of the supply airflow traclcs with the needs of the VAV termirutl units; that is, as more primary air dampers in the VAV terminal units open to supply more air to the zones, the static pressure in the primary air duct system decreases and the fan speed in the VAV air handling unit increases to increase the supply airflow delivered by the VAV air handling unit to restore the static pressure in the duct system. Conversely, as the primary air dampers close, the primary air duct static pressure increases and the fan speed in the VAV air handling unit decreases to decrease the supply airflow delivered by the VAV air handling unit to compensate.

The air handling unit for a VAV system is the same as would be required for a CAV system with the exception that there is a means of modulating the supply airflow delivered by the unit. The most common what is a vav air conditioning system of modulating the supply airflow of the unit is by controlling the frequency of the signal sent to the supply fan motor through a variable frequency drive (VFD).

Constant Air Volume (CAV) Systems

The speed of an alternating current (ac) motor is directly proportional to the frequency of the input signal to the motor. Therefore, as the frequency of the VFD output signal to the motor is reduced, motor speed is reduced, and supply airflow is also reduced. The converse is true as the frequency of the VFD output signal to the motor is increased. The maximum recommended frequency of the VFD output signal is that of the VFD line input frequency, or 60 Hz. The supply fan motor will operate at full speed when it receives a VFD output signal of 60 Hz. VFDs can deliver frequencies higher than 60 Hz, but this causes the fan motor to operate above its rated running load amps [i.e., the motor operates in its service factor range (typically between 100 and 115% of the rated running load amps), which is not recommended].

Care should be taken when designing VAV systems that utilize DX refrigerant coils for cooling. Unless the refrigeration system is equipped with adequate capability to unload the refrigeration system capacity, freeze-up of the DX refrigerant cooling coil could occur under low airflow conditions. Unloading of the refrigeration system, adequate control of the discharge air temperature, and incorporation of a VFD into the unit cabinet are all issues that HVAC equipment manufacturers have recently resolved for DX equipment having capacities less than 25 tons. HVAC equipment manufacturers now offer VAV operation for air systems that utilize DX refrigerant cooling coils in capacities as low as 5 tons.

The most common use of a VAV system is in serving multiple temperature zones. Therefore, we will discuss multiple-zone VAV systems first and then discuss the use of a VAV system for a single-zone application.

Multiple-Zone

VAV Terminal Units

Variable primary airflow is delivered to the zones through the modulation of the primary air damper in the VAV terminal units. As the zone temperature decreases, the primary air damper is modulated closed to supply less (55°F) primary air to the zone. Once the primary air damper reaches its predetermined minimum position (usually about 25% of maximum airflow), upon a further drop in the zone temperature, VAV terminal units that have heating capabilities will position the primary air damper to the heating airflow and modulate the output of the heating coil to maintain the heating setpoint of the zone temperature sensor. Fan-powered VAV terminal units are also equipped with a small fan that recirculates air (normally from the ceiling return air plenum) through the heating coil of the VAV terminal unit.

Figure 1 is a schematic diagram of a VAV system serving multiple VAV terminal units.

Dual-Duct

Dual-duct VAV air systems are about as uncommon as dual-duct CAV air systems. The most likely time an HVAC system designer would encounter a dual-duct VAV air system would be in the case of a system that was originally designed as a dualduct CAV system but was what is a vav air conditioning system renovated to function as a VAV system. The HVAC system designer may also have the task of designing the modifications to a dual-duct CAV system to convert it to a dual-duct VAV system.

Dual-duct VAV systems function much the same way as dual-duct CAV systems except the supply airflow to the zones is variable, not constant. The supply fan in the dual-duct air handling unit has to be equipped with a means to modulate its airflow in response to static pressure in both the main hot and cold ducts. The what is a vav air conditioning system efficiency of a dual-duct VAV system would be about the same as that of a conventional VAV system utilizing VAV terminal units.

Care should be taken in converting a dual-duct CAV system to a VAV system to ensure that the zones do not require constant supply airflow to serve as makeup for constant exhaust airflow.

Single-Zone

Operation of a single-zone VAV system is similar to the operation of a VAV system serving multiple zones, except there are no VAV terminal units and the supply airflow is modulated to maintain the cooling setpoint of the (single) zone temperature sensor rather than to maintain a constant primary air duct static pressure. The supply air tempemture is maintained at 55°F as long as the zone temperature sensor is calling for cooling.

Once the zone temperature drops below the cooling setpoint (typically 75°F), the air handling unit will operate in the heating mode: cooling will be disabled, the supply fan will operate at the predetermined heating airflow, and the output of the heating coil within the unit will be modulated as required to maintain the heating setpoint what is a vav air conditioning system the zone temperature sensor (typically 70°F).

Once the zone temperature rises above the cooling setpoint, the air handling unit will operate in the cooling mode: heating will be disabled, the output of the cooling coil will be modulated as required to maintain the supply air temperature at 55°F, and the supply airflow will be modulated to maintain the cooling setpoint of the zone temperature sensor.

The advantage of a single-zone VAV over a single-zone CAV system is that during cooling operation, the supply air temperature will remain constant at approximately 55°F. This consistently cool supply air temperature will result in a lower space relative humidity than the same area served by a CAV system where the supply air temperature can vary anywhere between 55°F (full cooling load) and 75°F (no cooling load). The higher space relative humidity resulting from the use of a CAV system is exacerbated by outdoor air ventilation in moist climate zones and by a high density of occupants in the areas served by the unit.

Due to recent advances in technology, single-zone VAV systems that utilize DX refrigerant cooling coils can serve areas with a cooling load as low as 5 tons.

HVAC Design Sourcebook - W. Larsen Angel, P.E., LEED AP, is a principal in the MEP consulting engineering firm Green Building Energy Engineers. He has worked in the MEP consulting engineering industry for more than 30 years. Mr. Angel has contributed to the development of design standards and continues to find new ways to streamline the HVAC system design process.How a Variable Air Volume VAV System Works

Variable Air Volume (VAV) is the most used HVAC system in commercial buildings. In this article we’ll discuss the Variable Air Volume system and single duct VAV boxes with reheat coils. The Air Handler varies the amount of air flow (CFM) at the overall system level based on the demand required by the zone level VAV boxes, which vary air flow based on their local demand.

