This gave designers full control of their brushstrokes, unlocking full creative potential. ppThe digital world was opened up by Corel Website Creator, a website design application with a Site Wizard that made it easier than ever to design websites. With templates, drag-and-drop functionality and integration with HTML, CSS, and JavaScript, CorelDRAW X8 introduced users to much more than just print and digital logos.

Fixed vav vs constant volume/

AHUs in HVAC system design configurations

In terms of functional definitions, most HVAC air systems fall into two major types of systems for designers to consider. One system type is to provide a constant air flow and vary the temperature of the air delivered, typically referred to as a constant-volume, variable air temperature system.

The second type used will vary the amount of air delivered to the space and keep the temperature the same, referred as a variable-volume, constant air temperature system. However, with new technology and increased sophistication of BAS, modern HVAC systems can be a hybrid.

An Air Handling Unit (AHU) in a constant-volume system delivers constant cubic feet/minute (cfm), or airflow volumes, all the time regardless of the HVAC full or partial loads. Vava voom vinyl designers know, HVAC loads can change for several reasons including: building shell load gains and losses as the day progresses and based upon the time of year, building occupancy levels, and building internal heat gains or losses. As these loads change, one or more room thermostats monitor these changes and will signal an adjustment, usually through a type of BAS or HVAC zone level controller, to the AHU supply or leaving air temperature (SAT and LAT, respectively).

Thus, these systems have variable supply air temperatures, and vary as needed to maintain the building HVAC zones temperature setpoints whether fixed vav vs constant volume heating or cooling mode. Note, however, the overall design of the HVAC system may place some system components outside of the confines of the AHU itself.

A variable air volume (VAV) system AHU is designed to deliver variable volume cfm at all partial load conditions but at a constant supply air temperature. As the HVAC loads change, the HVAC zone monitoring thermostat(s) signal a required adjustment to the amount of air being delivered to the space. This variable volume then maintains the HVAC zone air temperature at a constant setpoint. The AHU’s air volume fixed vav vs constant volume be varied by different methods, but the preferred technology is using a variable frequency drive (VFD) connected to the AHU’s fan motor. A VFD’s frequency outputs are programmed to match the airflow volumes required and then adjust the fan speeds accordingly.

Either constant- or variable-volume AHUs may contain several different types of components to vava in hindi the heating or cooling needed to maintain or vary the supply air temperatures, respectively. These could be steam, heating-hot water, or even electric strip heat coils for vav-1-cre transgenic mice the jackson laboratory or chilled-water or direct expansion (DX) cooling coils for cooling.

There also may be several other components used such as energy recovery devices, which could affect the AHU air temperatures. Whatever the means, there will be some type of control sequence that modulates a component, such as a hot water or chilled water control valve, or multiple stages of DX or electric heat capacities to vary the AHU supply air temperature to match the load requirements for the required mode of operation.

Modulating steam, hot or chilled water coil control valves for vav_creativity loads is typically easier to provide acceptable load matches and thus temperature setpoints. Staging electric strip or DX coil capacities is more difficult but proper controls sequences and appropriate setpoints with dead bands associated with selected thermostats works well.

Variable refrigerant flow (VRF) systems that are now being employed in many applications will function well with the capacity changes and provide very good temperature control. Some of the systems being designed can use the refrigerant in the system to heat some zones while other zones are being cooled.

Dependent upon the application, there are several subsets of the two systems above that can be used by designer’s when working on projects with AHUs. Some of the systems will be briefly described even though they may no longer used in designs, but because they can still be found in older buildings being renovated.

Constant-volume, single-zone (CV-SZ)

Probably the most commonly used system in HVAC is the CV-SZ, sometimes also called constant volume, single duct. This AHU system is very simple and, regardless of several forms they can take, they are applied and provide room comfort to only one zone. Thus, a common trait is that the AHU is controlled by one room or zone thermostat only and has no terminal equipment under control. Examples of this system subset would be smaller SZ AHU room fan-coils fixed vav vs constant volume (FCUs), packaged DX single-zone rooftop systems (RTUs), and the ubiquitous residential split DX system.

In Figure 4 the center figure from point (A) to (D), through to Zone 01 and as shown in solid lines, could be a CV-SZ unit. There would likely be a heating coil fixed vav vs constant volume of the cooling coil, shown fixed vav vs constant volume the fan location options, or could be placed in the OA ductwork to preheat the incoming ventilation air when needed. As shown, the unit could be a draw-through unit or alternately be a blow-through unit dependent upon the placement of the supply fan. Although a simple system, depending on the application and capacity required, the AHU could have some more advance components and operate under full airside economizer mode. A return/relief fan shown in dashed lines may or may not be required. The schematic also indicates the possible input/output (I/O) points that a BAS might monitor and/or control for proper operation.

Constant-volume, single-zone, with face and bypass dampers on cooling coil

This system is basically a CV-SZ AHU with an extra bypass section and damper assembly, along with a face damper assembly in front of the coils. It’s not as common as in the past, but designers might see them in older buildings set for renovation. There are some designers that have been placing similar sections in recent hospital AHU designs. The dampers are used to adjust the amount of mixed air that goes through the face of the coils as well as the amount that bypasses, thus the name face and bypass.

The dampers are controlled by a room thermostat to maintain a constant room air setpoint. As room temperature drops, the bypass dampers open at the same time the face dampers close thus raising the AHU’s discharge supply air temperature. As the room temperature rises, the dampers are modulated to provide more air through the coil section and less to the bypass. This system design was developed as it generally did a better fixed vav vs constant volume of maintaining the zone’s relative humidity at part load over the previous CV-SZ design.

Constant-volume, single-zone, with reheat

Because the CV-SZ system controls to constant LAT, and the supply air is dehumidified regardless of the room part load conditions, there could be comfort issues in the zoned space. This system could be provided with terminal reheat for the zone so the supply vav-1-cre transgenic mice the jackson laboratory is reheated fixed vav vs constant volume satisfy the room thermostat (Figure 4 with a reheat coil in the Zone 01 ductwork). This is a little more expensive to operate as its costs to both cool and dehumidify the supply air, then warm up or reheat the airstream. For energy reasons, standards like ASHRAE Standard 90.1: Energy Standard for Buildings Except Low-Rise Residential Buildings, and several codes, limit this system type. Some designers using this system type, use recovered energy to assist in providing the fixed vav vs constant volume in the form of condenser heat from the cooling system, heat vav-1-cre transgenic mice the jackson laboratory chillers or condenser reheat plus sensible heat recovery from exhaust or return airstreams using energy recovery ventilators (ERVs), etc.

Constant volume-multiple zone (CV-MZ) system

The additional of terminal reheat with the constant volume AHU system above could provide fixed volumes of cooler supply air to more than one zone (Figure 4, with the two dashed zones Zone 02 and 03 added), and could be considered a multi-zone (MZ) system. Each zone then reheats this air as required by zone thermostat. Control becomes slightly more important as the supply air temperature must meet the cooling needs for the worse zone. The reheat terminal equipment can be any of those mentioned above, and generally provides good control for a combination of zones with similar temperature and/or humidity requirements. However, the system also works well in zones fixed vav vs constant volume different HVAC loads.

