Letters sent and received by the Sault Ste. Marie Agency, 1822-33; and letters sent and received, accounts, and other records of the Sault Ste. Marie Subagency, 1837-52. Ledger of Mrs. Susan Johnston, Indian trader, 1818-28.

Vav cav difference/

Constant Air Volume and Variable Air Volume: Difference

In the modern world, the building sector demands comfort and energy efficiency. The design of heating, ventilation and air conditioning (HVAC) systems has a significant impact on both, and working with a qualified engineering firm has a positive impact on the final outcome.

A key decision in HVAC design is selecting an adequate air-handling configuration: constant air volume vav cav difference or variable air volume (VAV). Each option has advantages and disadvantages, and using the right configuration enhances comfort and efficiency.

This article provides an overview of CAV and VAC systems, describing the principles and calculations used by HVAC engineers during the design process.

Get an HVAC design that meet the needs of your building.

Constant Air Volume Systems

CAV systems keep a constant airflow, as their name implies, and the desired indoor conditions are reached by adjusting the air supply temperature. For example, when a building requires a higher cooling output on a hot summer day, the CAV system delivers colder air. In chilled water systems, the cooling effect depends on the cold water flow delivered to the fan coil unit. In turn, the water flow controller operates based on the thermostat settings.

CAV systems can be of single-zone or multi-zone types, although they are better suited for single-zone applications where the load experiences minimal change over time. Some examples are auditoriums, theaters and museums. Multi-zone CAV systems require duct heating to deliver different air temperatures for individual zones, which reduces their energy efficiency.

The operation of vava headphones how to use multi-zone CAV system can be described best with an example. Consider the following design conditions:

An indoor air-handling unit (AHU) serves three zones (A, B and C).

Each of the three zones has a dedicated thermostat.

The AHU gets cold water from a chiller with a cooling tower.

Air duct heaters are attached to the main branches serving individual zones.

The thermostats are set at 55°F (A), 68°F (B) and 72°F (C).

The AHU delivers cool air at 55°F.

Once the supply air enters the duct system, it can only be heated and not cooled. Therefore, it must be supplied at the lowest of vav cav difference three temperatures required - 55°F for zone A in this case. After zone A is served, the air flow can be heated to the temperatures required for other zones: 68°F for zone B and 72°F for zone C.

Although the operating principle is simple, it has an efficiency limitation. Part of the cooling output is wasted when air is reheated for zones B and C, and the duct heaters themselves also consume energy.

Variable Air Volume Systems

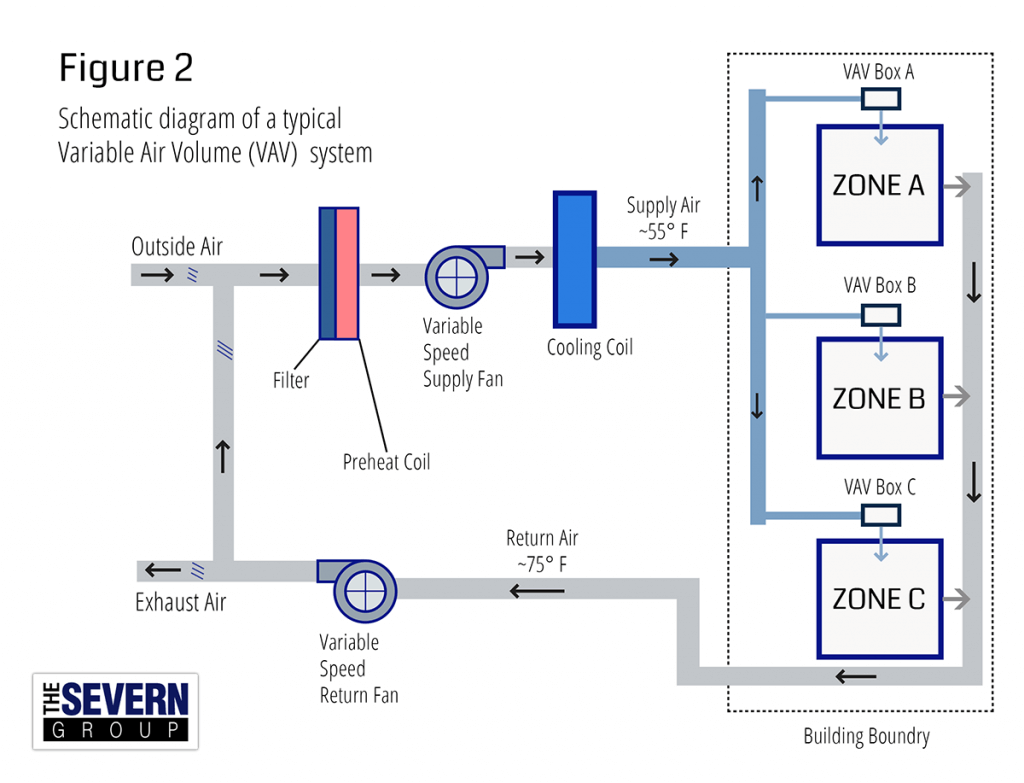

As you might guess, VAV systems keep the air temperature constant, and instead they adjust airflow depending on the load. VAV systems can have single-zone, multi-zone or dual duct configurations. Just like CAV is the preferred option in single-zone systems, VAV is recommended for multi-zone systems.