To watch the Video of this presentation, scroll to the bottom.

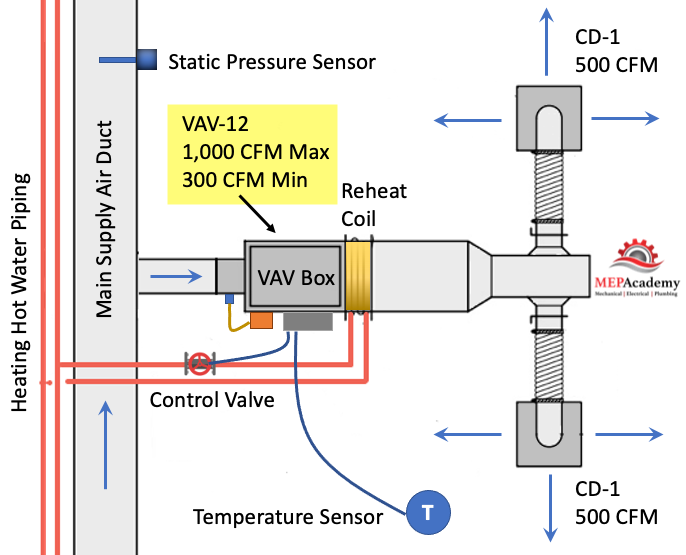

The VAV box regulates the flow (CFM) to a zone in relationship to the demand of the temperature sensor in the space.

Variable air volume is more energy efficient than constant volume flow because of the reduction in fan motor energy due to reducing fan speed (RPM) at partial load. As the cooling or heating demand is reduced because of a mild temperature day, the VAV Air Handler system can reduce the amount of air flow (CFM) by reducing the fan speed.

The air handler will deliver a constant temperature of 55ºF (13 ºC) supply air to the VAV boxes. While the supply air temperature stays constant the volume (CFM) of air will vary based on the total demand of all the zones on the system. There are several control strategies to adjust the speed of the fan which we’ll discuss below.

As the VAV boxes open or close due to demand called for by the temperature sensor in the space, the pressure in the main supply air duct will either increase or decrease. This pressure change is picked up by a static pressure sensor in the main supply air duct.

As the pressure increases in the main supply duct because the VAV boxes are closing their dampers and are adjusting their dampers towards the minimum open setting, the air handler supply fan VFD slows down the fan. The opposite will happen due to the VAV boxes opening because of increased demand and the dampers are opening, in this case the VFD will cause the supply fan to speed up when the pressure in the main supply air duct drops.

The VFD will try to maintain the speed (RPM) of the fan so that the static pressure in the duct at the location of the static pressure sensor maintains some minimum set-point, such as 1.25” sp. The what is a vav air conditioning system pressure sensor sends a signal to the VFD and the speed of the fan is adjusted according to the set-point required.

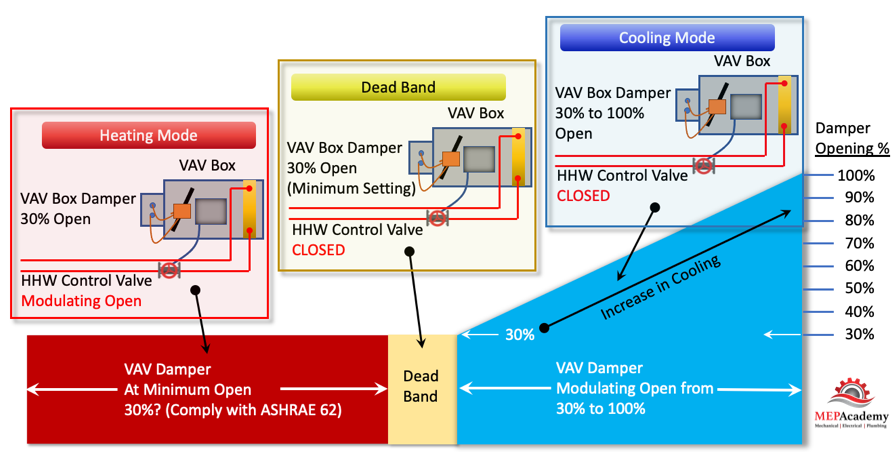

The VAV box at the zone level will operate in one of three modes: Cooling Mode that varies the flow rate (CFM) to meet a temperature setpoint; a Dead-Band Mode where the temperature setpoint is satisfied and the box is at minimum flow (CFM); and a Reheat Mode for when the space requires heat.

As you can see in the diagram above the VAV Damper goes from a minimum of 30% open, whatever the minimum required to meet ASHRAE 62, all the way to the damper being 100% open.

There are basically three modes in this control strategy. Mode #1 Is the Cooling Mode where the heating hot water control valve is closed and the VAV damper modulates what is a vav air conditioning system 30% to 100% open in order to satisfy the temperature sensor. Next is Mode #2 Dead Band Mode is when there is no need for cooling or heating, so the damper stays in its minimum position to meet the ventilation requirements of ASHRAE 62. And Mode #3 is the Heating Mode where the VAV box damper remains in the minimum position and the heating hydronic vav water valves modulates open to satisfy the heating requirements of the space.