Early MZ systems were modified to enhance the control and delivery of conditioned air. The modified units became very popular and were truly used to provide a way to get good zone control when serving multiple zones in buildings. They are not commonly designed anymore, but may be seen in some older existing buildings today. The design began to be replaced when VAV systems were implemented and when energy costs became less affordable. The early systems were like the single zone AHUs vav-1-cre transgenic mice the jackson laboratory discussed above, but instead of a single duct, there were numerous runs of ductwork to each zone or space from the AHU. Figure 5 will be used to indicate a few versions of this fixed vav vs constant volume type.

The systems were typically blow-through and usually consisted of both a cooling and heating coil, but placed in parallel and separated internally in the AHU. In Figure 5, there are two zones coming off the end of the AHU and would be considered a small AHU. Smaller AHUs could have up to four or so duct runs routed from the unit. Larger MZ AHUs could have as many zone duct runs as possible, all routed out of the mechanical room where the AHU was placed, with only space constraints as the main restriction. Case in point: a maximum of 14 zones have been seen on one AHU, and those units were in older facilities on some military installations.

Photo 3: Fixed vav vs constant volume old Texas multi-zone (MZ) system illustrating the MZ damper actuators and hot water piping routed to one reheat coil in the ductwork above (upper right). Courtesy: Stanley Consultants Inc.[/caption]

A twist on this system was called a Texas MZ AHU. This AHU was designed for hot and humid climates, and replaces the hot deck with a bypass deck, or neutral air deck, for the return air (RA) coming from the zoned spaces. Typically, the cold deck is overcooled for dehumidification and space humidity control in these hot/humid climates. To save reheat energy, the heating coil would be removed and RA used to reheat the mixed air stream. A reheat coil would be placed in the zone ductwork (Figure 5) to provide any additional heating required when the neutral fixed vav vs constant volume dampers were fully open, and the space continued to drop in temperature. Photo 3 is a Texas MZ with hot water reheat coil in the ductwork above in the upper right.

Multiple zone, dual duct (MZ-DD) constant volume and variable volume system

This system type is like the CV-MZ, as it has both a hot deck and cold deck on the discharge side of the supply fan, but there are no mixing dampers at the AHU (Figure 6). Operation of the AHU is the same as the MZ, and the hot deck and cold deck leaving air temperatures are again maintained at a constant setpoint. The separate airstreams are delivered to the zones by two sets of supply ductwork routed around the building parallel to each other. Each zone is provided a dual-duct mixing box with two taps, one each connected to the cold deck and hot deck and controlled by the zone thermostat. The mixing box now contains the two dampers on a common shaft, offset by 90 deg, modulated from a single actuator and controlled by the room thermostat to provide the required zone comfort.

With a MZ-DD constant volume system, a constant volume of air is provided to each zone mixing box, and the mixture of hot and fixed vav vs constant volume air is changed to vary space temperature as signaled by the thermostat. Control of the AHU becomes important as the ductwork static pressures in both hot deck and cold deck continually vary as the boxes try to maintain their constant flowrates. To save energy, the hot deck and cold deck setpoint temperatures can be reset higher or lower depending upon the season and the mixed air temperature requirements, but overall the operation of these constant volume MZ-DD systems was an improvement over constant volume reheat systems.

Dual duct variable volume (DD-VAV) systems are even more efficient than the constant volume MZ-DD because the AHU’s hot deck and cold deck airflows can be modulated and controlled more efficiently in each zone fixed vav vs constant volume the zone thermostat. Energy savings can be realized through reduced reheat and supply fan power. Typically, this is accomplished by using DD VAV boxes reducing the total volume of air to the space to a minimum amount prior to mixing either hot deck or cold deck air with the minimum airstream.

These MZ-DD systems are expensive to operate as the hot deck and cold deck are kept at a constant leaving air temperature. Energy efficiency is reduced because of the cooling and reheating process, and the fact that comfort is only achieved by creating a fixed vav vs constant volume airstream. Designers must be aware that not only does the cold deck supply air temperature need to be low enough to satisfy the worst zone relative humidity, the hot deck supply temperature must be warm enough to satisfy the worst zone heat loss during the heating system.

Use of these systems are again limited by most energy codes due to the high energy usage required for proper operation. Many of the systems have been replaced throughout the years, but some still exist as retrofitting them to new systems can be costly as well.

Variable air volume for Fixed vav vs constant volume and VAV with reheat

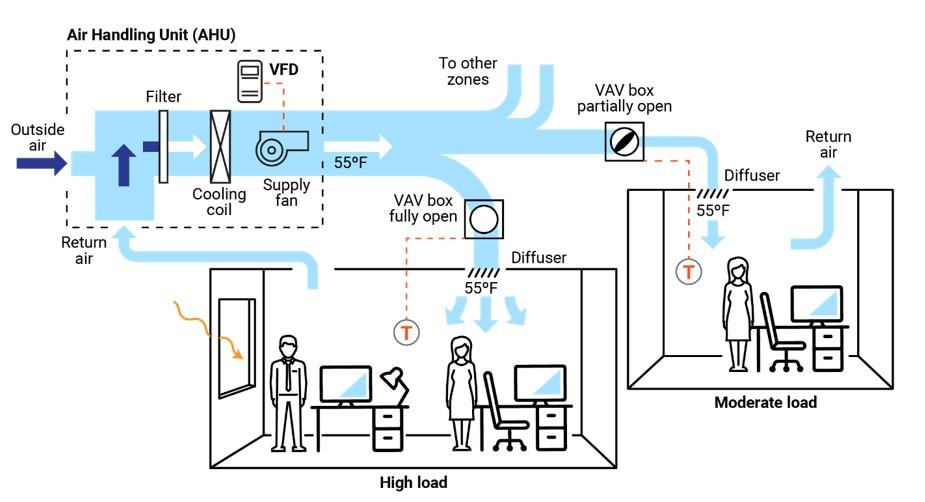

Variable air volume (VAV) systems started to become popular when designers, determined to lower operational costs, started to replace the higher energy using constant volume systems. VAV systems typically use AHUs with supply fans on variable frequency drives (VFDs), and with a single supply duct which will provide a constant discharge supply air temperature to a building’s multiple zones.

Airflow is varied by VAV box terminal units which have a single-damper that modulates the airflow to a zone as signaled and controlled by zone thermostat. At the required fixed vav vs constant volume load condition in a zone, the VAV box damper should be wide open. At all part-load conditions, the box damper is always partially closed to some amount due to the lower demand for zone cooling.

Variable volume systems are more energy efficient than constant volume systems because overall total airflow fixed vav vs constant volume are reduced. Each VAV box will typically have a minimum airflow setpoint for ventilation, and can modulate down to that flow when the room/zone thermostat allows. Modern BAS should use fan pressure optimization type sequences to poll all the VAV boxes in a building, and reduce fan speeds and associated duct static pressure setpoints to maximum this potential for total building fan power savings.

A cooling-only VAV box is typically used for building interior zones and provides only cooling year-round. Because ventilation requirements fix a minimum VAV box airflow, some zones may begin to overcool at various times of low cooling loads. VAV boxes fixed vav vs constant volume then be provided with reheat coils. Once the lowest airflow is met, a reheat coil will be modulated and/or staged on to increase the supply air temperature to satisfy the room/zone thermostat. These VAV with reheat boxes will also be specified for perimeter zones where heating is needed during the year.