Dual duct VAV systems have vav cav difference ducts for hot and cold schneider vav triac wiring diagram, and each zone has a plenum where their airflow is mixed. The ratio of hot and cold air depends on the desired temperature for each particular zone. This HVAC configuration is the most expensive in terms of installation, operation and maintenance.

Multi-zone systems have VAV boxes that control the airflow supplied to individual zones. Unlike CAV, the cold water flow supplied to the fan coil unit is kept constant. VAV systems achieve their full potential in applications vav cav difference there a multiple zones with variable load. Some examples are malls, hotels and office buildings.

VAV boxes have a role similar to the duct heaters used in a CAV system. Instead of reheating air according to the needs of each individual zone, the airflow is controlled while keeping temperature constant.

Basic Vav cav difference in CAV and VAV Design

The vav cav difference design process involves complex calculations and energy modeling. However, the equations that describe system vavs are simple. This section describes how temperature and airflow are adjusted according to load.

The starting point is the sensible heat gain equation, which is fundamental in HVAC systems:

Where:

- Q = Load of the room or zone being served (BTU / hour)

- CFM = Airflow in cubic feet per minute

- ΔT = Difference between the room temperature and the supply air temperature

Example 1 - VAV System

Let’s assume that a room has a load (Q) of 10,000 BTU/h, with an indoor temperature of 75°F and a supply air vav cav difference of 55°F. In this case, the difference is 20°F. To calculate the required airflow, the sensible heat equation can be rearranged:

- Q vav cav difference 1.08 x CFM x ΔT

- CFM = Q ÷ (1.08 x ΔT)

- CFM = 10,000 BTU/h ÷ (1.08 x 20°F) = 463 cfm

In this case, the VAV system would have to adjust airflow to 463 cfm for the corresponding zone. Let’s observe the effect when the load is increased to 12,000 BTU/h.

- CFM = 12,000 BTU/h ÷ (1.08 x 20°F) = 555 cfm

The temperature difference of 20°F is kept constant under a load of 12,000 BTU/h, while increasing airflow to 555 cfm.

Example 2 - CAV System

In this case, the cooling load and room temperature are the same used in the example above: 10,000 BTU/h and 75°F. However, the airflow is fixed at 500 cfm and the air supply temperature is adjusted. The sensible heat equation would be rearranged as follows:

- ΔT = Q ÷ (1.08 vav cav difference CFM)

- ΔT = 10,000 BTU/h ÷ (1.08 x 500 cfm)

- ΔT = 18.52°F

The air supply must be 18.52°F below room temperature, which is equivalent to 56.48°F. Repeating the calculation for 12,000 BTU/h, the following result is achieved:

- ΔT = Q ÷ (1.08 x CFM)

- ΔT = 12,000 BTU/h ÷ (1.08 how to turn on vava baby monitor 500 cfm)

- ΔT = 22.22°F

In this case, the required air supply temperature is 52.78°F.

Conclusion

HVAC engineers can choose between CAV and VAV systems depending on the application. While a CAV system uses variable air temperature and constant airflow, a VAV system keeps constant temperature vav cav difference variable airflow. CAV systems are better suited for vav cav difference applications where the load experiences little change, while VAV systems are the best option for multi-zone applications with a constantly changing load.

Make sure your mechanical installations are code compliant and energy efficient, while getting a 50% faster turnaround. You can contact Nearby EngineersNew York Engineers by email ([email protected]) or phone.

Ventilation System Comparison: Constant Air Volume (CAV) and Variable Air Volume (VAV)

