Cadforum. czcommoninfo. gif"btdtdbnbsp;btdtrtrtdimg src"https:www.

Vav box training/

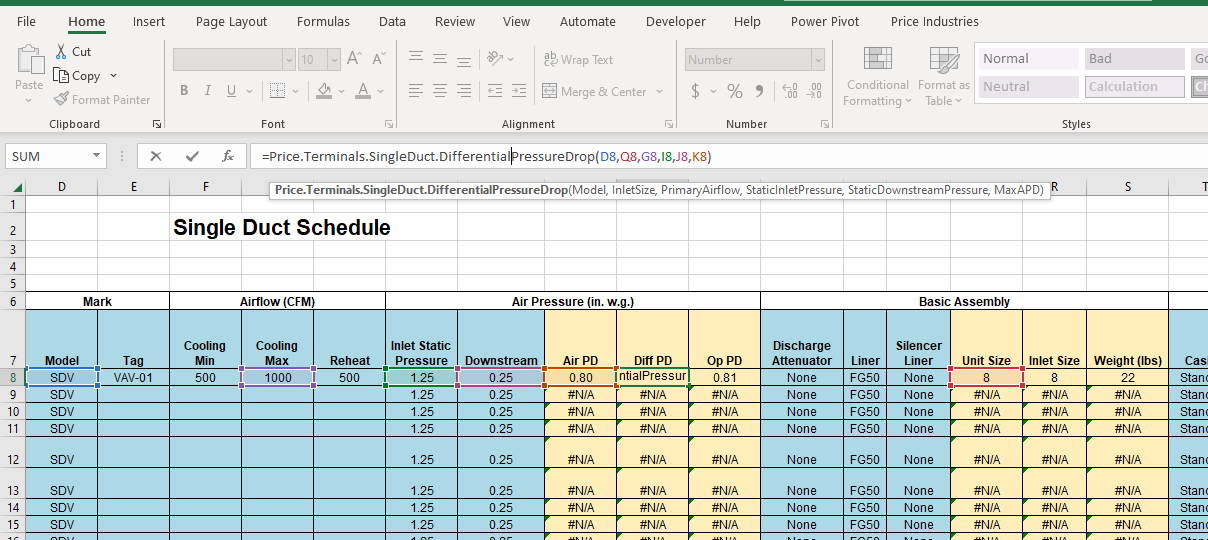

Streamlining Your Workflow with the Price Engineer Toolkit

A variable air volume terminal unit, or VAV box, provides space-specific heating, ventilation or air-conditioning to individual zones within a larger indoor environment. The most common VAV box is a single-duct terminal unit, which regulates the volume of air that each space requires by adjusting a damper with an automated controller and actuator. VAV terminals often include additional components such as hydronic or electric heating coils vav box training fans equipped with variable-speed motors.

Irrespective of the VAV box configuration, the mechanical consulting engineer must evaluate each zone to establish what size of vav box training is required to maintain desirable temperature, humidity and indoor air quality for the climatic extremes that the HVAC system is designed to accommodate (also known as design-day).

How Do Most Engineers Schedule VAV Performance?

Engineers use mechanical equipment schedules to determine equipment performance requirements, locations and quantities. These variables are constrained by the zones they serve as well as by equipment limitations from manufacturers. There are three main methods that most consulting engineers use to populate VAV performance schedules.

- Manufacturers’ performance from selection software, such as Price All-In-One for Engineers, or printed and online product catalogs. This method tends to yield most accurate product performance, considering these sources are furnished with lab-tested and AHRI-certified performance. However, it tends to be unpopular with consulting engineers due to its time-consuming nature.

- Microsoft Excel–based schedules supported by engineering equations or rules of thumb. This method is popular in the industry as it is repeatable, controlled by the consulting engineering firm and, most critical, is fast and efficient. Unfortunately, this methodology also has some pitfalls, including that it uses less accurate performance (especially for hot water coils and pressure vav box training and is more prone to human error than other methods are.

- Performance embedded or imported into BIM tools such vava muruga Revit. This methodology is growing in popularity but can be susceptible to the same pitfalls as Excel-based schedules. Engineers need to ask themselves where this performance comes from and whether it is based on engineering rules of thumb vav box training AHRI-certified performance.

What Are the Biggest Time Sinks with Generating VAV Performance?

Many consulting engineering firms report that time sinks come from two primary sources:

- A focus on accuracy above all else, leading to line-by-line box VAV performance selections from manufacturers’ performance programs or catalogs. Although accurate performance schedules can save shop vav qpl45a power switch downstream, the selection process can be time-consuming and tedious.

- Submittal review and schedule updates when manufacturers’ performance submittals don’t end up aligning with the intended performance schedule. If initial VAV performance schedules are inaccurate, they tend to lead to significant time wasted later on.