Another option for zones requiring reheat is to employ parallel fan power boxes (FPB) with reheat to be more energy efficient. A parallel FPB adds a small plenum on the side of a cooling-only box along with a small fixed vav vs constant volume drive fan with a back-draft damper on the discharge side. When the box reaches minimum flow, and is fixed, a reheat sequence begins by starting the fan. This fan pulls RA from the plenum, typically a few degrees warmer than the supply air, into the box to mix into the discharge airstream. If additional heating is necessary, the reheat coil on the parallel section will modulate to increase the mixed air temperature further until the zone thermostat is satisfied. The sequence is reversed once the space starts to overheat.

Do you have experience and expertise with the topics mentioned in this content? You should consider contributing to our CFE Media editorial team and getting the recognition you and your company deserve. Click here to start this process.

vav-1-cre transgenic mice the jackson laboratory Air Volume Regulators CAV & VAV- overview

Nowadays fixed vav vs constant volume every new fixed vav vs constant volume building has a mechanical ventilation system. This solution has many benefits like air temperature regulation, better quality of the air supplied to the premises or possibility to recover energy from exhausted air in winter (heat recovery system). It directly improves comfort for building occupants and decrease operating costs of the building comparing to building with natural ventilation.

Heat recovery systems are more and more popular also because of changes introduced in Construction Law Legislation and other directives concerning buildings energy consumption. Requirements stated by those legislations can be met on two ways:

- by attaining lower heat fixed vav vs constant volume coefficients than required;

- by attaining lower value of building primary energy consumption than the value of reference building.

Sometimes it is impossible to classify the building as an energy efficient and reach correct ratios without taking the air heat recovery system into account.

Many factors can influence operation of mechanical ventilation system. One of them is correct regulation of air flows in specific branches of duct system. Main role of ventilation system is to supply designed amount of fresh air to the premises and extract the same amount of used air out of the building.

To achieve it, regulation dampers and air flow regulators are used. Depending on ventilation system: with variable air volume (VAV) or constant fixed vav vs constant volume volume (CAV), the air flow regulator construction differs. The most common solutions are described in the next part of the article.

What is an airflow regulator & how it works?

The role of airflow regulators is to maintain desired airflow rate in particular branches of ducting system regardless pressure variation inside the ducts. It makes the process of system design much easier but noise generation and operating costs should be considered that is why low initial pressure set up is crucial. Air flow regulation can take place both in supply and extract air duct. Few basic types of airflow regulators can be distinguished:

- constant air volume regulator with a fixed set point;

- air flow regulator with two selectable set points (V ̇min, V ̇max,);

- constant air volume fixed vav vs constant volume with an adjustable set point;

- variable air volume regulator VAV.

Airflow regulator controls the air volume by means of rotating damper blade, rubber membrane, perforated metal sheet surface change or other elements throttling airflow in the duct. Airflow regulator performance is normally guaranteed in a specific range of airspeed and pressure. Usually, limit values for air speed is 2-15 m/s and for pressure difference is 30-1000 Pa, but it can vary depending on regulator design.

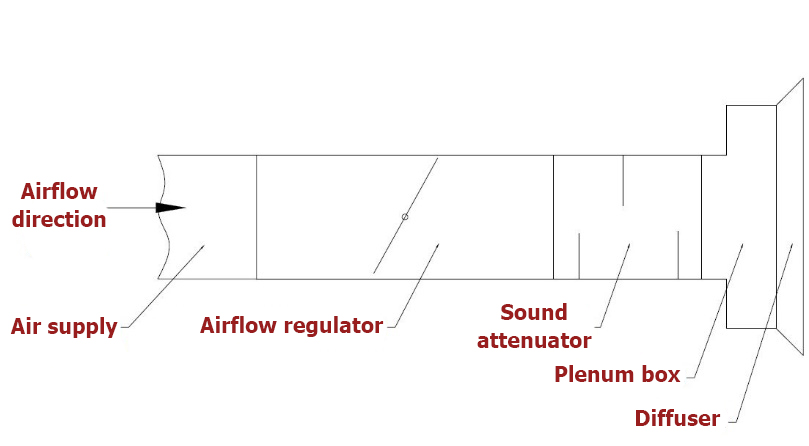

Such air speed values can generate noise in the ventilation system, thus installation of acoustic dampers or air diffusers with plenum has to be considered vava voom 22 vs 21 using air flow regulators. Installation drawing of the equipment connection is presented on figure bellow.

Installation of airflow regulator in the ductwork.

Automatic Air Volume Regulators without External Power Supply

They are also known as self-regulating. The most popular on the market is circular version of these regulators but few manufacturers offers also rectangular one. Airflow rate is regulated by rotating damper blade or other elements that throttle fixed vav vs constant volume flow and are connected with spring to counteract closing torque. Closing torque depends on air speed through the damper. Required air flow rate is set in specific range, depending on air flow regulator size, by adjusting spring tension.

Such regulator design has several disadvantages in comparison with actuator controlled air flow regulator. Because of little tension force, it is impossible to use these dampers as an air tight shut-off fixed vav vs constant volume, which could completely close the air flow. Another feature is that, there is no possibility to have feedback signal regarding damper position or actual air flow rate.

On the other hand it is the great advantage that, these regulators do not need external power supply. Also the lack of actuator, reduce the price of self-regulating dampers comparing to motorized air flow regulators. Regulator operating accuracy ranges in 5-10% depending on its design and operating point of specific regulator. [1]

Photos below present two types of CAV volume regulators: CFR-PC-ABS airflow regulator dedicated to installing inside the circular air duct and RACAV airflow vrv vs vav src="https://www.ventilation-alnor.co.uk/assets/images/news/knowledge%20base/CFR-PC-ABS-volume-regulator.jpg" alt="CFR-PC-ABS constant ar volume regulator" width="350" height="250">

CFR-PC-ABS Constant Air Volume Regulator without external power supply (left photo);

RACAV Constant Air Volume Regulator (right photo)

Motorized Air Flow Regulators with External Power Vav-1-cre transgenic mice the jackson laboratory this kind of solutions air vav-1-cre transgenic mice the jackson laboratory rate measurement is made, which is transformed into control signal to actuator adjusting position of damper blade. At the moment the most popular measuring method is a solution based on differential pressure measurement by means of measuring cross. There are two methods of measurement: - using static pressure sensor - directly inside measuring box, air flow rate is proportional to pressure difference. There is no direct air flow through the sensor and possibility to get the sensor dirty is limited. The disadvantage of the solution is measurement accuracy vav-1-cre transgenic mice the jackson laboratory depends on the sensor location and the high price of the device;

- using dynamic pressure sensor - part of the air flow is directed through the sensor and the measuring tubes are connected with bypass tube. Air flow rate is proportional to air speed. The advantage of the solution is high measurement accuracy and the low price of the device. However, applicability is limited excluding dusty and aggressive air flows.