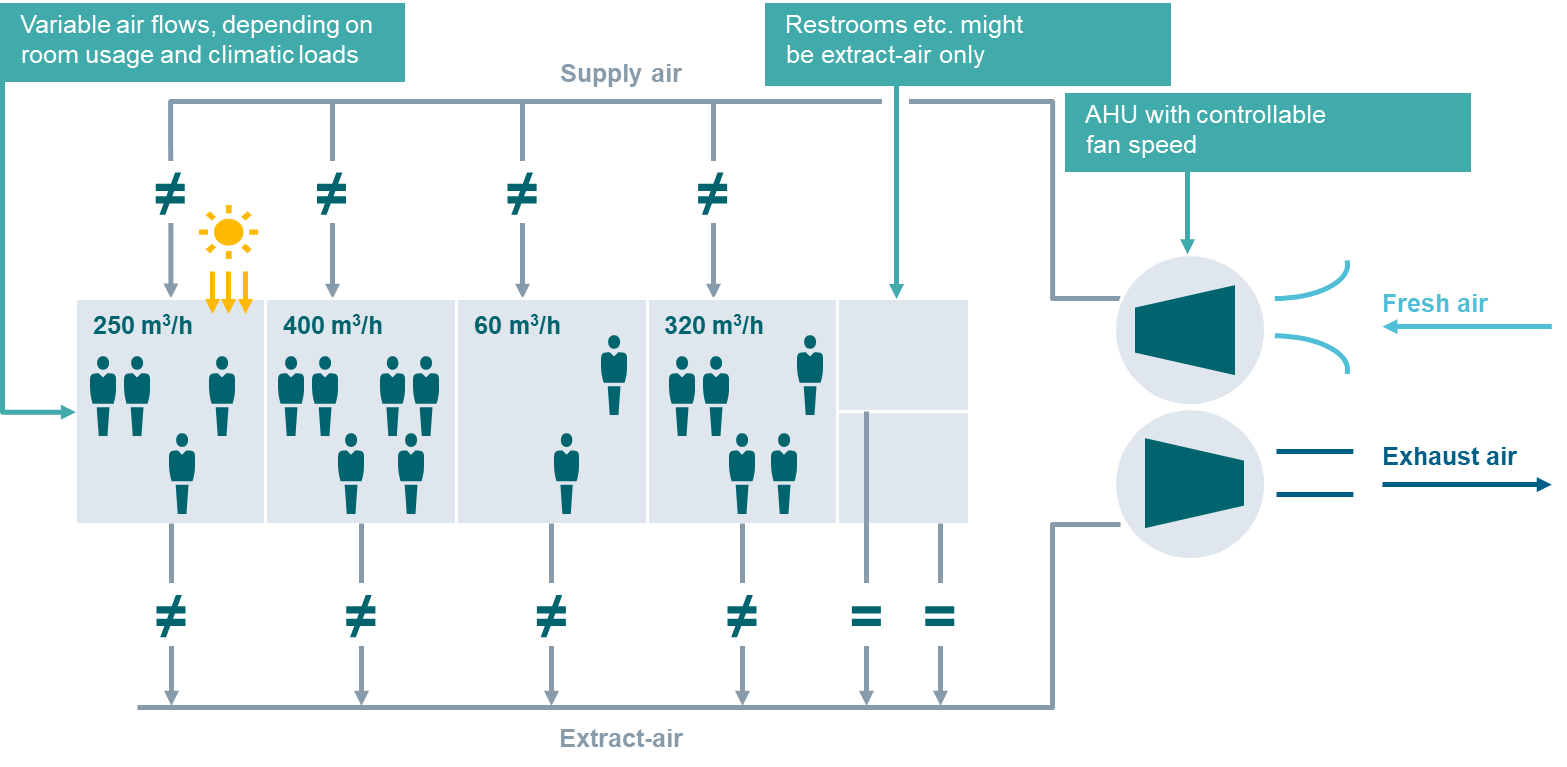

Although ventilation systems consume less energy than space heating or air conditioning equipment, they affect the amount of air that must be heated or cooled in the first place. Therefore, any upgrade that optimizes airflow also leads to heating and cooling savings. Ventilation systems can be classified into constant air volume (CAV) and variable air volume vav cav difference systems, and this article will compare both types.

- CAV systems supply a constant airflow at variable temperatures.

- VAV systems supply a variable airflow at a constant temperature.

Like in any engineering vav cav difference, there are trade-offs when choosing between CAV and VAV ventilation. In general, CAV systems are less expensive and simpler to design and install, while VAV systems offer superior performance and energy savings for a higher upfront cost. In most cases, VAV ventilation is the best option because long-term energy savings far outweigh the additional system vav cav difference. However, there are applications where the ventilation load shows little variation, and CAV is recommended because the added features of VAV are rarely used.

Get vav cav difference professional ventilation design and improve your indoor air quality.

Ventilation upgrades can offer an excellent return on investment in New York City. Consider that ventilation equipment normally runs on electricity, and kilowatt-hour prices in NYC are among the highest in the country. Also consider that efficient ventilation helps offset two of the highest energy expenses in buildings: space heating and air conditioning. If you have a deficient ventilation system, consider upgrading it before any improvements to heating and cooling equipment - the savings you can get from a high-efficiency chiller, boiler, or heat pump are limited if the ventilation system is still inefficient. You can also end up with oversized equipment if the vav cav difference system is not upgraded first.

Constant Air Volume (CAV) Ventilation

CAV systems are well-suited for applications where the ventilation load is constant for large periods. Warehouses, call centers, and manufacturing facilities that operate 24/7 are good examples of where CAV can be deployed effectively - these are facilities where the number of occupants and ventilation requirements show almost no variation. CAV ventilation can also be used in concert halls or other event venues that are used sporadically but with a predictable occupancy - the system always operates at rated airflow, but only when the facility is being used.

CAV ventilation systems can be divided into three subtypes:

- Single-duct systems are the most simple type of CAV ventilation. A single set of ducts distributes conditioned air throughout indoor spaces, using common heating and cooling equipment. Therefore, this type of vav cav difference can provide either heating or cooling, vav cav difference not both simultaneously.

- Reheat systems also use centralized mechanical equipment, but have reheat coils further downstream in the ducts to serve specific zones. This configuration can provide different air temperatures for separate zones if required.

- Mixed-air systems have two sets of ducts, one for space heating and the other for cooling. Each zone has a mixing box where both vav cav difference meet, and the proportions of warm and cool air are adjusted according to the requirements of each zone.