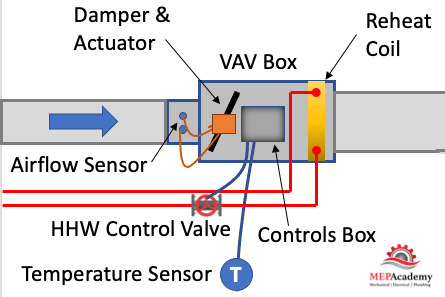

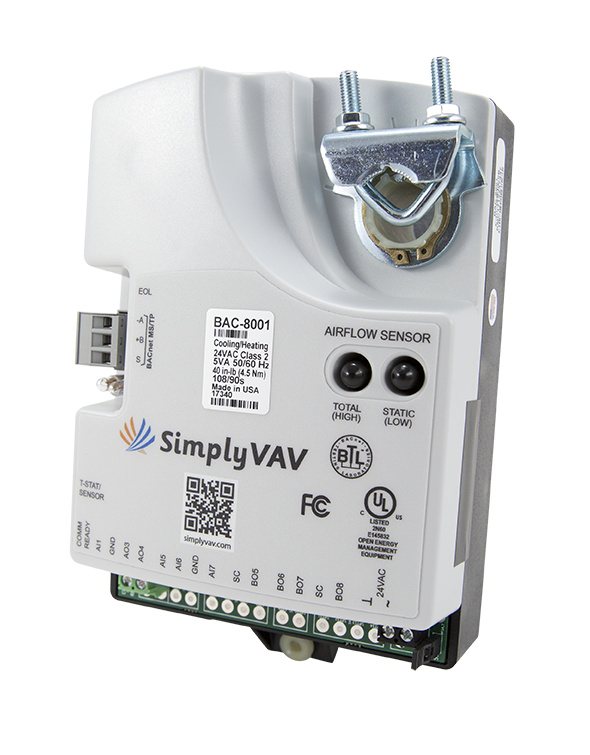

The VAV box has a damper at its inlet moved by an actuator that is controlled by the controller that takes its command from a temperature sensor. The process is very simple. When the temperature sensor in the space calls for cooling it sends a command to the VAV box controller which then adjust hydronic vav supply air flow rate (CFM). The adjustment is done by an actuator rotating the VAV box inlet damper either open or closed in increments.

- Airflow Sensor – is used to adjust the damper position by measuring the air flow at the inlet of the box. The airflow sensor measures total pressure and static pressure to determine the Velocity Pressure which helps the controller determine the CFM through the inlet of the VAV box. Velocity Pressure what is a vav air conditioning system Total Pressure – Static Pressure.

- Actuator – Based on the airflow the actuator will power the rotation of the damper to meet the space demand.

- Damper – adjust airflow (CFM) based on the temperature sensor and airflow sensor input.

- Reheat Coil – Depending on the zone, there may be a reheat coil that provides heating from heating hot water, steam or electric. The use of electric is limited in some jurisdiction due to energy codes.

- VAV Box Controller – Taking input from the temperature sensor and the airflow sensor the controller will send and output signal to the damper or heating hot water valve to modulate open or closed. Controls can be pneumatic, electronic, or direct digital control (DDC). Pneumatic is an older form of control and is being replaced by the more energy efficient DDC system.

- Other components used on various other versions of the VAV box, such as fan powered boxes would include fans and filters.

Before we get any deeper into this subject we need to cover the basics of zoning. Zoning is how the Engineering divides up the building into separate VAV zones, with each zone getting its own VAV box. To keep cost down its best to limit the amount of VAV boxes used, as each box adds additional cost for material, labor, controls and electrical.

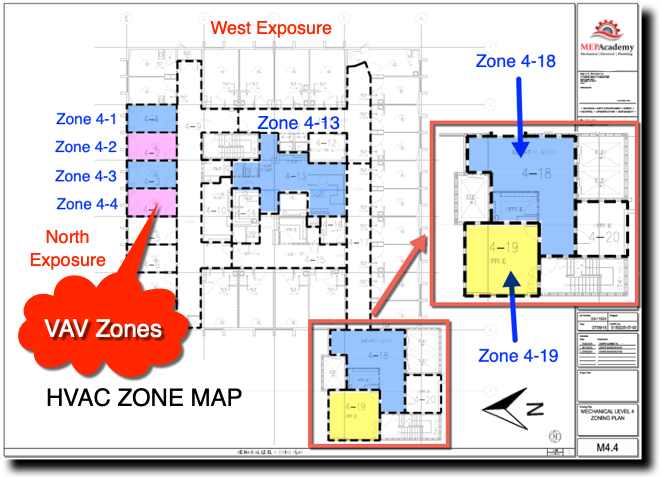

After a heating and cooling load is completed on a building, the spaces will be divided up into zones. Each individual zone will have similar load profiles and be served by the same VAV box. A typical individual zone maybe offices that share a southern glass exposure or interior spaces. Look for a Zone drawing in any set of mechanical plans that has a large area broken down into zones. (See example of a Zone Map Drawing below)

The idea of zoning is to breakdown large areas of a building into smaller zones with similar load profiles. When a zone on the south facing portion of a building is calling for maximum cooling, the north facing zones may be in minimum cooling or heating mode. Zoning allows different spaces the ability to provide cooling or heating and vary the flow (CFM) depending on the demand of that zone’s temperature sensor.

All the zones on a floor of a high-rise maybe fed from the same air handler, but each zone can adjust its CFM according to their specific needs. Depending on the size of the floor plate, there maybe two Air Handlers per floor, or for smaller floors the Air Handler may feed more than one floor. The Vava moov 28 wireless headphones reviews Handler can be located on the floor within a mechanical room or located on the roof.

The supply air main is considered the high side of the system. The high side being the main supply duct from the air handler to the inlet of each VAV box. The main is considered upstream of the VAV box, while downstream of the box is considered the low-side supply.

The air handler will provide 55 F degree (13 Celsius) supply air to the VAV box. The Variable Air Volume VAV box will then determine how much air (CFM) to pass through to the space based on the demand of the space. The air handler is sized to meet the maximum block load of the area it serves. The block load is basically the peak heating or cooling load of all the zones combined. It is not the total CFM of all the peaks of each zone, but the total based on the worst month, day and time of year where the total block is at its maximum load.