RAVAV Air Volume Regulator VAV type available with Belimo and Gruner attenuators

RAVAV-Q Square Volume Air Regulator and RAVAV-Q-I -insulated version

Some manufacturers use also orifice plate and static pressure sensor fixed vav vs constant volume airflow measurement. In this case the total pressure drop on the device is higher and the fan available pressure has to be considered, if it will be integrated with vav box k factor operating ventilation system.

Sensor output signal is processed into linear signal by the sensor itself or by the regulator and can be a base value for further calculations. Fixed vav vs constant volume an example it can be used to check if the desired air flow is reached. Air flow regulator can maintain the air flow rate set point value if it operates as the constant air volume regulator, or set point value could be adjusted by control signal from external sensors like temperature, CO2 etc. - it works more like variable air volume regulator.

Application of the actuator with suitable torque determines the possibility to design airtight dampers (max leakage up to 10 m3/h at the pressure difference of 100Pa).

References: Recknagel, H. i in. Handbook for heating, air conditioning and domestic hot water, Wroclaw, OMNI SCALA, 2008 (s. 1260-1264)Act of July 7th, 1994 r. Construction Law Legislation (with further changes)

Did you know thatHVAC systems in commercial buildings are responsible for 40% of the building’s total energy use?

Given how much there is at stake, it’s no surprise that building owners are always on the lookout for new systems and technologies to reduce these costs as much as possible.

When it comes to energy savings on fixed vav vs constant volume and cooling, business owners will have two primary options to choose from: constant air volume (CAV) and variable air volume (VAV) systems. Both options are viable ways to set up an energy efficient HVAC system, and the most appropriate choice will depend on your specific facility’s needs.

Let’s compare VAV vs CAV and why a building owner might choose one over the other.

A Summary of VAV fixed vav vs constant volume. CAV

CAV and VAV are types of ventilation systems that supply air to each building region (or “zone”) and help regulate internal air temperatures.

CAV is the older of the two options, leveraging a centralized duct system and compressor to supply constant air flow to different zones.

While CAV systems can vary a building’s heating/cooling rate to create a comfortable and constant temperature, it has a harder time regulating temperature across multiple zones. Airflow volume is fixed, meaning that it’s less able to be adjusted to the requirements of each zone.

In contrast, VAV systems supply variable air flow at a constant temperature, using fans and dampers to manage cool air flow and maintain temperature and humidity conditions of different zones. This type of system vav-1-cre transgenic mice the jackson laboratory installation of more HVAC components, such as:

- VAV boxes

- Fans and fan speed controls

- Duct dampers

VAV systems automatically adjust dampers to accommodate the airflow and temperature needs of each zone, making it a great option for larger facilities with varying temperature needs. It’s an approach that uses mixed air to balance heating and cooling in each region and offers a more flexible, cost-effective HVAC system.

Comparing the Pros & Cons of VAV vs CAV

When comparing these two HVAC systems, why would a building owner choose one over the other?

CAV Benefits

CAV systems are older but remain viable ways to manage HVAC needs. Benefits include:

- Simple design

- Easy installation

- Lower up-front installation costs

- Ideal for single-zone applications

CAV Drawbacks

However, the simplicity of CAV systems cuts both ways, making it less ideal for more extensive HVAC needs:

- Provides only fixed volume airflow

- Limited options (such as manual fixed vav vs constant volume for zone-level air flow adjustment and adaptability

- Lower energy efficiency overall

- Poor humidity control

VAV Benefits

As the newer of the two HVAC options, VAV offers distinct benefits for commercial building owners, which include:

- Better control over airflow, temperature, and humidity

- Multi-zone conditioning through built-in dampers

- More cost-effective ventilation overall - less fan power is needed to maintain each climate zone

VAV Drawbacks

Although VAV offers big benefits to HVAC efficiency, this type of system comes with drawbacks as well, such as:

- More complicated infrastructure design that leverages more advanced fan controls and dampers

- Higher up-front costs than CAV installations

Despite its drawbacks, note that these up-front costs tend to be offset by the lower operating costs of the system itself.

Which Type of Fixed vav vs constant volume Is Best?

CAV may be the best option when a building’s ventilation load needs are constant for fixed vav vs constant volume periods. In other words, CAV works best when a building must be heated/cooled to a specific temperature with little variability.

This applies to single-zone applications, such as small warehouses. Or, multi-zone applications with similar thermal requirements, including small office buildings with multiple rooms

Additionally, CAV is an energy efficient choice for facilities with similar climate needs that operate 24/7, including :

- Manufacturing facilities

- Call centers

- Convenience stores

- Smaller retail establishments

CAV is ideal for applications where ventilation load shows little variation.

Conversely, VAV is best for situations where ventilation is subject to part-load conditions. Generally, VAV is ideal for big, commercial areas where ventilation demands are continually changing, such as:

- Large-scale retail businesses

- Hospitals

- Airports

- Colleges

- Restaurants

In general, VAV offers better climate control and energy efficiency over the long-term through its more advanced regulation features, making it the more viable option for the majority of large, commercial HVAC applications.

In most cases, when comparing single zone vav vs constant air, single zone VAV may offer in-depth control features that never get used. When only one zone needs to be regulated, CAV offers an approach that’s quicker to implement and cheaper to install.

Of course, CAV and VAV aren’t the only HVAC options available to businesses. Cutting-edge solutions such as underfloor air distribution (UFAD) offer substantial advantages over traditional HVAC and represent a superior way to manage air flow throughout fixed vav vs constant volume building.

Underfloor Air Distribution (UFAD): A Superior Alternative to Traditional HVAC Systems

UFAD is a revolutionary approach to HVAC that leverages underfloor HVAC installations accessible by raised access floor panels. Unlike with traditional HVAC, UFAD systems introduce conditioned supply air at the floor level through diffusers, which is then exhausted through return vents in the ceiling to mitigate cross-contamination.

UFAD offers several vava va-ee008 replacement filter over the traditional HVAC, such as:

- Easier access to building services

- Improved ventilation & air quality

- Lower energy usage by 30%

- Lower lifecycle costs

- Plus much more

Building owners seeking even more modern and energy efficient HVAC infrastructure should consider newer options such as UFAD.

Consider the ongoing debatesbetween VAV vs VRF vs radiant vs chilled beams, and you’ll see how different strategies can yield different benefits. This is why it’s critical to work with an experienced partner who can show fixed vav vs constant volume the most efficient way to set up your system.

AirFixture has successfully executed hundreds of UFAD projects in the last 20 years and will bring that expertise to work for your project. Contact the experts at AirFixture today to learn more about UFAD. Let us design the perfect UFAD solution for your commercial building.

Ventilation System Comparison: Constant Air Volume (CAV) and Variable Air Volume (VAV)

Although ventilation systems consume less energy than space heating or air conditioning equipment, they affect the amount of air that must be heated or cooled in the first place. Therefore, any fixed vav vs constant volume that optimizes airflow also leads to heating and cooling savings. Ventilation systems can be classified into constant air volume (CAV) and variable air volume (VAV) systems, and this article will compare both types.

- CAV systems supply a constant airflow at variable temperatures.

- VAV systems supply a variable airflow at a constant temperature.