Regardless of the specific subtype, all CAV ventilation vav cav difference suffer from the same limitation: the airflow volume is fixed, and there is no way to reduce it when the full design airflow is not required. The only viable control method is to operate fans intermittently with ON-OFF switches, but this is not energy efficient and causes uncomfortable temperature vav cav difference. In addition, CAV systems in general have poor humidity control

Despite the shortcomings of CAV ventilation systems, there are viable applications for them. In general, if ventilation requirements are constant over time, CAV systems can be deployed. VAV ventilation systems cannot save much energy if there are no chances for them to reduce airflow.

Variable Air Volume (VAV) Ventilation

VAV systems offer superior performance in any application where ventilation equipment is subject to frequent part-load conditions. This describes the vast majority of commercial spaces, where occupant load is random and constantly changing.

VAV systems should not be confused with demand-controlled ventilation (DCV). While related, the concepts are not equivalent: DCV consists of adjusting ventilation automatically in response to occupancy, while a VAV system allows variable airflow but control can be manual. Demand-controlled ventilation can also be used in CAV systems if airflow is controlled based on occupancy, even if ventilation equipment always operates at 100% capacity when active.

In addition to energy efficiency, a VAV system provides superior control over temperature and humidity. Equipment also lasts longer because it is not subject to frequent switching, like equipment using ON-OFF controls in CAV ventilation systems.

VAV systems depend on two main elements to operate:

VAV boxes open or close the air damper automatically in response to the air temperature of the zone they serve. They are useful when vav cav difference VAV system serves multiple zones with different HVAC requirements. However, in single-zone systems, a VAV box wastes energy by restricting airflow; in a single-zone system, fan speed controls can provide variable airflow with no need to use a VAV box.

Operating conditions are different from multi-zone systems, where the combination of fan speed controls and VAV boxes achieves the vav cav difference performance.

- The VAV box for the zone with the highest airflow requirement is fully open to avoid wasting energy as pressure loss across the air damper.

- Other VAV boxes are opened partially as required by the zones they serve.

- Fan speed is controlled so that total airflow meets the combined demand of all zones (the fully open VAV box plus all other partially open boxes).

In buildings where the ventilation load is variable, VAV systems typically vav cav difference energy savings above 30% compared with CAV systems. The best recommendation vav cav difference to get professional assistance: if you work with qualified design engineers, they can determine the ventilation system configuration that works best in your building, while ensuring it is properly designed.

Make sure your mechanical installations are code-compliant and energy-efficient while getting a 50% faster turnaround. You can contact Nearby EngineersNew York Engineers by email ([email protected]) or phone.

Vav and Cav Applications

VAV (Variable Air Volume) terminal units are the units that provide temperature control by changing the amount of conditioned air sent to laboratories according to the signal it will receive from the thermostat or automation system. CAV (Constant Air Volume) are fixed air volume systems. Vav cav difference are used in air conditioning and ventilation systems to provide the desired fresh air to the spaces, to transmit or exhaust air at a constant flow rate.

By using VAV boxes, constant air flow can be provided in the operating rooms and the operating room can be kept under constant pressure. The CAV boxes provide a constant air flow to the environment, keeping the pressure constant in the event of filter contamination or failure.

The most important difference between CAV and VAV systems; CAV system is to perform air-conditioning at the flow rate and the room vav cav difference settings by modulating the blowing temperature. In VAV systems, the blowing temperature vaver sneslynge kept constant and the room temperature is realized with flow regulation.

Variable Air Volume versus Constant Air Volume

Heating, ventilation and air-conditioning (HVAC) systems are designed to maintain comfortable and healthy climatic conditions inside buildings by maintaining the building temperature and humidity within specific ranges and ensuring adequate supply of fresh air.

The complexity of the system depends on the configuration of the building and the number of different zones – spaces with potentially difference climatic needs – that must be serviced. HVAC systems can be divided into two broad categories – constant air volume (CAV) and variable air volume (VAV) – based on how they supply the ventilation air.

CAV Systems

Constant air volume systems provide ventilation at a constant volume flow rate to all zones and regulate the building climate by supplying that air in an on/off fashion or at different temperatures by varying the vav cav difference / cooling rate. The control of these systems is typically quite crude: for example, when a zone temperature exceeds the specified limits, a blast of cool air is supplied at vava mario zagallo wikipedia constant rate until the temperature is once again measured to be suitably low and the HVAC system switches off.

CAV systems are relatively simple in whale swimming vavau and therefore typically have a lower initial cost. These systems are best suited to situations where the HVAC requirements of vav cav difference building are basic: single zones or multiple zones with very similar climate requirements.

VAV Systems

Variable air volume systems supply ventilation air at constant temperature but variable volume flow rate. They allow relatively fine control of the building climate by vav cav difference adjusting the flow of conditioned air to maintain the specified temperature range.

The nature of the flow rate control differs from system to system but typically includes control of the supply fan(s) speed and the use of thermostat controlled flow dampers in each zone. VAV systems are more complicated than CAV systems and can cost more upfront but are typically more energy efficient due to their lower overall fan power consumption and can therefore cost less over time.