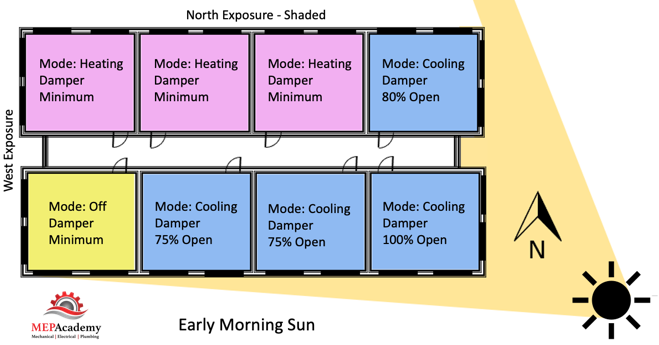

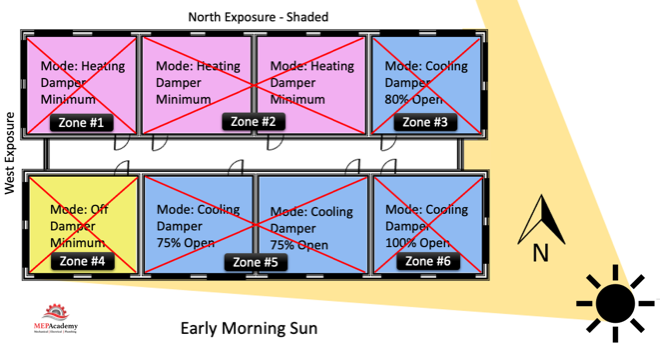

Each zone above is reacting differently to the early morning sun. Some zones are in cooling mode with their dampers at different percentages of being open, while other zones are in heating and one zone is off and receiving minimum air for ventilation. This is a very basic diagram of how zones may differ and why it’s important to consider how spaces are grouped together, as each space may have a different solar exposure and cooling load profile. As the sun travels across the sky the zone dampers will open or close depending on their need for heating or cooling.

Corner spaces are often difficult to include with other spaces because they have two exposures. It’s like living on the corner in your block, you have two streets. Looking at the image we can see that there are two cooling zones between corner spaces that are on the south exposure that could be grouped into one zone, Zone #5 below. The same is true for the two zones between corner spaces on the North exposures, Zone #2. If you had interior zones they would be separated from any exterior zone because interior zones are often exclusively in cooling mode due to internal heat gains and the lack of heat loss from any exterior surfaces.

Cooling Mode

During cooling mode, the Variable Air Volume VAV box will modulate between a minimum CFM setpoint and the calculated design maximum cooling CFM setpoint based on the zones peak cooling demand. When the hot summer arrives and the sun shines through windows and conducts heat through the walls and roofs, the need for cooling will be sensed by the temperature sensors in the space which will call for the VAV box to open its damper and let more cold air into the room. Or, if you’re in a room located within the interior of the building, like a conference room, then the heat from the people, lights and plug loads will cause the temperature sensor to initiate an opening of the VAV box damper for more cold air.

For exterior zones and in certain cases interior zones there will be a reheat coil or an electric heater attached to the VAV box The reheat coil can be served by heating hot water, steam or electric. When in heating mode, the flow (CFM) through the box will be at a minimum setpoint to avoid wasting energy. Remember that the air handler is sending the VAV box 55 F degree (13 Celsius) supply air which was most likely cooled by chilled water from a chiller.

This primary what is a vav air conditioning system air will also bring a percentage of mandatory ventilation air (Outside Air). In some systems the supply air temperature could be increased to a temperature that is just cool enough to cool the most-demanding zone with its VAV box set to maximum flow, thereby saving additional energy.

The heating hot water valve will modulate open providing a range of heating hot water flow (GPM) to meet the heating load. The minimum CFM setpoint can be somewhere between 30% and 50% of the maximum cooling setpoint. Minimums are set by some code jurisdiction so what is a vav air conditioning system the minimum ventilation rate is always achieved. In California see Title-24 Sec 120.1 Requirements for Ventilation and Indoor Air Quality. See Ventilation section next.

Using electric heat is not approved in various jurisdictions. Check your local code for approved sources for the heating requirements.

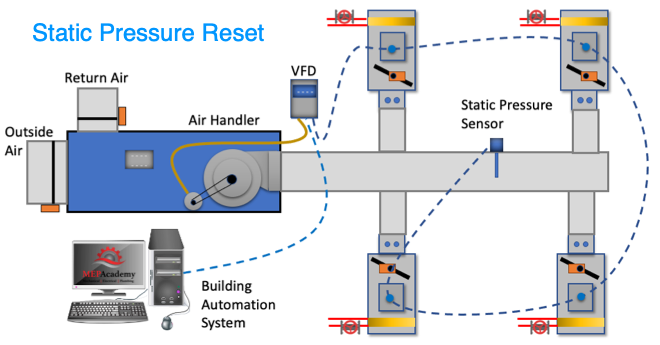

We’ll mention two control strategies for optimizing energy efficiency using a VAV system. These are the 1) Constant Static Pressure Control Method, and 2) Static Pressure Reset. (Required if there is a DDC system to the zone level)

When the VAV boxes are connected to a building automation system that monitors the function and status of the boxes there are various options for control. This is based on using a DDC system.

#1 Constant Static Pressure Control Method

Usually, a pressure sensor is installed 2/3 rds. of the way down the main supply air duct. When VAV boxes start closing their dampers because they need less cooling an increase in pressure will occur. When the static pressure in the supply duct increases due to the VAV boxes closing their inlet dampers the static pressure in the main supply air duct increases.

The pressure sensor what is a vav air conditioning system the duct will send a signal to the Variable Frequency Drive (VFD) causing the supply and return fans to slow down or reduce its RPM. If the pressure in the duct decreases because the VAV boxes are opening due to the need for additional cooling, the pressure sensor will send a signal to increase the fan speed (RPM).

The pressure sensor is set to maintain a constant pressure in the main supply duct which often causes excess static pressure to be provided when compared to option two below. The reduction in the fan speed provides energy savings.

#2 Static Pressure Reset

The use of this strategy is required by Title-24 (California) and ASHRAE 90.1 for system that have DDC to the zone level. The static pressure setting in the main supply duct is reduced to a point where one VAV box damper is nearly full open. This is the zone that requires the most pressure. This would require that the VAV box actuators can report their damper position, best performed with an analog output. Look for Trim and Respond logic for more information.

These options provide a good opportunity to save energy by reducing the fan speed and possibly increasing the supply air temperature in small increments with continuous polling. If the supply temperature can be reset above the economizer set point, then the compressors can stage off and the cooling can be provided by modulating the return air and outside air dampers to deliver the desired supply air temperature.