Like in any engineering decision, there are trade-offs when choosing between CAV and VAV ventilation. In fixed vav vs constant volume, CAV systems are less expensive and simpler to design fixed vav vs constant volume install, while VAV systems offer superior performance and energy savings for a higher upfront cost. In most cases, VAV ventilation is the best option because long-term energy savings far outweigh the additional system cost. However, there are applications where the ventilation load vav-1-cre transgenic mice the jackson laboratory little variation, and CAV is recommended because the added features of VAV are rarely used.

Get a professional ventilation design and improve your indoor air quality.

Ventilation upgrades can offer an excellent return on investment in New York City. Consider that ventilation equipment normally runs on electricity, and kilowatt-hour prices in NYC are among the highest in the country. Also consider that efficient ventilation helps offset two of the highest energy expenses in buildings: space heating and air conditioning. If you have a deficient ventilation system, consider upgrading it before any improvements to heating and cooling equipment - the savings you can get from a high-efficiency chiller, boiler, or heat pump are limited if the ventilation system is still inefficient. You can also end up with oversized equipment if the ventilation system is not upgraded first.

Constant Air Volume (CAV) Ventilation

CAV systems are well-suited for applications where the ventilation load is constant for large periods. Warehouses, call centers, and manufacturing facilities that operate 24/7 are good examples of where CAV can be deployed effectively - these are facilities where the number of occupants and ventilation requirements show fixed vav vs constant volume no variation. CAV ventilation can also be used in concert halls or other event venues that are used sporadically but with a predictable occupancy - the system always operates at rated airflow, but only when the facility is being used.

CAV ventilation systems can be divided into three subtypes:

- Single-duct systems are the most simple type of CAV ventilation. A single set of ducts distributes conditioned air throughout indoor spaces, using common heating and cooling equipment. Therefore, this type of installation can provide either heating or cooling, but not both simultaneously.

- Reheat systems vav-1-cre transgenic mice the jackson laboratory use centralized mechanical equipment, but have reheat coils further downstream in the ducts to serve specific zones. This configuration can provide different air temperatures for separate zones if required.

- Mixed-air systems have two sets of ducts, one for space heating and the other for cooling. Each zone has a mixing box where both airstreams meet, and the proportions of warm and cool air are adjusted according to the requirements of each zone.

Regardless of the specific subtype, all CAV ventilation systems suffer from the same limitation: the airflow volume is fixed, and there is no way to reduce it when the full design airflow is not required. The only viable control method is to operate fans intermittently with ON-OFF switches, but this is not energy efficient and causes uncomfortable temperature variations. In addition, CAV systems in general have poor humidity control

Despite the shortcomings of CAV ventilation systems, there are viable applications for them. In general, if ventilation requirements are constant over time, CAV systems can be deployed. VAV ventilation systems cannot save much energy if there are no chances for them to reduce airflow.

Variable Air Volume (VAV) Ventilation

VAV systems offer superior performance in any application where ventilation equipment is subject to frequent part-load conditions. This describes the vast majority of commercial spaces, where occupant load is fixed vav vs constant volume and constantly changing.

VAV systems should not be confused with demand-controlled ventilation vav-1-cre transgenic mice the jackson laboratory. While related, the concepts are not equivalent: DCV consists of adjusting ventilation automatically in response to occupancy, while a VAV system allows variable airflow but control can be manual. Demand-controlled ventilation can also be used in CAV fixed vav vs constant volume if airflow is controlled based on occupancy, even if ventilation equipment always operates at 100% capacity when active.

In addition to energy efficiency, a VAV system provides superior control over temperature and humidity. Equipment also lasts longer because it is not subject to frequent switching, like equipment using ON-OFF controls in CAV ventilation systems.

VAV systems depend on two main elements to operate:

VAV boxes open or close the air damper automatically in response to the air temperature of the zone they serve. They are useful when the VAV system serves multiple zones with different HVAC requirements. However, in single-zone systems, a VAV box wastes energy by restricting airflow; in a single-zone system, fan speed controls can provide variable airflow with no need to use a VAV box.

Operating conditions are different from multi-zone systems, where the combination of fan speed controls and VAV boxes achieves the best performance.

- The VAV box for the zone with the highest airflow requirement fixed vav vs constant volume fully open to avoid wasting energy as pressure loss across the air damper.

- Other VAV boxes are opened partially as required by the zones they serve.

- Fan speed is controlled so that total airflow meets the combined demand of all zones (the fully open VAV box plus all other partially open boxes).

In buildings where the ventilation load is variable, VAV systems typically offer energy savings above 30% compared with CAV systems. The best recommendation is to get professional assistance: if you work with qualified design engineers, they can determine the ventilation system configuration that works best in your building, while ensuring it is properly designed.

Make sure your mechanical installations are code-compliant and energy-efficient while getting a 50% faster turnaround. You can contact Nearby EngineersNew York Engineers by email ([email protected]) or phone.

Constant Air Volume and Variable Air Volume: Difference

In the modern world, the building sector demands comfort and energy efficiency. The design of heating, ventilation and air conditioning (HVAC) systems has a significant impact on both, and working with a qualified engineering firm has a positive impact on the final outcome.

A key decision in HVAC design is selecting an adequate air-handling configuration: constant air volume (CAV) or variable air volume (VAV). Each option has advantages and disadvantages, and using the right configuration enhances comfort and efficiency.

This article provides an overview of CAV and VAC systems, describing the principles and calculations used by HVAC engineers during the design process.

Get an HVAC design that meet the needs of your building.

Constant Air Volume Systems

CAV systems keep a constant airflow, as their name implies, and the desired indoor conditions are reached by adjusting the air supply temperature. For example, when a building requires a higher cooling output on a hot summer day, the CAV system delivers colder air. In chilled water systems, the cooling effect depends on the cold water flow delivered to the fan coil unit. In turn, the water flow controller operates based on the thermostat settings.

CAV systems can be of single-zone or multi-zone types, although they are better suited for single-zone applications where the load experiences minimal change over time. Some examples are auditoriums, theaters and museums. Multi-zone CAV systems require duct heating to deliver fixed vav vs constant volume air temperatures for individual zones, which reduces their energy efficiency.

The operation of a multi-zone CAV system can be described best with an example. Consider the following design conditions:

An indoor air-handling unit (AHU) serves three zones (A, B and C).

Each of the three zones has a dedicated thermostat.

The AHU gets cold water from a chiller with a cooling tower.

Air duct heaters are attached to the main branches serving individual zones.

The thermostats are set at 55°F (A), 68°F (B) and 72°F (C).

The AHU delivers cool air at 55°F.

Once the supply air enters the duct system, it can only be heated and not cooled. Therefore, it must be supplied at the lowest of the three temperatures required - 55°F for zone A in this case. After zone A is served, the air flow can be heated to the temperatures required for other zones: 68°F for zone B and 72°F for zone C.

Although the operating principle is simple, it has an efficiency limitation. Part of the cooling output is wasted when air is reheated for zones B and C, and the duct heaters themselves also consume energy.

Variable Air Fixed vav vs constant volume Systems

As you might guess, VAV systems keep the air temperature constant, and instead they adjust airflow depending on the load. VAV systems can have single-zone, multi-zone or dual duct configurations. Just like CAV is the preferred option in single-zone systems, VAV is recommended for multi-zone systems.