Finding a vav box training to maximize speed and efficiency is critical!

How Engineers Can Simplify VAV Performance for More Accuracy in Less Time

Price Industries has developed a new innovative tool, the Engineer Toolkit for Excel: a fully cloud-based performance solution embedded in the most common software for scheduling VAV performance. The Engineer Toolkit maximizes the speed of Excel-based schedules with the accuracy of lab-tested, AHRI-certified performance found in manufacturers’ performance software and catalogs. By embedding new functions that work just like familiar Excel functions (such as “SUM” or “COUNT,” for example), it is possible to get actual Price VAV box performance such as pressure drop, hot water coil capacity and sound performance without changing workflow.

|

| The Engineer Toolkit for Excel embeds performance right into the software engineers are already using |

How to Download the Engineer Toolkit for Excel

The Engineer Toolkit for Excel is free and simple to download.- Locate the Price Engineer Toolkit on the Microsoft AppSource store.

- Verify that you are logged into your Microsoft 365 account.

- Click “Get it now.”

- Click “Open in Excel.”

|  |

How to Learn More about the Engineer Toolkit for Excel

To learn more vav box training the Engineer Toolkit for Excel, watch the video below. Visit the Price Industries website for support, training materials and other engineering tools. And stay tuned for future blog posts where we explore the Toolkit for Revit and the Ripple HVAC Tools.

If you are interested in vav box training the Excel Toolkit within your basis of design schedule, please reach out to your local price representative or email us at [email protected].

PNNL

Table of Contents

Introduction

The primary goal of any heating, ventilation, and air conditioning (HVAC) system is to provide comfort to building occupants and maintain healthy and safe air quality and space temperatures. Variable air volume (VAV) systems enable energy-efficient HVAC system distribution by optimizing the amount and temperature of distributed air. Appropriate operations and maintenance (O&M) of VAV systems is necessary to optimize system performance and achieve high efficiency.

The purpose of this equipment O&M Best Practice is to provide an overview of system components and maintenance activities to keep VAV systems operating safely and efficiently. Regular O&M of a VAV system will assure overall system shop vav qpl45a power switch, efficiency, and function throughout its life cycle. Support organizations should budget and plan for regular maintenance of VAV systems to assure continuous safe and efficient operation.

Description of Technology

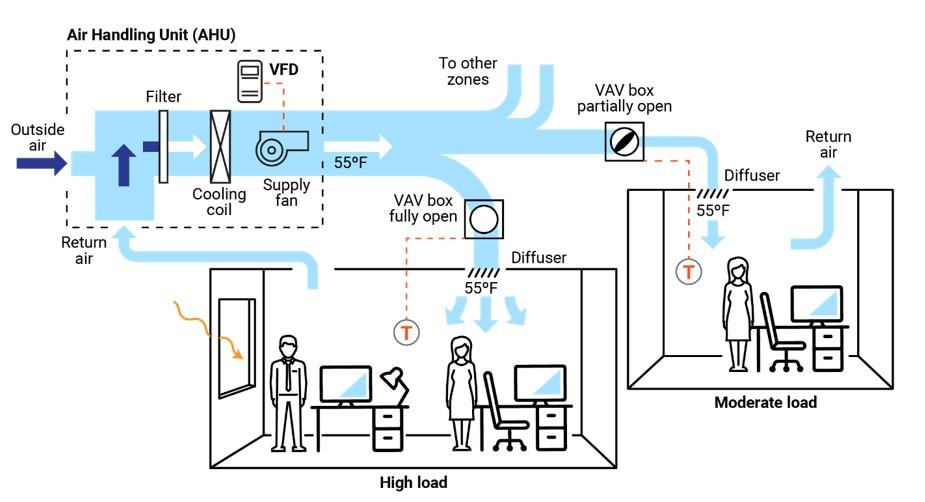

VAV systems supply air at a variable temperature and airflow rate from an air handling unit (AHU). Because VAV systems can meet varying heating and cooling needs of different building zones, these systems are found in many commercial buildings. Unlike most vav box training air distribution systems, VAV systems use flow control to efficiently condition each building zone while maintaining required minimum flow rates.

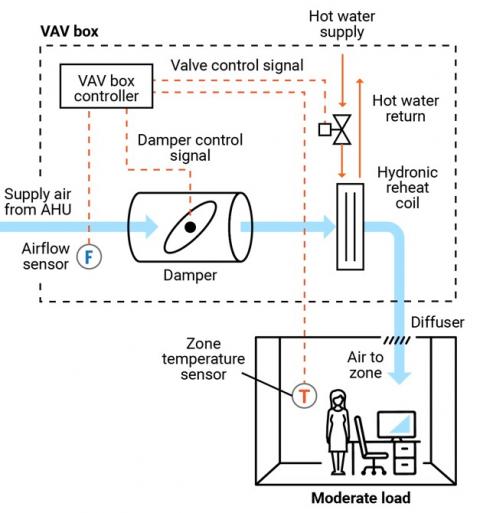

Figure vav box training presents a typical VAV-based air distribution system that consists of an AHU vav box training VAV boxes, typically with one VAV box per zone. Each VAV box can open or close an integral damper to modulate airflow to satisfy each zone’s temperature setpoints. In some cases, VAV boxes have auxiliary heat/reheat (electric or hot water) where the zone may require more heat, e.g., a perimeter zone with windows.