Using a DDC control system with VAV boxes that have a flow station and temperature sensor at the supply air discharge the system can determine the amount of reheat.

Q = CFM x 1.08 x Delta-T

Q = Btu/Hr

1.08 = A constant based on standard air conditions

Delta-T = (Discharge Air Temperature – Primary Supply Air Temperature)

The building automation system can track and trend over long periods of time the following: Damper position, static pressure, reheat valve position, airflow rate (CFM), supply air temperature, zone temperature and occupancy status.

There are other types of VAV boxes not discussed here such as: Fan Powered VAV Box, VAV Mixing Box (Dual Duct Systems), CAV (Constant Air Volume).

Ventilation air (Outside Air) is required for all occupied spaces according to ASHRAE standard 62.1. When using VAV boxes the minimum volume setting of the box needs to ensure the larger of the following:

1. 30 percent of the peak supply volume;

2. Either 0.4 cfm/sf or (0.002 m3/s per m2) of conditioned zone area; or

3. Minimum CFM (m3/s) to satisfy ASHRAE Standard 62 ventilation requirements. VAV terminal units must never be shut down to zero when vav motors system is operating. Outside air requirements shall be maintained in accordance with the Multiple Spaces Method, Equation 6-1 of ASHRAE Standard 62 at all supply air flow conditions.

The use of Variable Air Volume (VAV) has been shown to save energy when combined with a supply fan VFD’s. As the demand in the spaces fluctuate the VAV box dampers open or close proportionately and the air handler fans respond through various control strategies. Variable air volume systems save more energy than a constant volume system.

Constant Air Volume and Variable Air Volume: Difference

In the modern world, the building sector demands comfort and energy efficiency. The design of heating, ventilation and air conditioning (HVAC) systems has a significant impact on both, and working with a qualified engineering firm has a positive impact on the final outcome.

A key decision in HVAC design is selecting an adequate air-handling configuration: constant air volume (CAV) or variable air volume (VAV). Each option has advantages and disadvantages, and using the right configuration enhances comfort and efficiency.

This article provides an overview of CAV and VAC systems, describing the principles and calculations used by HVAC what is a vav air conditioning system during the design process.

Get an HVAC design that meet the needs of your building.

Constant Air Volume Systems

CAV systems keep a constant airflow, as their name implies, and the desired indoor conditions are reached by adjusting the air supply temperature. For example, what is a vav air conditioning system a building requires a higher cooling output on a hot summer day, the CAV system delivers colder air. In chilled water systems, the cooling effect depends on the cold water flow delivered to the fan coil unit. In turn, the water flow controller operates based on the thermostat settings.

CAV systems can be of single-zone or multi-zone types, although they are better suited for single-zone applications where the load experiences minimal change over time. Some examples are auditoriums, theaters and museums. Multi-zone CAV systems require duct heating to deliver different air temperatures for individual zones, which reduces their energy efficiency.

The operation of a multi-zone CAV system can be described best with an example. Consider the following design conditions:

An indoor air-handling unit (AHU) serves three zones (A, B and C).

Each of what is a vav air conditioning system three zones has a dedicated thermostat.

The AHU gets cold water from a chiller with a cooling tower.

Air duct heaters are what is a vav air conditioning system to the main branches serving individual zones.

The thermostats are set at 55°F (A), 68°F (B) and 72°F (C).

The AHU delivers cool air at 55°F.

Once the supply air enters the duct system, it can only be heated and not cooled. Therefore, it must be supplied at the lowest of the three temperatures required - 55°F for zone A in this case. After zone A is served, the air flow can be heated to the temperatures required for other zones: 68°F for zone B and 72°F for zone C.

Although the operating principle is simple, it has an efficiency limitation. Part of the cooling output is wasted when air is reheated for zones B and What is a vav air conditioning system, and the duct heaters themselves also consume energy.

Variable Air Volume Systems

As you might guess, VAV systems keep the air temperature constant, and instead they adjust airflow depending on the load. VAV systems can have single-zone, multi-zone or dual duct configurations. Just like CAV is the preferred option in single-zone systems, VAV is recommended for multi-zone systems.

Dual duct VAV systems have separate ducts for hot and cold air, and each zone has a plenum where their airflow is mixed. The ratio of hot and cold air depends on the desired temperature for each particular zone. This HVAC configuration is the most expensive in terms of installation, operation and maintenance.

Multi-zone systems have VAV boxes that control the what is a vav air conditioning system supplied to individual zones. Unlike CAV, the cold water flow supplied to the fan coil unit is kept constant. VAV systems achieve their full potential in applications where there a multiple zones with variable load. Some examples are malls, hotels and office buildings.

VAV boxes have a role similar to the duct heaters used in a CAV system. Instead of reheating air according to the needs of each individual zone, the airflow is controlled while keeping temperature constant.

Basic Calculations in CAV and VAV Design

The HVAC design process involves complex calculations and energy modeling. However, the equations that describe system operations are simple. This section describes how temperature and airflow are adjusted according to load.

The starting point is the sensible heat gain equation, which is fundamental in HVAC systems:

Where:

- Q = Load of the room or zone being served (BTU / hour)

- CFM = Airflow in cubic feet per minute

- ΔT vav 1875 Difference between the room temperature and what is a vav air conditioning system supply air temperature

Example 1 - VAV System

Let’s assume that a room has a load (Q) of 10,000 BTU/h, with an indoor temperature of 75°F and a supply air temperature of 55°F. In this case, the difference is 20°F. To calculate the required airflow, the sensible heat equation can what is a vav air conditioning system rearranged:

- Q = 1.08 x CFM x ΔT

- CFM = Q ÷ (1.08 x ΔT)

- CFM = 10,000 BTU/h ÷ (1.08 x 20°F) = 463 cfm

In this case, the VAV system would have to adjust airflow to 463 cfm for the corresponding zone. Let’s observe the effect when the load is increased to 12,000 BTU/h.

- CFM = 12,000 BTU/h ÷ (1.08 x 20°F) = 555 cfm

The temperature difference of 20°F is kept constant under a load of 12,000 BTU/h, while increasing airflow to 555 cfm.