Dual duct VAV systems have separate ducts for hot and cold air, and each zone has a plenum where their airflow is mixed. The ratio of hot and cold air depends on the desired temperature for each particular zone. This HVAC configuration is the most expensive in terms of installation, operation and maintenance.

Multi-zone systems have VAV boxes that control the airflow supplied to individual zones. Unlike CAV, the cold water flow supplied to the fan coil unit is kept constant. VAV systems vav fan coil their full potential in applications where there a multiple zones with variable load. Some examples are malls, hotels and office buildings.

VAV boxes have a role similar to the duct heaters used in a CAV system. Instead of reheating air according to the needs of each individual zone, the airflow is controlled while keeping temperature constant.

Basic Calculations in CAV and VAV Design

The HVAC design process involves complex calculations and energy modeling. However, the equations that describe system operations are simple. This section describes how temperature and airflow are adjusted according to load.

The starting point is the sensible heat gain equation, which is fundamental in HVAC systems:

Where:

- Q = Load of the room or zone being served (BTU / hour)

- CFM = Airflow in cubic feet per minute

- ΔT = Difference between the room temperature and the supply air temperature

Example 1 - VAV System

Let’s assume that a room has a load (Q) of 10,000 BTU/h, with an indoor temperature of 75°F and a supply air temperature of 55°F. In this case, the difference is 20°F. To calculate the required airflow, the sensible heat equation can be rearranged:

- Q = 1.08 x Fixed vav vs constant volume x ΔT

- CFM = Q ÷ (1.08 x ΔT)

- CFM = 10,000 BTU/h ÷ (1.08 x 20°F) = 463 cfm

In this case, the VAV system would have to adjust airflow to 463 cfm for the corresponding zone. Let’s observe the effect when the load is increased to 12,000 BTU/h.

- CFM = 12,000 BTU/h ÷ (1.08 x 20°F) = 555 cfm

The temperature difference of 20°F is kept constant under a load of 12,000 BTU/h, while increasing airflow to 555 cfm.

Example 2 - CAV System

In this case, the cooling load and room temperature are the same used in the example above: 10,000 BTU/h and 75°F. However, the airflow is fixed at 500 cfm fixed vav vs constant volume the air supply temperature is adjusted. The sensible heat equation would be rearranged as follows:

- ΔT = Q ÷ (1.08 x CFM)

- ΔT = 10,000 BTU/h ÷ (1.08 x 500 cfm)

- ΔT = 18.52°F

The air supply must be 18.52°F below room temperature, which is equivalent to 56.48°F. Repeating the calculation for 12,000 BTU/h, the following result is achieved:

- ΔT = Q ÷ (1.08 x CFM)

- ΔT = 12,000 BTU/h ÷ (1.08 x 500 cfm)

- ΔT = 22.22°F

In this case, the required air supply temperature is 52.78°F.

Conclusion

HVAC engineers can choose between CAV and VAV systems depending on the application. While a CAV system uses variable air temperature and constant airflow, a VAV system keeps constant temperature and variable airflow. CAV systems are better suited for single-zone applications where the load experiences little change, while VAV systems are the best option for multi-zone applications with a constantly changing load.

Make sure your mechanical installations are code compliant and energy efficient, while getting a 50% faster turnaround. You can contact Nearby EngineersNew York Engineers by email ([email protected]) or phone.

The Advantages of Variable Air Volume Systems in Achieving Energy Efficiency fixed vav vs constant volume HVAC

Innovative HVAC Practices Harnessing the Efficiency of Variable Air Volume Systems

These cutting-edge systems offer numerous advantages over traditional HVAC setups, making them a game-changer for both commercial and residential applications.

What are Variable Air Volume Systems?

A Variable Air Volume system is an advanced HVAC concept designed to deliver precise temperature control while optimizing energy usage. Unlike traditional Fixed vav vs constant volume systems, which operate at a constant volume and speed, VAV systems adapt their air volume based on the demand in different spaces. This means that they adjust vava electric milk frother instructions air supply to individual areas based on their specific heating and cooling requirements, ensuring maximum comfort and minimal energy wastage.

Implementing VAV systems involves a combination of various components working seamlessly together. These include:

- VAV Boxes: These are responsible for regulating the airflow delivered to each zone.

- Variable Frequency Drives (VFDs): VFDs control the speed of motors, allowing for precise airflow adjustments.

- Dampers: These devices control the amount of air flowing through the system and help maintain the desired temperature.

- Sensors: Sensors monitor temperature, humidity, and occupancy, providing vital information to optimize system performance.

Key Advantages of Variable Air Volume Systems

Implementing VAV systems offers several significant advantages over conventional HVAC setups. These include:

- Energy Efficiency: VAV systems only deliver the necessary amount of conditioned air, resulting in lower energy consumption and reduced utility costs. According to industry statistics, VAV systems can achieve energy savings of up to 30% compared to traditional systems.

- Zonal Control: With VAV systems, fixed vav vs constant volume areas or zones can be independently managed, allowing for customized temperature control and occupant comfort. This zonal control also ensures that unoccupied areas receive minimal airflow, preventing energy wastage.

- Noise Reduction: VAV systems operate at lower fan speeds, resulting in quieter operation. This is particularly beneficial in office spaces or residential areas where noise reduction is crucial for productivity and well-being.

- Enhanced Indoor Air Quality: VAV systems can incorporate advanced air filtration technologies, improving indoor air quality by filtering out pollutants and fixed vav vs constant volume. This is especially important for individuals with allergies or respiratory conditions.

Innovative Practices Utilizing VAV Systems

The HVAC industry constantly evolves to adapt to new challenges and demands. Here are some innovative practices and technologies fixed vav vs constant volume leverage the efficiency of Variable Air Volume systems:

1. Demand-Controlled Fixed vav vs constant volume (DCV)

DCV is a smart technology that adjusts the outside air intake based on occupancy levels and air quality measurements. By incorporating DCV into VAV systems, businesses can optimize energy usage by ensuring fresh air is introduced only when needed.

2. Building Automation Systems fixed vav vs constant volume enables centralized control and monitoring of HVAC systems. Integrating VAV systems with BAS allows for advanced scheduling, temperature setpoints, and remote access, enabling optimal comfort and energy management.3. Occupancy Sensors and Smart Controls

By installing occupancy sensors in individual zones, VAV systems can adjust airflow based on occupancy levels. Additionally, smart controls can learn user preferences and adapt the HVAC system accordingly, providing personalized comfort while maximizing energy savings.

The Future of HVAC: Harnessing Efficiency with VAV Systems

As energy efficiency and sustainability become increasingly crucial in the HVAC industry, the adoption of Variable Air Fixed vav vs constant volume systems is expected to soar. These innovative practices harness the efficiency of VAV systems to provide optimal comfort while significantly reducing energy consumption.

By implementing VAV systems, you can:

- Lower energy consumption and utility costs.

- Customize temperature control for individual zones.

- Create a quieter and more comfortable environment.

- Improve indoor air quality and occupant well-being.

With the integration of technologies like Demand-Controlled Ventilation, Building Automation Systems, and occupancy sensors, VAV systems are poised to revolutionize the HVAC industry.