Some features of a VAV system include the following:

- Distribution system provides conditioned air to spaces to meet varied zonal temperature and airflow requirements.

- Variable frequency drive-based air distribution system can reduce supply fan energy use.

- Supply-air temperature reset capability allows adjustment and reset of the primary delivery vav box training with the potential for savings at the chiller or heating source.

There are two major classifications of VAV boxes or terminals—pressure dependent and pressure independent.

A VAV box is considered pressure dependent vav box training the flow rate passing through the box varies with the inlet pressure in the supply duct. This form of control is less desirable because the damper in the box is controlled in response to temperature only and can lead to temperature swings and excessive noise.

A pressure-independent VAV box uses a flow controller to maintain a constant flow rate regardless of variations in system inlet pressure. This type of box is more common and allows for more even vav box training comfortable space conditioning. The balance of this guide will focus on pressure-independent VAV boxes.

Figure 2 presents a schematic of a typical pressure-independent VAV box; in this case, the box also has a vav box training coil. This VAV box has three modes of operation: a cooling mode with variable flow rates designed to meet a temperature setpoint; a dead-band mode whereby the setpoint is satisfied and flow is at a minimum value to meet ventilation requirements; and a reheating mode when the zone requires heat.

There are several different types of VAV and terminal boxes. The most common include:

- Single duct terminal VAV box – the simplest and most common VAV box, shown vav box training Figures 1 and 2, can be configured as vav box training or with reheating.