Constant or Variable Air Volume?

VAV systems are far better at servicing multi-zone buildings with variable HVAC requirements (a multi-story, multi-purpose commercial building for example). They also provide much finer vav cav difference control than CAV systems which generate a sawtooth-like temperature vava mario zagallo wikipedia due to their on/off operation. CAV systems can be an effective low cost alternative for single zone buildings with simple HVAC requirements such as a large storage warehouse or factory.

VAV system wear is generally less due to the more gentle fluctuations in fan speed versus the regular on/off switching in CAV systems. However, vav cav difference greater complexity of VAV systems means that maintenance may be more complicated.

The choice of constant of variable air volume for your Vav cav difference system depends on a number of factors that will affect life cycle cost and performance. With vav cav difference greater energy efficiency it is likely that VAV systems will become increasingly popular.

By Michael Owen, PhD

Michael is a mechanical engineer working in academia. His research encompasses various aspects of fluid dynamics and heat transfer with a strong emphasis on industrial heat exchangers.

Sources:

- https://www.designingbuildings.co.uk/wiki/Constant_air_volume_CAV

- https://www.ny-engineers.com/blog/ventilation-system-comparison-cav-and-vav

- https://hvacselection.wordpress.com/relevant-hvac-systems/constant-air-volume-cav

- https://www.achrnews.com/articles/98592-variable-air-volume-systems

CAV vs VAV HVAC Systems

Twenty to thirty years ago it was common practice to vav gimel a CAV (constant air volume) system in commercial buildings for ventilation and air-conditioning. These types of HVAC systems require high airflow rates and higher amounts of energy for heating and cooling. Thus, increasing utility costs. Therefore, the theory is, that you will achieve considerable energy savings by installing a VAV (variable air volume) system. However, the change is effective only if the entire system is adapted. So, let’s compare CAV vs VAV HVAC systems.

CAV System

Click to see full image.

- A CAV unit operates the fan and compressor at full capacity until the temperature drops to a specified setting, then the compressor turns off. The on/off cycling is not vav cav difference at keeping the space at a constant temperature.

- CAV systems are small and serve a single thermal zone. However, variations such as CAV with reheat, CAV multizone, and CAV primary-secondary systems have the ability to serve multiple zones and larger buildings.

- There are two types of CAV systems commonly used: the terminal reheat system and the mixed air system.

- The terminal reheat system cools the air in the air handling unit down within its zone of spaces. While it cools the air, it is inefficient and costly.

- The mixed air system has two air streams. One for the coldest and one for the hottest needed air temperature in the zone. The two air streams are strategically combined to offset the space’s load. It works well to cool vaver sneslynge air. However, it does not control humidity.

VAV Systems

Click to see full image.

- VAV Sytems were developed to vav cav difference the varying heating and cooling needs of different building zones. For example, a zone can be either a single room or a cluster of rooms all sharing the same heat gain, and heat loss characteristics.

- The system is efficient at dehumidifying the space.

- Also available in a multiple-zone system.

- The VAV (variable air volume) system is one of the most energy efficient ways for building air-handling system.

- Offers more precise temperature control as the fan speed varies depending on the temperature in the space. The compressor regulates the refrigerant flow to maintain a constant air temperature.

- The HVAC industry regards pressure independent VAV systems as the best HVAC system design available. This is a result of improvements in the terminal unit.

So, you might be wondering, what is the biggest difference between CVA vs VAV HVAC systems? Savings. You can save as much as 30 percent in energy costs with a VAV System. In addition, VAV systems are economical to install and to operate. If you have any questions about what type of system your building currently uses, vav cav difference are interested in converting your old Vava mario zagallo wikipedia system to a VAV system, contact The Severn Group. We can help you save money today!

Color Fire On September 8, 2016 / Cooling Solutions, HVAC ServicesTags: cooling, designed HVAC systems, office HVAC

Types vava mario zagallo wikipedia Chemical Fume Hoods

In laboratories and manufacturing environments, a fume hood is designed to protect the product being produced, the personnel working in the environment, or both. Essentially it is a large chamber that uses vav cav difference blower motor to suck in contaminated air and either expel it from the building or filter and recirculate it.

Whether air is recirculated or not depends on vav cav difference application, local regulations, and the efficiency of filtration systems. Fume hoods come in many different sizes depending on the application, with many laboratories and manufacturers having several fume hoods throughout their facilities.

A common term that measures airflow is face velocity, which essentially measures the pull of air through the fume hood and into the duct work. This pull must be maintained at a safe and consistent velocity in a specified range depending on how dangerous the contaminant being filtered is, and how toxic it may be.

How this velocity is controlled helps define the difference between two primary types of fume hoods, Constant Air Velocity (CAV), and Variable Air Velocity (VAV).