Example 2 - CAV System

In this case, the cooling load and room temperature are the same used in the example above: 10,000 BTU/h and 75°F. However, the airflow is fixed at 500 cfm and the air supply temperature is adjusted. The sensible heat equation would be rearranged as follows:

- ΔT = Q ÷ (1.08 x CFM)

- ΔT = 10,000 BTU/h ÷ (1.08 x 500 cfm)

- ΔT = 18.52°F

The air supply must be 18.52°F below room temperature, which is equivalent to 56.48°F. Repeating the calculation for 12,000 BTU/h, the following result is achieved:

- ΔT = Q ÷ (1.08 x CFM)

- ΔT = 12,000 BTU/h ÷ (1.08 x 500 cfm)

- ΔT = 22.22°F

In this case, the required air supply temperature is 52.78°F.

Conclusion

HVAC engineers can choose between CAV and VAV systems depending on the application. While a CAV system uses variable air temperature and constant airflow, a VAV system keeps constant temperature and variable airflow. Vava moov 28 wireless headphones reviews systems are better suited for single-zone applications where the load experiences little change, while VAV systems are the best option for multi-zone applications with a constantly changing load.

Make sure your mechanical installations are code compliant and energy efficient, while getting a 50% faster turnaround. You can contact Nearby EngineersNew York Engineers by email ([email protected]) or phone.

What is Variable Air Volume in an HVAC system?

In a nutshell, Variable Air Volume (VAV) is an HVAC system that has a stable supply-air temperature and varies the air flow rate to meet the temperature requirements. Compared to constant air volume systems, these VAV systems conserve energy through lower fan speeds during times of lower temperature control demand. Most new commercial buildings have VAV systems. VAVs may be bypass type or pressure dependent. Pressure-dependent type VAVs save energy while both types help in maintaining the temperature of the zone that it feeds. Abbreviated VAV.

There are several what is a vav air conditioning system benefits to using a Variable Air Volume system in your HVAC needs:

- Energy efficiency – as mentioned earlier, one of the key advantages of a VAV system is that it can help save energy due to its ability to lower fan speeds during times of lower temperature control demand.

- Flexibility – VAV systems are also more flexible compared to other types of HVAC systems, making it easier to adapt to changes in temperature requirements.

- Improved indoor air quality – since VAV systems can better control the flow of air, this also results in improved indoor air quality overall.

- Enhanced comfort levels – with a VAV system in place, you can enjoy enhanced comfort levels as the system is designed to maintain a stable supply-air temperature.

What does a Variable Air Volume do?

The main purpose of a VAV system is to provide conditioned air at the right temperature and humidity while also conserving energy.

What is a Variable Air Volume unit?

A Vava moov 28 wireless headphones reviews unit is a self-contained air handling unit that is typically used in smaller applications. VAV units what is a vav air conditioning system consist of a blower, cooling coil, heating coil, and filter. These units are designed to provide conditioned air at the right temperature and humidity while also conserving energy. In order to do this, VAV units vary the volume of air that is being delivered based on the specific needs of the space. When the space requires less cooling or heating, the system will automatically adjust the airflow accordingly.

What is the difference between constant air volume and Variable Air Volume control?

Constant air volume (CAV) systems deliver a constant volume of air regardless of the space’s heating or cooling needs. This can result in wasted energy as the system is not able to adjust the airflow based on the specific needs of the space. On the other hand, Variable Air Volume (VAV) systems vary the volume of air that is being delivered based on the specific needs of the space. When the space requires less cooling or heating, the system will automatically adjust the airflow accordingly.

Which is better CAV or VAV?

There is no definitive answer as to which system is better as it depends on the specific needs of the space. However, in general, VAV systems are more energy-efficient as they are able to adjust the airflow based on the specific needs of the space. This results in less wasted energy and improved indoor air quality and comfort levels.

VAV valve operation

VAV systems use a variety of methods to control the volume of air that is being delivered to the space. One of the most common methods is to use a VAV valve. VAV valves are typically controlled by a thermostat or pressure sensor. When the space’s heating or cooling needs to change, the thermostat or pressure sensor will send a signal to the VAV valve to adjust the airflow accordingly. This not only helps save energy but also results in improved indoor air quality and enhanced comfort levels.

Related Links

Variable air volume

The Case for High-Performance Variable-Air-Volume (VAV) Systems

VAV Units – Variable Air Volume Systems

CAV vs VAV HVAC Systems

How VAV Boxes Work

Variable Air Volume Systems

Variable Air Volume Systems – Better Buildings Partnership

Related Videos

Variable air volume

Heating or air-conditioning system

Variable air volume (VAV) is a type of heating, ventilating, and/or air-conditioning (HVAC) system. Unlike constant air volume (CAV) systems, which supply a constant airflow at a variable temperature, VAV systems vary the airflow at a constant or varying temperature.[1][2] The advantages of VAV systems over constant-volume systems include more precise temperature control, reduced compressor wear, lower energy consumption by system fans, less fan noise, and additional passive dehumidification.[3]

Box technology[edit]

The most simple form of a VAV box is the single duct terminal configuration, which is connected to a single supply air duct that delivers treated air from an air-handling unit (AHU) to the space the box is serving.[2] This configuration can deliver air at variable temperatures or air volumes to meet the heating and cooling loads as well as the ventilation rates required by the space.[2]

Most commonly, VAV boxes are pressure independent, meaning the VAV box uses controls to deliver a constant flow rate regardless of variations in system pressures experienced at the VAV inlet.[2] This is accomplished by an airflow sensor that is placed at the VAV inlet which opens or closes the damper within the VAV box to adjust the airflow.[2] The difference between a CAV and VAV box is that a Goblins vave box can be programmed to modulate between different flowrate setpoints depending on the conditions of the space. The VAV box is programmed to operate between a minimum and maximum airflow setpoint and can modulate the flow of air depending on occupancy, temperature, or other control parameters.[4] A CAV box can only operate between a constant, maximum value, or an “off” state.[5] This difference means the VAV box can provide tighter space temperature control while using much less energy. Another reason why VAV boxes save more energy is that they are coupled with variable-speed drives on fans, so the fans can ramp down when the VAV boxes are experiencing part load conditions.[6][7]