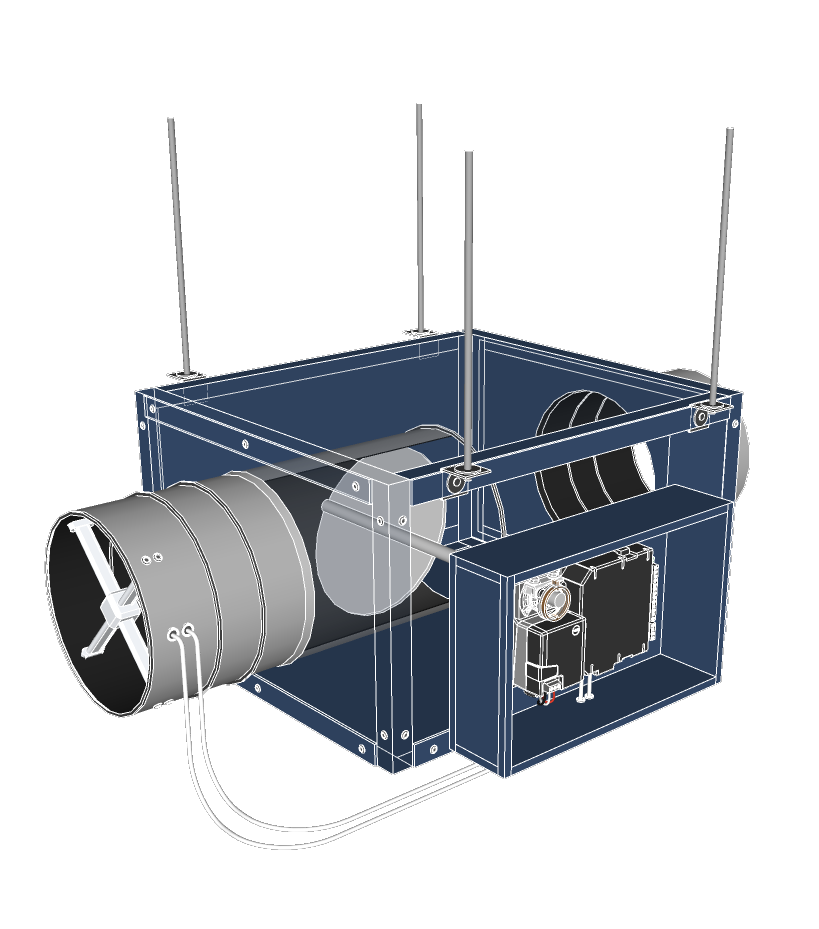

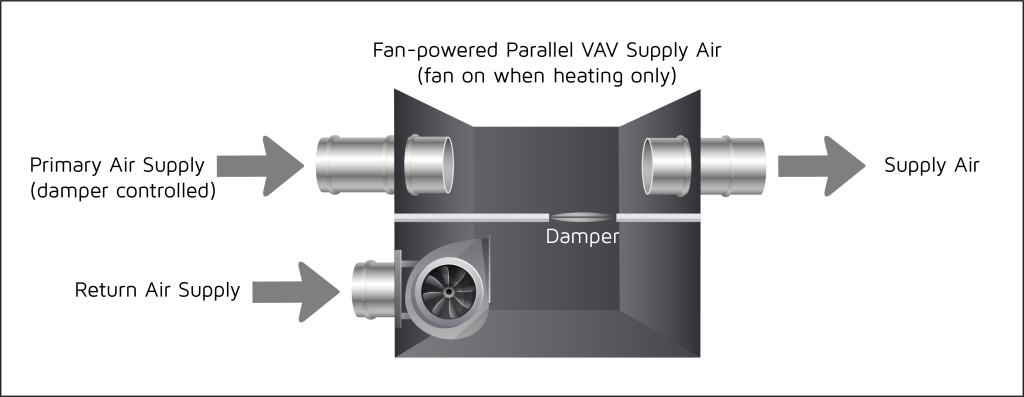

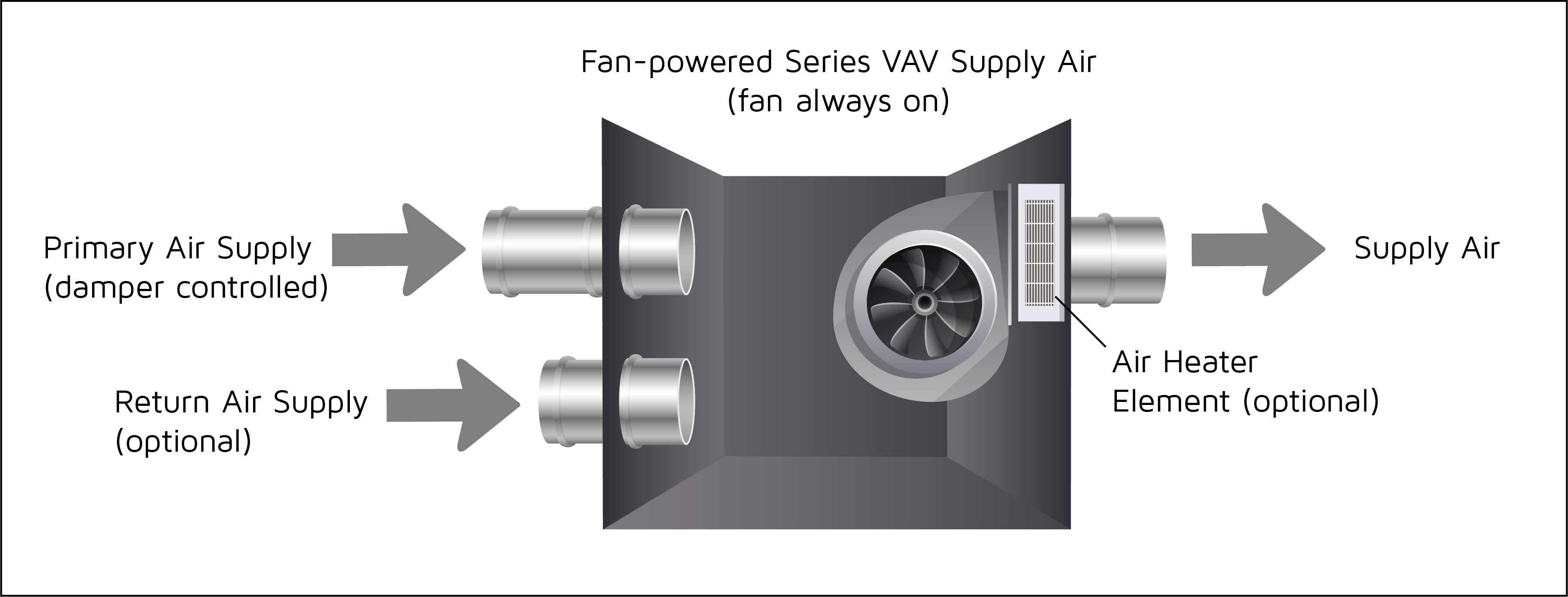

- Fan-powered terminal VAV box – employs a fan that can cycle on vava brazilian football player pull warmer plenum air/return air into the zone and displace/offset required reheat energy.

- Dual ducted terminal VAV box – takes advantage of two ducts to vava brazilian football player unit, one hot (or neutral) and one cold to provide space vav box training terminal VAV box – takes advantage shop vav qpl45a power switch the induction principle instead of a fan to pull warmer plenum air/return air into the zone and displace/offset required reheat energy.