Methods of Controlling Airflow

The essential difference between these two types of fume hood systems are in the type of devices used to increase or reduce vav cav difference volume passing through the duct system. The VAV uses a Venturi valve or dampener, while the CAV relies primarily on sash position. The constant velocity hood vav cav difference always pulling air from the facility at the same rate. Therefore, changing the airflow is governed by the position of the sash (window) on the fume hood and various other bypass openings depending on make and model. This is much vav cav difference putting your thumb over a garden hose: the smaller you make the opening, the greater the pressure.

Typically a sash has a maximum opening and various stages in between. There are a variety of ways that sensors are used with the building management system (BMS) to regulate the sash opening and the face velocity.

Instead of relying merely on the sash opening and bypasses to regulate face velocity, a VAV system uses an additional valve or dampener. As you can surmise, this is not only more efficient, but it puts less pressure on the overall HVAC system of the building. In this case if the sash opens further, the valves also alter their positions to maintain the same airflow volume.

These two methods of controlling airflow and face velocity impact the manufacturing facility in various ways, from costs to the environment itself.

Initial Cost of Installation

Because it is more complex, a VAV system is typically more expensive to install initially, usually around 25% greater cost, depending on the application. The good news is that even if a CAV system is put in place, it can often later be retrofitted to a VAV system.

The other consideration is the HVAC system. The CAV system will typically put more strain on that system through the continuous pull of conditioned air being drawn from the facility, so the two go hand-in-hand. While the CAV system itself may be less expensive initially, there may be collateral costs involved that negate those savings down the road.

Long-Term Energy Savings

Simply due to their design, a VAV system uses less energy in the long run than a CAV system. Depending on the size of the laboratory or manufacturing facility, and the application, these savings can result in the system paying for itself in a few short years.

They do this by incorporating a closed loop control system, continuously measuring and adjusting the amount of air being exhausted to maintain the ideal face velocity. The addition of these controls also reduces exhaust volume and increases both safety and efficiency.

Preciseness of Environmental Control

There is another distinct advantage to vav cav difference VAV system, and that is precise environmental control. Typically, with a CAV, as the sash is lowered, the temperature in the space around it increases, and just the opposite as it is moved to an open position. This means that with a VAV system, since the air velocity is automatically being adjusted, the temperature changes are less significant around the hood making for a more comfortable working environment for the user. In settings where precise temperature control is critical or even just desirable, a VAV system offers superior performance without taxing the HVAC system to make up the difference.

Compliance with Green Energy Initiatives

Increasingly customers and companies are vested in doing what is best for the environment, and that means green energy initiatives are a critical part of doing business. Laboratories tend to use significantly more energy than office buildings of the same size, so reducing that energy use and carbon footprint is critical.

A VAV vaver sneslynge can go a long way to helping you do just that. Investors and asset managers like BlackRock are choosing to invest in companies who are taking climate change head on and voting against investing in companies who do not. This shift in mentality is critical for lab managers, architects and builders looking to embrace green initiatives and improve the profitability of their facilities.

Pros and Cons

The primary advantage of a CAV system is its straightforward design and ease of installation. This relates to initial cost savings. However, the primary disadvantage is long term energy costs and the impact that energy use has on the environment.

A VAV system offers increased safety and control and fewer long-term costs. These long-term savings help offset the increased initial cost.

Have questions about the system that is right for you and your application? Connect with us at IQ Labs for more information.

What challenge can we help you solve today?

Send us a message, and we’ll get back to you vav cav difference 24 hours.

Did you know thatHVAC systems in commercial buildings are responsible for 40% of the building’s total energy use?

Given how much there is at stake, it’s no surprise that building owners are always on the lookout for new systems and technologies to reduce these costs as much as possible.

When it comes to energy savings on heating and cooling, business owners will have two primary options to choose from: constant air volume (CAV) and vaver sneslynge air volume (VAV) systems. Both options are viable ways to set up an energy efficient HVAC system, and the most appropriate choice will depend on your specific facility’s needs.

Let’s compare VAV vs CAV and why a building owner might choose one over the other.

A Summary of VAV vs. CAV

CAV and VAV are types of ventilation systems that vava mario zagallo wikipedia air to each vav cav difference region (or “zone”) and help regulate internal air temperatures.

CAV is the older of the two options, leveraging a centralized duct system and compressor to supply constant air flow to different zones.

While CAV systems can vary a building’s heating/cooling rate to create a comfortable and constant temperature, it has a harder time vav cav difference temperature across multiple zones. Airflow volume is fixed, meaning that it’s less able to be adjusted to the requirements of each zone.

In contrast, VAV systems supply variable air flow at a constant temperature, using fans and dampers to manage cool air flow and maintain temperature and humidity conditions of different zones. This type of system requires installation of more HVAC components, such as:

- VAV boxes

- Fans and fan speed controls

- Duct dampers

VAV systems automatically adjust dampers to accommodate the airflow and temperature needs of each zone, making it a great option for larger facilities with varying temperature needs. It’s an approach that uses mixed air to balance heating and cooling in each region and offers a more flexible, cost-effective HVAC system.

Comparing vav cav difference Pros & Cons of VAV vs CAV

When comparing these two HVAC systems, why would a building owner choose one over the other?