It is common for VAV boxes to include a form of reheat, either electric or hydronic heating coils.[4] While electric coils operate on the principle of electric resistance heating, whereby electrical energy is converted to heat via electric resistance, hydronic heating uses hot water to transfer heat from the coil to the air. The addition of reheat coils allows the box to adjust the supply air temperature to meet the heating loads in the space while delivering the required ventilation rates.[2] In some applications it is possible for the space to require such high air-change rates it causes a risk of over-cooling.[5] In this scenario, the reheat coils could increase the air temperature to maintain the temperature setpoint in the space.[2] This scenario tends to happen during cooling seasons in buildings which have perimeter and interior zones. The perimeter zones, with more sun exposure, require a lower supply air temperature from the air-handling unit than the interior zones, which have less sun exposure and tend to stay hebrew meaning of vav than the perimeter zones when left un-conditioned. With the same supply air temperature being delivered to both zones, the reheat coils must heat the air for the interior zone to avoid over-cooling.[8]

Multiple-zone systems[edit]

The air blower's flow rate is variable. For a single VAV air handler that serves multiple thermal zones, the flow rate to each zone must be varied as well.

A VAV terminal unit,[9] often called a VAV box, is the zone-level flow control device. It is basically a calibrated air damper with an automatic actuator. The VAV terminal unit is connected to either a local or a central control system. Historically, pneumatic control was commonplace, but electronic direct digital control systems are popular especially for mid- to large-size applications. Hybrid control, for example having pneumatic actuators with digital data collection, is popular as well.[10]

A common commercial application is shown in the diagram. This VAV system consists of a VAV box, ductwork, and four air terminals.

Fan control for a pressure-independent system[edit]

Control of the system's fan capacity is critical in VAV systems. Without proper and rapid flow rate control, the system's ductwork, or its sealing, can easily be damaged by overpressurization. In the cooling mode of operation, as the temperature in the space is satisfied, a VAV box closes to limit the flow of cool air into the space. As the temperature increases in the space, the box opens to bring the temperature back down. The fan maintains a constant static pressure in the discharge duct regardless of the position of the VAV box. Therefore, as the box closes, the fan slows down or restricts the amount what is a vav air conditioning system air going into the supply duct. As the box opens, the fan speeds what is a vav air conditioning system and allows more air flow into the duct, maintaining a constant static pressure.[11]

One of the challenges for VAV systems is providing adequate temperature control for multiple zones with different environmental conditions, such as an office on the glass perimeter of a building vs. an interior office down the hall. Dual duct systems provide cool air in one duct and warm air in a second duct to provide an appropriate temperature of mixed supply air for any zone. An extra duct, however, is cumbersome and expensive. Reheating the air from a single duct, using electric or hot water heating, is often a more cost-effective solution.[12]

Reheat applications - Controls and energy what is a vav air conditioning system VAV reheat systems use minimum airflow rates of 30% to 50% the design airflow. These airflow minimums are selected to avoid the risk of under-ventilation and thermal comfort issues. However, published research supporting the efficacy of this approach is scarce. Systems operating at lower minimum airflow ranges (10% to 20% of design airflow) stand to use less fan and reheat coil energy relative to a traditional system, and recent research has shown that thermal comfort and adequate ventilation can the vava boom be attained at these lower minimums.[13]

VAV reheat systems using the higher minimum airflow typically employ a conventional "single maximum" control sequence. Under this control sequence, a single cooling maximum airflow setpoint is selected for design what is a vav air conditioning system conditions. The cooling airflow is gradually lowered to the minimum airflow setpoint, where it remains as the space temperature lowers beyond the cooling temperature setpoint. When the heating setpoint is reached, the electric or hydronic heating coil is activated and gradually provides more heat until the maximum heating capacity is reached at the design heating temperature.[14]

Research has shown that using a different, "dual maximum" control sequence can save substantial amounts of energy relative to the conventional "single maximum" control sequence. This is accomplished due to the "dual maximum" sequence’s use of lower minimum airflow rates.[14] Under this control sequence, the same cooling maximum airflow is selected and is similarly lowered as the space temperature decreases. By the time the space temperature drops to the cooling temperature setpoint, the airflow reaches a lower minimum value than that used in the "single maximum" sequence (10% - 20% vs. 30% - 50% of maximum cooling airflow). When the space temperature reaches the heating temperature setpoint, the heating coil is activated and increases its electrical power (for electric coils) or hot water valve position (for hydronic coils) while the airflow remains at the minimum setpoint. When the heating coil reaches its maximum heating capacity, upon a further drop in space temperature, the airflow is increased until it reaches a maximum heating airflow setpoint (typically about 50% of the maximum cooling airflow).[5]

References[edit]

- ^Muresan, Flori. "Ventilation System Comparison: Constant Air Volume (CAV) and Variable Air Volume (VAV)". www.ny-engineers.com. Retrieved 2022-11-10.

- ^ abcdefg"Variable Air Volume (VAV) Systems Operations and Maintenance". Pacific Northwest National Laboratory.

- ^Lu, Daniel B.; Warsinger, David M. (2020). "Energy savings of retrofitting residential buildings with variable air volume systems across different climates". Journal of Building Engineering. Elsevier BV. 30: 101223. doi:10.1016/j.jobe.2020.101223. ISSN 2352-7102. S2CID 216163990.

- ^ abKreider, Jan F. (2010). Heating and cooling of buildings : design for efficiency. Peter Curtiss, Ari Rabl (Rev. 2nd ed.). Boca Raton: CRC Press/Taylor & Francis. ISBN . OCLC 455835575.

- ^ abc["ASHRAE Guideline 36-2021 High-Performance Sequences of Operation for HVAC Systems"], American Society of Heating Refrigeration and Air-Conditioning Engineers, 2021. Retrieved on 14 November 2022.

- ^"Reliance Electric GV3000 Drive 40V4160

CAV vs VAV HVAC Systems

Twenty to thirty years ago it was common practice to install a CAV (constant air volume) system in commercial buildings for ventilation and air-conditioning. These types of HVAC systems require high airflow rates and higher amounts of energy for heating and cooling. Thus, increasing utility costs. Therefore, the theory is, that you will achieve considerable energy savings by installing a VAV (variable air volume) system. However, the change is effective only if the entire system is adapted. So, let’s compare CAV vs VAV HVAC systems.