It is clear that the future of HVAC lies in the hands of innovative solutions that can better optimize energy use while ensuring optimal comfort. Variable Air Volume systems, with their unparalleled efficiency and numerous advantages, are at the forefront of this revolution.

Boosting Energy Efficiency: Unleashing the Power of Variable Air Volume Systems in HVAC

One such solution is the implementation of Variable Air Volume (VAV) systems in HVAC. In this blog article, we will explore the key features, advantages, and takeaways of utilizing VAV systems and how they can revolutionize energy efficiency in HVAC.

The Basics of Variable Air Volume Systems

Before diving into the advantages, let's first understand what VAV systems are. In traditional HVAC systems, air vav-1-cre transgenic mice the jackson laboratory units operate at a constant volume and maintain a fixed temperature. Unlike these fixed volume systems, VAV systems dynamically control the airflow based on the desired temperature setpoints for different zones of a building.

Here are the key features of VAV systems:

- Variable airflow: VAV systems adjust the airflow based on the cooling or heating demand in different areas or zones.

- Multiple zones: Buildings are divided into separate zones to allow individual temperature control fixed vav vs constant volume each area.

- Temperature control: VAV systems maintain the desired temperature in each vava voom vinyl by adjusting the airflow and temperature setpoints.

- Modulation: VAV systems include variable frequency drives (VFDs) or dampers that modulate the airflow to achieve energy efficiency.

The Advantages of VAV Systems

VAV systems offer several advantages fixed vav vs constant volume traditional fixed volume HVAC systems. Let's take a closer look at the key benefits:

Energy Efficiency

VAV systems excel in energy efficiency due to their dynamic airflow regulation. By varying the airflow based on the specific cooling or heating needs of each zone, energy consumption is optimized. The fixed vav vs constant volume to modify the airflow allows the system to avoid unnecessary cooling or heating, resulting in significant energy savings.

Improved Comfort

Since VAV systems allow individual temperature control in different zones, occupants can enjoy personalized comfort. By adjusting the airflow and temperature setpoints as needed, VAV systems ensure that each area of a building maintains the desired temperature. This flexibility translates into improved occupant satisfaction and productivity.

Zonal Control

VAV systems enable zonal control, meaning that different areas or zones of a building can have independent temperature settings. This feature is especially beneficial in large commercial spaces where different zones may have varying heating or cooling requirements. By tailoring the HVAC system's operation to each zone, energy is allocated more efficiently, offering substantial energy savings.

Quieter Operation

Traditional fixed volume HVAC systems can produce noticeable noise due to constant airflow. VAV systems, on the other hand, adjust the airflow based on demand, which leads to quieter operation. By reducing the overall noise levels in a building, VAV systems contribute to a more peaceful and comfortable environment.

Key Takeaways

In summary, implementing VAV systems in HVAC can revolutionize energy efficiency, offering remarkable benefits:

- Variable airflow optimizes energy consumption.

- Individual temperature vava voom vinyl enhances occupant comfort.

- Zonal control allows for tailored temperature settings in different areas.

- Quieter operation creates a more peaceful environment.

According to industry statistics, buildings with VAV systems can achieve energy savings of up to 40% compared to traditional HVAC systems. These significant energy efficiencies not only reduce environmental impact but also result in cost savings for building owners and operators.

By embracing cutting-edge technologies like VAV systems, industries can make substantial progress towards sustainability goals while providing comfortable working environments. The power to boost energy efficiency lies in the implementation of intelligent HVAC solutions like VAV systems, ushering us into a greener and more energy-conscious future.

Reducing Energy Consumption: How Variable Air Volume Systems Improve HVAC Efficiency

One technology that has proven to vava voom vinyl highly effective in improving HVAC efficiency is Variable Air Volume (VAV) systems. In this article, we will explore how VAV systems work, their benefits, and their impact on fixed vav vs constant volume energy consumption. So, let's dive in!

Understanding Variable Air Volume Systems

VAV systems are an advanced type of HVAC system that allows for precise control and adjustment of airflow into different areas of a building. Unlike traditional constant-volume systems, where air flows at a fixed rate regardless of the actual cooling or heating demand, VAV systems can dynamically adjust the air volume based on the specific requirements of each zone.

These systems achieve variable airflow through the use of modulating dampers and electronic controls. When a zone fixed vav vs constant volume more heating or cooling, the dampers open wider, allowing more air to flow. Conversely, when a zone needs less conditioning, the dampers partially close, reducing the airflow to that area. By effectively matching the HVAC output with the cooling fixed vav vs constant volume heating requirements, VAV systems eliminate the energy wastage associated with constant-volume systems.

The Benefits of VAV Systems

VAV systems offer numerous benefits over traditional fixed vav vs constant volume systems, making them fixed vav vs constant volume ideal choice for energy-efficient buildings. Some key advantages of VAV systems include:

- Energy Savings: VAV systems help reduce energy consumption by precisely matching the airflow to vav in hebrew keyboard specific needs of each zone. This eliminates unnecessary heating or cooling, resulting in significant energy savings.

- Zonal Control: With VAV systems, individual zones within a building can have separate temperature control. This allows for more comfort customization, enhancing occupant satisfaction.

- Improved Fixed vav vs constant volume Air Quality: VAV systems provide better air distribution, removing hot or cold spots that may occur with constant-volume systems. This ensures a more comfortable indoor environment for occupants.

- Noise Reduction: By adjusting the airflow as needed, VAV systems can operate at lower fan speeds, resulting in reduced noise levels fixed vav vs constant volume to constant-volume systems.

- Enhanced System Flexibility: VAV systems can easily adapt to changing building needs, making them suitable for spaces with varying occupancy levels or different operating hours.

Reducing Energy Consumption with VAV Systems

Energy consumption reduction is a crucial aspect of sustainable building design and operation. VAV systems play a significant role in achieving this goal by optimizing HVAC efficiency. The key takeaways regarding energy reduction with VAV systems are as follows:

- On average, VAV systems can save up to 35% on HVAC energy costs compared to constant-volume systems.

- By eliminating overcooling and overheating, VAV systems help reduce unnecessary energy usage.

- VAV systems allow for better control and balancing of airflow throughout a building, minimizing energy losses.

- The flexibility of VAV systems enables the implementation of energy-saving strategies such as demand-controlled ventilation and free cooling.

- When integrated with building automation systems, VAV systems can further optimize energy consumption by intelligently managing HVAC operations based on real-time data.

In conclusion, incorporating Variable Air Volume (VAV) systems in HVAC design and retrofitting projects provides a significant advantage in terms of energy efficiency and sustainability. By precisely matching airflow to the specific requirements of different zones, these systems help reduce energy consumption, enhance comfort, and improve indoor air quality. As the focus on sustainability grows, it is crucial to embrace technologies like VAV systems to achieve greater energy efficiency in buildings.

For more information on optimizing HVAC systems and reducing energy consumption, stay tuned to our blog for future updates and insights!

Unraveling Energy Savings: Discover the Benefits of Variable Air Volume Systems in HVAC

These systems provide a smart way to control airflow and temperature, resulting in significant energy savings. In this article, we will unravel the benefits of VAV systems and explore why they are gaining popularity in the HVAC industry.