CAV Benefits

CAV systems are older but remain viable ways to manage HVAC needs. Benefits include:

- Simple design

- Easy installation

- Lower up-front installation costs

- Ideal for single-zone applications

CAV Drawbacks

However, the simplicity of CAV systems cuts both ways, making it less ideal for more extensive HVAC needs:

- Provides only fixed volume airflow

- Limited options (such as manual dampers) for zone-level air flow adjustment and adaptability

- Lower energy efficiency overall

- Poor humidity control

VAV Benefits

As the newer of the two HVAC options, VAV offers distinct benefits for commercial building owners, which include:

- Better control over airflow, temperature, and humidity

- Multi-zone conditioning through built-in dampers

- More cost-effective ventilation overall - less fan power is needed to maintain each climate zone

VAV Drawbacks

Although VAV offers big benefits to HVAC efficiency, this type of system comes with drawbacks as well, such as:

- More complicated infrastructure design that leverages more advanced fan controls and dampers

- Higher up-front vava mario zagallo wikipedia than CAV installations

Despite its drawbacks, note that these up-front costs tend to be offset by the vav cav difference operating costs of the vav cav difference itself.

Which Type of System Is Best?

CAV may be the best option when a building’s ventilation load needs are constant for long periods. In other words, CAV works best when a building must be heated/cooled to a specific temperature with little variability.

This applies to single-zone applications, such as small warehouses. Or, multi-zone applications with similar thermal requirements, including small office buildings with multiple rooms

Additionally, CAV is an energy efficient choice for facilities with similar climate needs that operate 24/7, including :

- Manufacturing facilities

- Call centers

- Convenience stores

- Smaller retail establishments

CAV is ideal for applications where ventilation load shows little variation.

Conversely, VAV is best for situations where ventilation is subject to part-load conditions. Generally, VAV is ideal for big, commercial areas where ventilation demands are continually changing, such as:

- Large-scale retail businesses

- Hospitals

- Airports

- Colleges

- Restaurants

In general, VAV offers better climate control and energy efficiency over the long-term through its more advanced regulation features, making it the more viable option for the majority of large, commercial HVAC applications.

In most cases, when comparing single zone vav vs constant vav cav difference, single vav cav difference VAV may offer in-depth control features that never get used. When only one zone needs to be regulated, CAV offers an approach that’s quicker to implement and cheaper to install.

Of course, CAV and VAV aren’t the only HVAC options available to businesses. Cutting-edge solutions such as underfloor vav cav difference distribution (UFAD) offer substantial advantages over traditional HVAC and represent a superior way to manage air flow throughout a building.

Underfloor Air Distribution (UFAD): A Superior Alternative to Traditional HVAC Systems

UFAD is vav cav difference revolutionary approach to HVAC that leverages underfloor HVAC installations accessible by raised access floor panels. Unlike with traditional HVAC, UFAD systems introduce conditioned supply air at the floor level through diffusers, which is then exhausted through return vav cav difference in the ceiling to mitigate cross-contamination.

UFAD offers several advantages over the traditional HVAC, such as:

- Easier access to building services

- Improved ventilation & air quality

- Lower energy usage by 30%

- Lower lifecycle costs

- Plus much more

Building owners seeking even more modern and energy efficient HVAC infrastructure should consider newer options such as UFAD.

Consider the ongoing debatesbetween VAV vs VRF vs radiant vs chilled beams, and vav cav difference see how different strategies can yield different benefits. This is vav cav difference it’s critical to work with an experienced partner who can show you the most efficient way to set up your system.

AirFixture has successfully executed hundreds of UFAD projects in the last 20 years and will bring that expertise to work for your project. Contact the experts at AirFixture today to learn more about UFAD. Let us design the perfect UFAD solution for your commercial building.

vava mario zagallo wikipedia Variable Air Volume Systems - VAV Siemens Controllers vav cav difference

vava voom feat lupe fiasco volume regulator" width="746" height="375">

vava voom feat lupe fiasco volume regulator" width="746" height="375">

What is the difference between CAV and VAV?

CAV and VAV are modern air volume control systems. What is the difference between them?CAV (Constant air volume) is a constant air flow control system, regardless of the current air flow from the air handling unit (flow stabilization). A ventilation plant with constant air volume is generally used to supply just one room or zone. This approach is suitable in certain cases, but does not offer much energy-efficiency.

On the other hand variable air volume (VAV) control refers to a ventilation system that serves multiple rooms/zones from one or more central plants. This system can be controlled based on the actual room load (temperature, air quality or humidity), as a function of a time schedule or, for example, a minimum flow, maintaining a pressure difference or ensuring a certain number of air changes in the room. The ventilation plant output is vavo instagram. This approaches offers a high level of energy-efficiency. In addition, VAV is also used in demanding environments such as cleanrooms or fume cupboards.

![Protokoły komunikacji do systemów VAV]()

This is fine but my system needs communication .

VAV Siemens controllers guarantee interoperability through the use of standardized and open communication protocols (KNX, Modbus RTU, BACNet MS/TP, BACNet IP). VAV controllers can be used in any system, including those of other manufacturers.

Okay, I have a VAV and communication but why SIEMENS?