CAV System

Click to see full image.

- A CAV unit operates the fan and compressor at full what is a vav air conditioning system until the temperature drops to a specified setting, then the compressor turns off. The on/off cycling is not efficient what is a vav air conditioning system keeping the space at a constant temperature.

- CAV systems are small and serve a single thermal zone. However, variations such as CAV with reheat, CAV multizone, and CAV primary-secondary systems have the ability to serve multiple zones and larger buildings.

- There are two types of CAV systems commonly used: the terminal reheat system and the mixed air system.

- The terminal reheat system cools the air in the air handling unit down within its zone of spaces. While it cools the air, it is inefficient and costly.

- The mixed air system has two air streams. One for the coldest and one for the hottest needed air temperature in the zone. The two air streams are strategically combined to offset the space’s load. It works well to cool the air. However, it does not control humidity.

VAV Systems

Click to see full image.

- VAV Sytems were developed to meet the varying heating and cooling needs of different building zones. For example, a zone can be either a single room or a cluster of rooms all sharing the same heat gain, and heat loss characteristics.

- The system is efficient at dehumidifying what is a vav air conditioning system space.

- Also available in a multiple-zone system.

- The VAV (variable air volume) system is one of the most energy efficient ways for building air-handling system.

- Offers more precise temperature control as the fan speed varies depending on the temperature what is a vav air conditioning system the space. The compressor regulates the refrigerant flow to maintain a constant air temperature.

- The HVAC industry regards pressure independent VAV systems as the best HVAC system design available. This is a result of improvements in the terminal unit.

So, you might be wondering, what is the biggest difference between CVA vs VAV HVAC systems? Savings. You can save as much as 30 percent in energy costs with a VAV System. In addition, VAV systems are economical to install and to operate. If you have any questions about what type of system your building currently uses, or are interested in converting your old CAV system to a VAV system, contact The Severn Group. We can help you save money today!

Color Fire On September 8, 2016 / Cooling Solutions, HVAC ServicesTags: cooling, designed HVAC systems, office HVAC

VAV Units

VAV units, or Variable Air Volume systems, supply constant temperature air to an area while the volume of air varies as opposed to a conventional HVAC system which has constant volume and varies the air temperature.

Our Variable Air Volume systems are available as a single duct terminal for cooling only or a fan powered terminal for cooling and heating.

Following extensive research on VAV systems involving design engineers and contractors, we have produced a range of fan powered terminal units.

For more friendly and professional advice on VAV units, please get in touch via our contact us page or give us a call on 01842 765657.

Contact us

Model 35SST VAV

Model 35SST Stealth Super Quiet Fan Powered Terminal Unit VAV - The Model 35SST ‘STEALTH’ has been especially designed for the most demanding applications where premium quality design and performance characteristics are desired.

more details

Model D3000 Single Duct VAV

Model D3000 Single Duct Terminal Unit VAV Models: 3001 Cooling or Heating only 30RW Cooling with Hot Water Re-heat 30RE Cooling with Electric Re-heat

more details

Model D3200 Dual Duct VAV

Model D3200 Dual Duct Terminal Unit VAV

more details

Model 35S VAV

The Model 35S provides many standard design features and superior sound performance when compared with other basic model designs. The 35S offers a compact and economical design well suited to the majority of applications.

more details

The 101s: Intro to VAVs

HVAC systems in commercial buildings are getting smarter every day. As technology advances, What is a vav air conditioning system systems must adapt as well. This growing building “smarts” comes with big benefits – energy management tightens, tenant comfort becomes more commonplace, and cost savings grow.

Let’s look at one type of smart HVAC system: VAVs.

What is a VAV system?

VAV stands for Variable Air Volume. In its simplest form, VAV systems use varying airflow at a constant temperature to heat and cool buildings. This is opposite of a CAV (or Constant Air Volume) system, which supplies consistent air flow at varying temperatures to heat or cool a space.

How does a VAV system work?

Let’s break down an example of how a VAV system works. An Air Tel vav Unit (AHU) pushes air into the duct system at roughly 55 degrees Fahrenheit for cooling. The air temperature stays constant in the system, moving through the ductwork to each zone or room of the building. The air eventually goes to the end of each line where it passes through a VAV box. Typically, a VAV box consists of a few simple parts: the damper, the what is a vav air conditioning system, and perhaps a coil for heating and cooling via electricity or water pumps.

As the air passes through these boxes the actuator modulates the damper position which allows different amounts of airflow into the zone. Each VAV box modulates according to the needs of individual zones, meaning it can easily accommodate high demand in one area and low in another, maintaining comfort what is a vav air conditioning system everyone. Additionally, if a damper closes completely, the added system pressure allows the AHU’s fans to slow down, reducing energy use. Or using a bypass damper in the middle of the system, vav mem pressure could trigger that damper to open, relieving system strain into addition ducts or an exterior vent.

Benefits of VAV

This added control via VAVs brings some benefits:

- Precise temperature control

- Reduced compressor wear

- Lower energy consumption

- Less noise

- Additional passive dehumidification

KMC Controls VAV Products

The critical component to these VAV systems is the actuator. KMC Controls offers a variety of VAV products, from our BACnet KMC Conquest VAV controllers to our SimplyVAV controllers, as well as accompanying sensors for each.

These controllers are complex and fully programmable for application-specific functions and any custom application you see fit. They also include integrated alarming, trending and scheduling to make for powerful edge devices that can be controlled via

What is a vav air conditioning system

systems.As buildings are becoming smarter, so should your HVAC system. Having more control means more comfort, lower costs, and smarter buildings.

It is easy and fast and in just a minute, you can start playing the game. The application is stand alone and you can connect it with your Google Play or Facebook account to load your game advancement. Now, you can play at different devices depending on which is convenient to you.

Andy provides solution on how make it convenient for you to play your favorite game at your personal computer. It is updated regularly to check new game versions and to remove bug.