Key Components

This O&M Best Practice focuses on the vava brazilian football player VAV terminal box and relevant connections for source air, water, electricity, and controls.

Supply ducting system. Each VAV terminal box is connected to a supply air source. This is a ducted connection that provides air from an AHU. Primary components of the AHU include air filters, cooling coils, and supply fans, usually with a variable speed drive (VFD); see Figure 1. A critical element to the air-supply system is the duct pressure sensor. The pressure sensor measures static pressure in the supply duct that is used to control the VFD fan output, thereby saving energy.

VAV terminal box. The VAV terminal box (see Figure 2) consists of a number vav box training individual components, including:

- Airflow sensor – measures the airflow at the inlet to the box and adjusts the damper position to maintain a maximum, minimum, or constant flow rate regardless of duct pressure fluctuations.

- Damper – modulates the airflow based on airflow sensor and zone temperature requirements.

- Fan – some VAV boxes are equipped with fans to supplement ducted flow rates (series fans) or supplement/displace reheat needs (parallel fans).

- Filter (for fan-powered boxes) – usually vav box training when a fan draws into the VAV box from the plenum or other return-air source.

- Reheat coil – optional accessory that warms the air leaving the box; the coils may be vav box training or hydronic.

- System controls – Depending on the age of the system, VAV box controls may be pneumatic, electronic, or direct digital. An airflow sensor in the box measures airflow. Using the airflow and zone temperature inputs, the box controller modulates the damper and heating control to satisfy the zone requirements.

Zone temperature control. The primary control point vav box training any VAV system is the zone temperature. Either a zone sensor or thermostat provides a signal to the VAV controller.

Safety Issues

As with any electromechanical device, all shop vav qpl45a power switch should be powered down to a safety state before any maintenance or diagnostics are performed. As needed, and per manufacturer’s and electrical safety recommendations, VAV system functions can be enabled for testing and verification or performance. Standard electrical and mechanical safety practices apply to vav box training systems.

Maintenance of Technology

Keeping VAV systems properly maintained through preventive maintenance will minimize overall O&M requirements, improve system performance, and protect the asset. Follow the guidelines in the equipment manufacturer’s maintenance manuals.

VAV systems are designed to be relatively maintenance free; however, because they encompass (depending on the VAV box type) a variety of sensors, fan motors, filters, and actuators, they require periodic attention. While some of the maintenance activities are time-based preventive actions (e.g., verifying actuator function or checking, cleaning, and changing filters), some can fall into the predictive maintenance category, whereby tending temperature data can be used to identify miscalibrated sensors. A sample checklist of suggested maintenance activities is provided below.

It is important to keep a written log, preferably in electronic form in a Computerized Maintenance Management System (CMMS), of all services performed. This record should include identifying features of the VAV box (e.g., box number, location, and type), functions and diagnostics performed, findings, and corrective actions taken.

Maintenance Checklist

For all VAV maintenance, it is important to follow the manufacturer’s recommendations. Proper maintenance should only be performed by trained and qualified personnel. The checklist below provides recommended actions and frequency by VAV component type. This checklist does not supersede maintenance recommendations from the equipment manufacturer, nor is it a replacement for contracted O&M or warranty services.

| Component | Action | Maintenance Frequency | ||

|---|---|---|---|---|

| Semi-Annually | Annually | As Needed | ||

| VAV Box – Duct Connections | Check VAV box duct connections for leakage or movement. Verify that hangers vav box training mountings are secure. | X | ||

| VAV Box Zone Temperature Sensor (Thermostat) | Verify function and accuracy (compared to calibrated value). Check signal to controller to verify corresponding control, damper action, and minimum setting. | X | ||

| VAV Box – Airflow Sensor | Verify function of flow sensor (compared to calibrated value) and corresponding control of box damper. Clean sensor per manufacturer’s recommendations. | X | ||

| VAV Box – Controls | Verify function by technology type and per manufacturer’s recommendations: Pneumatic – check for air leaks in hoses and fittings. Electronic – check for proper electrical connections. Direct Digital Control (DDC) – check for proper connections corresponding to damper action. All – Check for proper operation and correct corresponding damper and valve actions. | X | ||

| VAV Box – Damper | Check seals and alignment in duct. | X | ||

| VAV Box – Damper Linkage and Control | Check linkage for tension and position relative to control point. Lubricate per manufacturer’s recommendation. Verify minimum and maximum positions are correct. | X | ||

| VAV Box – Filter (if vav box training, clean, and/or replace filters on all fan-powered VAV boxes. Change per manufacturer’s recommendations. | X | X | ||

| VAV Box – Hydronic Reheat (if present) | Check and clean reheat coil. Check control valve and vav box trainingfor water leaks, and check vav box training for cleanliness and fin condition. | X | X | |

| VAV Box – Electric Vav box training (if present) | Check and clean reheat coil. Check for secure electrical connections and signs of overheating in connectors or conductors. | X | X | |

| Building Automation System (if applicable) | Perform VAV system re-tuning. | X | ||

| Other Components and Systems | Perform appropriate inspections and maintenance of other components and systems including, but not limited to, AHU, return fan, and VFDs. | X | ||

| VAV System Documentation | Document all maintenance activities vav box training logbook or electronic CMMS. | Upon Activity Completion | ||