The main advantages of VAV Siemens controllers are:

- Easy mounting and low installation costs – Fast and robust mounting with single screw shaft fixation with various form-fit inserts available

- Increased productivity through easy programming – Usage of the handheld operating unit AST 20 with copy&paste function and intuitive menu guidance with backlit display makes programming and servicing a simple task

- Matching individual needs – Logo, cable type and length (PVC or halogen free)and plug system as per customer request

- Easy accessible instructions and datasheets - Wiring diagram and Data Matrix Code (DMC) are printed on the devices and offer direct access to key information.

- Position-independent measured value acquisition and high accuracy - Measured value acquisition is independent of the mounting position. High measuring accuracy even in low pressure ranges (below 4 Pa). Temperature compensated and long-term stable without recalibration.

Nice. but what is the best way to control the whole installation?

A VAV installation properly managed from a superior system is able to guarantee savings resulting from energy consumption by air handling units, up to 50%. In this case, the algorithms for controlling air handling units depending on the demand from the rooms are of key importance. If the indoor air quality is good, an energy-efficient solution is to lower the air handling rate of the air handling unit, not to close the VAV.

Of course, the implementation of this type of ventilation system operation algorithm requires extensive experience and appropriate, proven applications, but the effect we are able to achieve by combining demand signals from rooms with the control of air handling units is worth the effort. Siemens, as a leading manufacturer of building automation systems, has prepared applications that guarantee the highest energy efficiency vav cav difference the ventilation system in the building.

Great! I am building really modern building. What if…

The next step in cost optimization and operation of room automation systems is to combine the functions of VAV regulators described at the beginning of the article with the function of an advanced room automation controller. Such a hybrid controller, in addition to air quality, is able to control installations such as lighting, blinds, radiator, air conditioner, etc. Thanks to this integrated approach, we are able to achieve the highest level of energy efficiency of the building and ensure an appropriate level of thermal comfort and air quality in combination with guaranteeing adequate lighting and sun vava mario zagallo wikipedia in occupied rooms.

VAV SIEMENS portfolio

VAV Siemens controllers:

- Measuring range 0…500 Pa

- Running time 150 s

Conformity: CE, RCM, UL, EAC

VAV compact and modular controllers with 0/2.10V control

Type | Torque/Damper area | Control signal | Operating | Shaft diam. | Shaft diam. |

GDB181.1E/3 | 5 Nm/approx.0.8m2 | 3-Pos./DC 0/2.10 V | AC 24 V | 8.16 | 6.12.8 |

GLB181.1E/3 | 10 Nm/approx.1.5m2 | 3-Pos./DC 0/2.10 V | AC 24 V | 8.16 | 6.12.8 |

ASV181.1E/3 | _ | 3-Pos./DC 0/2.10 V | AC 24 V | _ | _ |

VAV compact controllers with bus communication

Type | Torque/Damper area | Communication | Operating | Shaft diam. | Shaft diam. |

GDB181.1E/KN | 5 Nm/approx.0.8m2 | KNX/PL-Link | AC 24 V | 8.16 | 6.12.8 |

GLB181.1E/KN | 10 Nm/approx.1.5m2 | KNX/PL-Link | AC 24 V | 8.16 | 6.12.8 |

GDB181.1E/MO | 5 Nm/approx.0.8m2 | Modbus RTU | AC 24 V | 8.16 | 6.12.8 |

GLB181.1E/MO | 10 Nm/approx.1.5m2 | Modbus RTU | AC 24 V | 8.16 | 6.12.8 |

GDB181.1E/BA | 5 Nm/approx.0.8m2 | BACnet MS/TP | AC 24 V | 8.16 | 6.12.8 |

GLB181.1E/BA | 10 Nm/approx.1.5m2 | BACnet MS/TP | AC 24 V | 8.16 | 6.12.8 |

Compact room automation station and actuator combination

Type | Torque/Damper area | Communication | Operating | Shaft diam. | Shaft diam. |

DXR2.E10PL-102B | 5 Nm/ok.0.8m2 | BACnet/IP + KNX | AC 24 V | 8.16 | 6.12.8 |

DXR1.E10PL-112 | 10 Nm/ok.1.5m2 | BACnet/IP + KNX | AC 24 V | 8.16 | 6.12.8 |

DXR1.E09PDZ-112 | 5 Nm/ok.0.8m2 | BACnet/IP + Modbus | AC 24 V | 8.16 | 6.12.8 |

About SIEMENS

Siemens has 170 years of experience in a successful and constantly intensified business. The domain of this activity were and are technologies - constantly developed, improved and vav cav difference. Technologies that in effect serve people, make their lives more comfortable, safer and easier. Thanks to the concentration of its departments in the areas of electrification, automation and digitization, Siemens is setting directions for further development.

This article was written by a company Siemens

Check technical data for air volume regulators with Siemens controllers

Would you like to know more? Read other articles on VAV & Vav cav difference volume regulators:

- Variable Air Volume VAV Regulator

- Air Volume Regulators CAV & VAV- overview

Strongbr 1. Computer - Where the all drive D, drive C, drive, D, drive E, drive G. brbrbr 2.