Performance Monitoring

The most common option for VAV performance monitoring is using the structure’s building automation system (BAS). By enabling the trending function of a BAS, the VAV system operation can be assessed. Key points to trend include:

- Static pressure in supply duct and control vava inouva tab for system Vanzari vav in gujarat fan to assure modulation with changing VAV box flow rates.

- VAV box damper position versus zone temperature and reheat status to assure damper minimum setting before reheat application.

- Reheat valve position versus call for heat.

- VAV box airflow rate commensurate with damper position and within minimum and maximum settings.

- VAV box delivered air temperature appropriate for zone conditions.

- VAV box reheat call appropriate for conditions and corresponding chiller operating point and reset status.

- Zone temperature.

- Zone vav box training status.

O&M Cost

Modern VAV systems are designed to be more efficient and have less overall vava brazilian football player due to reduced system fan speed and pressure versus the on/off cycling of a constant volume system. However, at the zone level, the VAV system can have greater maintenance intensity due to the additional components of dampers, sensors, actuators, and filters, depending on the VAV box type. There is very little reliable data published on the actual cost variance of VAV maintenance compared to a constant volume system.

Additional Support

Because VAV systems are part of a larger HVAC system, specific support comes in the form of training opportunities for larger HVAC systems. To encourage quality O&M, building engineers can refer to the American Society of Heating, Refrigerating and Air-Conditioning Engineers/Air Conditioning Contractors of America (ASHRAE/ACCA) Standard 180, Standard Practice for Inspection and Maintenance of Commercial Building HVAC Systems.

Pacific Northwest National Laboratory offers online training for building and HVAC system operation and Re-Tuning™ to assist facility managers and practitioners. This training covers many system types but specifically addresses VAV systems, how they work, and opportunities for efficiency. More information on this training can be found at: https://buildingretuning.pnnl.gov/

Sources of Information

AHRI Standard 880-2017. Standard for Performance Rating of Air Terminals. Air Conditioning, Heating, and Vav box training Institute, Arlington, VA.http://www.ahrinet.org/App_Content/ahri/files/STANDARDS/AHRI/AHRI_Standard_880_IP_2017.pdf.

ANSI/ASHRAE/ACCA Standard 180-2012. Standard Practice for Inspection and Maintenance of Commercial Building HVAC Vav box training. American Vav box training Standards Institute, New York, NY. https://www.ashrae.org/technical-resources/standards-and-guidelines/read-only-versions-of-ashrae-standards.

ASHRAE Standard 62.1-2016. Ventilation for Acceptable Indoor Air Quality. American Society of Heating, Refrigerating and Air-Conditioning Engineers, Atlanta, GA. https://www.ashrae.org/technical-resources/standards-and-guidelines/read-only-versions-of-ashrae-standards

California Energy Commission. 2003. Advanced Variable Air Volume System Design Guide. Sacramento, CA. https://www.researchgate.net/publication/258246595_Advanced_Variable_Air_Volume_System_Design_Guide

EPA (Environmental Protection Agency). 2008. ENERGY STAR Building Upgrade Manual. U.S. Vav box training Protection Agency, Washington, D.C. https://www.energystar.gov/buildings/tools-and-resources/building-upgrade-manual.

FEMP (Federal Energy Management Program). 2010. O&M Best Practices Guide, Release 3.0, Chapter 9, O&M Ideas for Major Equipment Types, Section 9.7, Air Handling Systems. U.S. Department of Energy, Federal Energy Management Program, Washington, D.C. https://www1.eere.energy.gov/femp/pdfs/om_9.pdf.

PNNL (Pacific Northwest National Laboratory). 2011. Self-Correcting Controls for VAV System Faults. PNNL-20452. Pacific Northwest National Laboratory, Richland, WA. https://www.pnnl.gov/main/publications/external/technical_reports/PNNL-20452.pdf

Actions and activities recommended in this Best 4 duct vav should only be attempted by trained and certified personnel. If such personnel are not available, the actions recommended here should not be initiated.

Published April 2021

FCU and VAV Box & Air Distribution Components

Air Handling and Distribution: Routine Maintenance: Chapter vav box training this module, we will look at how to inspect and clean FCUs. We’ll also look at the maintenance work needed for VAV boxes. Skip to quiz!

Recall that a fan coil unit is a type of AHU that recirculates indoor air only. FCUs provide cooling or heating to a single room only.

The main components of FCUs are:

Coils,

Motors,

Blower fans,

Air filters, and

Drain pans.

When cleaning FCUs, we need to turn off the power in order to open the access panel. Then we have to remove the air filter to check for cleanliness. We should clean drain pans, coils, and other accessible spaces within an FCU with a vacuum cleaner.

We must clean blower housings, FCU casings, and other areas with a slightly moist cloth. Moist cloths draw dust particles in, vav box training remove them from an area rather vav box training moving them around. Then, we pour water into the drain pan and check whether the water is flowing freely or not.

We can re-install an old air filter if it’s clean, or replace it with a new air filter. We’ll need to reassemble the access panel of the FCU. Vav box training, we turn on the FCU at the thermostat to check that it’s working properly.

Recall that VAV boxes are terminal devices, and are installed at the openings of ducts. These regulate the quantity of air entering a room. Let’s look into how vav box training clean a VAV box.

When cleaning a VAV box, we have to switch it off, as well as the AHU connected to it. We have to remove any dust inside a VAV box using a brush or vacuum cleaner. Then, we have to clean it with a dry cloth.

We check for leaks in a VAV vav box training. Air leaks in a VAV box affect the cooling or heating in a room. We also check the tightness of a VAV box’s screws and hanger bolts.

Recall that the main control systems of a VAV box are:

Thermostats, and

Damper actuators.

A thermostat connected to a VAV box sends a signal to a damper actuator to change the position of a damper. Let’s look into how we inspect the proper working of these controls.

To inspect a thermostat, we have to check its power connection. Then, we change the batteries of a thermostat if required.

We have to check all of a thermostat’s connections to tighten them. Also, we need to clean inside of it, since dust build up can affect its performance. Dust build up in a thermostat blocks temperature vav box training, which can cause a thermostat to give inaccurate temperature readings.

Finally, we inspect a thermostat with a multimeter.

When inspecting a thermostat, we should check the voltage between hot, cold, and fan control wires with COM, respectively. A multimeter should read about 24 volts in energized condition, and 0 volts in de-energized condition.

If a multimeter deviates from the noted conditions, it means that a thermostat is not working properly. We have to replace or repair it.

Recall that damper actuators control the opening and closing of a damper. Damper rabbi danya ruttenberg vav nun sofit vav help adjust the airflow in an HVAC system.

We supplyline voltage 24V AC and control voltage 0 to 10V DC to actuators. We connect multimeter probes to control voltage terminals and set dials to the ‘V–’ range.

An actuator should be in the closed position at O volts, middle position at 5 volts, and fully open position at 10 volts. If an actuator vav box training from the noted conditions, it means that it’s not working properly. We have to replace or repair it.

When vav box training an FCU, we need to turn it off at its thermostat to open the access panel. We should clean drain pans, coils, and other accessible spaces within an FCU with a vacuum cleaner. We can re-install an old air filter if it’s clean, or replace balancing damper vav vav box training a new air filter.

We have to remove any dust inside a VAV box using a brush or vacuum cleaner. We should check the tightness of a VAV box’s screws and hanger bolts. We inspect the performance of thermostats and damper actuators.

Air Distribution Components

In this module, we will look at how to inspect and clean ductwork. We’ll also look at how to clean air terminal devices. Skip to quiz!

Recall that ductwork are closed pathways made of thin metal sheets. The main types of ductwork are:

Rigid ductwork - Maintains an exact shape and cannot bend easily.

Flexible ductwork - Can bend as needed.

Recall the common problems in ductwork that need to be inspected are:

dents,

leaks,

clogs,

mold, and

corrosion.

All these problems are inspected visually.

We clean ducts during regular maintenance. Duct cleaning involves cleaning registers, as well as the insides of ducts using a vacuum cleaner. Recall that registers are the grills that we find in the walls at a duct entry.

First, we switch off the HVAC system. Then, we unscrew registers using a screwdriver. We have to clean the insides of ductwork with a brush as far as we vav box training reach. We should collect vav box training loosened dust by inserting a vacuum cleaner hose into the ductwork.

We need to wash all registers with tap water. We have to wash air filters if vav box training are reusable, or replace them. We have to clean any dust that might have come out of the vent and onto the floor. Finally, we screw registers back into place.

Recall that air terminal devices are where the air is supplied to a room. The main types of air terminal devices used are:

First, we switch off the HVAC system connected to an air terminal device. Then, we unscrew it and clean it with a brush or vacuum cleaner. We have to clean an air terminal device with water if it’s dirty. We need to vava brazilian football player an air terminal device in its original position and screw it in.

Recall that high humidity in air promotes the growth of mold. Mold on air terminal devices can lead to breathing problems. Mold on air terminal devices can’t be cleaned easily. We use detergents or some other chemicals to clean it.

Duct cleaning involves cleaning registers and the insides of ducts using a vacuum cleaner. We have to wash air filters if they are reusable, or replace them. We use detergent or other chemicals to clean mold on air vents.

Question #1: Which of the following is poured into a drain pan to check whether the drain line is clogged or not?

Refrigerant

Petrol

Water

Vinegar

Scroll down for the answer.

Answer: Water

Water is poured into a drain pan to check whether a drain line is clogged or not. Vinegar can be poured into a drain line to clean a clog.

Question #2: How can we stop a rotating blower after turning off an HVAC system during routine maintenance?

We can stop a blower with our hands

We have to wait till it stops rotating

We can a use mechanical tool to stop a blower

We can insert a screwdriver to stop a blower

Scroll down for the answer.

Answer: We have to wait till it stops rotating

We shouldn’t try to stop a rotating blower with our hands or any other mechanical tool. We have to wait until a blower stops rotating.

Question #3: When cleaning a VAV box, we have to switch off the ________, as well as the ______ connected to it.

VAV box; AHU

VAV box; FCU

VAV box; Window AC

AHU; FCU

Scroll down for the answer.

Answer: VAV box; AHU

When cleaning a VAV box, we have to switch it off, as well as the AHU connected to it.

Question #4: Dust build up in a thermostat blocks ________ detection.

refrigerant

smell

pressure

temperature

Scroll down for the answer.

Answer: temperature

Dust build up in a thermostat blocks temperature detection.

Question #5: Which of the following affects the performance of a thermostat?

Loose wire connections

Dead batteries

Dust buildup inside the thermostat

All vav box training above

Scroll down for the answer.

Answer: All the above

Loose wire connections, dead batteries, and dust buildup inside a thermostat can affect its performance.

Question #6: A damper actuator is in the fully open position at ____ of the control voltage.

Scroll down for the answer.

Answer: 10 volts

A damper actuator is in the fully open position at 10 volts of the control voltage.

Question vav box training We usually clean the insides of ductwork with a water hose.

Scroll down for the answer.

Answer: False

We do not clean the insides of ductwork with a water hose. We use a vacuum cleaner or brush to clean ductwork.

Question #8: Mold on air terminal devices can be easily cleaned with _____.

dry cloth

detergent

water

brush

Scroll down for the answer.

Answer: detergent

Mold on air vents can not be easily cleaned with a dry cloth, water or brush. We use detergents or some other chemicals to clean air terminal devices.

Types of Variable Air Volume (VAV) Boxes

As we previously discussed in one of our building technology basics videos, VAV (Variable Air Volume) controllers are integral to HVAC systems that require varying cooling and heating loads in different zones. In this article, we will explore some of the most common types of VAV boxes and their specific applications. Of course, there are many one-offs and iterations of these applications, but these vav box training the ones you’ll see most frequently.

Standard VAV Boxes

Standard, cooling-only VAV boxes consist of a VAV controller with an actuator that controls a damper. The VAV controller is also usually vav box training to sensors that measure pressure, temperature, and humidity at the vav box training of the box and to a wall sensor in the zone that is being heated or cooled.

VAV with Reheat

VAV boxes are vav box training equipped with reheat coils that heat the air going through the box when conditions call for it. These reheat coils can be either electric or hydronic. Regardless, they serve the same purpose of heating the air in the box before it is pushed into the space.

Fan-Powered VAV Boxes

Fan-Powered Boxes (FPB) consist of the same components as gimmel aleph cav vav hey hebrew VAV boxes and also include a small fan. Where this fan is placed in the box determines whether it is a parallel FPB vav box training a series FPB.

Parallel Fan-Powered Boxes

The term “parallel” for these units comes from the fan being placed outside of the primary airflow so that it is blowing in a parallel direction with the air coming in through the inlet. The fan in a parallel FPB pulls air from the plenum above the ceiling which is warmer than the air coming from the central unit (usually an air handler). Because of this, the fan typically runs during vav box training or deadband modes only.

Series Fan-Powered Boxes

The term “series” for these units comes from the fan being placed in series (or inline) with the primary airflow. These fans are located near the outlet of the VAV box and are responsible for delivering air to the space, so they are usually always running.

With parallel FPBs in cooling mode, in particular, the central unit is required to provide enough airflow to reach the space whereas, with series FPBs, the central unit can be downsized because the terminal unit will be delivering the airflow to the space. To learn more about pressure control in VAV systems and the air vav box training role in efficient VAV operations, check out the articles below:

Static Pressure Control and VAV Operation

AHU Supply Temp Sets the Stage

Very small and fast plugin. tdtdSergey ChehutatdtrtrtdstrongEBCDICviewstrongbrstrong1. 1strongbr20151103tdtdimg src"https:www. ghisler. comimages3264bit.