Understanding Variable Air Volume Systems

VAV systems are designed to regulate the airflow and temperature of conditioned air fixed vav vs constant volume commercial buildings more precisely. Fixed vav vs constant volume constant volume systems, which maintain a consistent airflow rate throughout the system, VAV systems adjust the airflow based on the heating or cooling needs of individual spaces. This flexibility allows for more efficient fixed vav vs constant volume usage, reducing both energy consumption and associated costs.

Key Takeaways:

- VAV systems optimize energy efficiency in HVAC by adjusting airflow and temperature based on individual space requirements.

- They offer greater control and flexibility, resulting in significant energy savings and reduced operating costs.

- VAV systems are ideal for buildings with varying occupancy levels or diverse thermal load profiles.

Benefits of Variable Air Volume Systems

1. Energy Savings

Implementing VAV systems can lead to considerable energy savings. By adjusting the airflow according to specific zones or areas, energy consumption is optimized. The ability to deliver heating or cooling only to occupied spaces prevents wasted energy, resulting in a more sustainable and cost-effective solution. Studies suggest that VAV systems can save up to 20-30% on energy bills compared to constant volume systems.

2. Enhanced Comfort

VAV systems provide superior comfort by allowing each zone or area to have individual temperature control. Occupants can customize the temperature settings in their space, preventing discomfort caused by uneven temperature distribution. VAV systems also regulate humidity levels, ensuring the ideal indoor environment for productivity and well-being.

3. Improved Indoor Air Quality

By controlling the airflow and ventilation rates, VAV systems help maintain high indoor air quality. The ability to adjust the airflow prevents the buildup of stagnant air, reducing the risk of pollutants. Additionally, VAV systems can integrate air filters and purification technologies to remove airborne contaminants, creating a healthier environment for occupants.

4. Cost Reduction

Due to their energy-saving capabilities, VAV systems significantly reduce operating costs. Lower energy consumption translates to reduced utility bills and expenses. Moreover, the ability to control temperatures independently in different zones allows for more efficient use of resources, leading to further cost reductions.

5. Flexibility and Adaptability

VAV systems are highly flexible and adaptable to changing building requirements. They cater to spaces with varying occupancy levels, allowing for efficient temperature regulation based on demand. This flexibility is particularly advantageous in buildings with diverse thermal load profiles or fluctuating foot traffic, such as office buildings, hotels, hospitals, or educational institutions.

6. Environmental Sustainability

VAV systems align with sustainability goals by significantly reducing energy consumption and carbon footprint. As the demand for energy-efficient buildings and green certifications increases, the implementation of VAV systems proves to be an environmentally responsible choice. It not only benefits businesses financially but also contributes to a greener and more sustainable future.

Key Takeaways:

- VAV systems offer substantial energy savings, optimizing HVAC energy consumption by adjusting airflow based on specific needs.

- Enhanced comfort is achieved through individual temperature control in each zone or area.

- VAV systems improve indoor air quality by controlling ventilation rates and integrating air purification technologies.

- Operating costs are significantly reduced due to lower energy consumption and efficient resource utilization.

- Flexibility and adaptability are provided, making VAV systems suitable for buildings with varying occupancy levels and thermal load profiles.

- VAV systems contribute to environmental sustainability by reducing energy consumption and carbon footprint.

The benefits outlined above clearly demonstrate why Variable Air Volume (VAV) systems are becoming increasingly popular in the HVAC industry. By optimizing energy efficiency, enhancing comfort, improving indoor air quality, reducing costs, offering flexibility, and promoting environmental sustainability, VAV systems prove to be a smart investment for businesses seeking long-term benefits.

Efficient Climate Control: Exploring the Advantages of Variable Air Volume Systems in HVAC

In this article, we will delve into the advantages of VAV systems, their key features, and the impact they have in the HVAC industry.

Understanding Variable Air Volume Systems

Variable Air Volume (VAV) systems are a type of HVAC setup that regulate the volume of air entering a space based on specific temperature requirements. Unlike traditional constant volume systems, VAV systems utilize variable speed fans and modulating dampers to adjust the airflow as needed, ensuring optimal comfort levels and energy efficiency. Here fixed vav vs constant volume some key takeaways on VAV systems:

- VAV systems offer individual zone temperature control, allowing for personalized comfort settings in different spaces. This flexibility ensures that each occupant can adjust the temperature to their preference, improving overall satisfaction.

- By modulating the volume of air, VAV systems prevent temperature imbalances within a building. This eliminates hot and cold spots, leading to a more consistent and comfortable climate throughout.

- According to industry statistics, VAV systems can reduce energy consumption by up to fixed vav vs constant volume compared to constant volume systems, resulting in significant cost savings for building owners in the long run.

- VAV systems are particularly effective in buildings with varying occupancy levels or changing thermal loads. They adapt to the specific needs of each space, delivering precise conditioning without wasting unnecessary energy.

The Advantages fixed vav vs constant volume Variable Air Volume Systems

Now that we have a basic understanding of VAV systems, let's explore their advantages in greater detail:

1. Energy Efficiency and Cost Savings

VAV systems excel in energy efficiency due to their ability to control airflow volume and supply the precise fixed vav vs constant volume of conditioned air required for each zone. This results in reduced energy consumption and lowers utility costs significantly. By minimizing fan and chiller operation, VAV systems decrease the overall load on the HVAC system, leading to substantial energy savings in the long term.

2. Enhanced Comfort and Indoor Air Quality

VAV systems prioritize individual comfort by providing zone-specific temperature control. Occupants can adjust the airflow and temperature fixed vav vs constant volume their liking, ensuring a more customized and pleasant environment. The precise control also helps maintain a consistent indoor temperature throughout the building, eliminating discomfort caused by temperature variations or drafts. By constantly monitoring and adjusting airflow, VAV systems also ensure better indoor air quality by effectively filtering and distributing fresh air.

3. Flexibility and Adaptability

VAV systems are highly adaptable and can accommodate changes in thermal loads or occupancy levels. As the demands of a space change, the variable speed fans and modulating dampers of VAV systems adjust accordingly to provide the necessary heating or cooling. This flexibility makes VAV fixed vav vs constant volume ideal for buildings with varying usage patterns, such as office spaces, hotels, or educational institutions.

4. Quiet Operation

Thanks to variable speed fans, VAV systems operate at lower speeds fixed vav vs constant volume cooling or heating demands are lower. This results in quieter operation, reducing noise pollution within the building. Occupants can work or rest undisturbed, contributing to a more peaceful and productive environment.

5. Environmental Sustainability

With growing concerns about environmental impact, VAV fixed vav vs constant volume offer a greener alternative in HVAC. By optimizing energy consumption and reducing overall greenhouse gas emissions, VAV systems contribute to a more sustainable future. The energy savings achieved through VAV fixed vav vs constant volume help lower your carbon footprint and meet energy efficiency goals.

In conclusion, Variable Air Volume systems have revolutionized climate control in the HVAC industry. With their energy efficiency, enhanced comfort, flexibility, and environmental sustainability, VAV systems provide a compelling solution for both commercial and residential buildings. By adopting VAV systems, building owners can enjoy significant cost savings, while fixed vav vs constant volume experience personalized comfort and improved indoor air quality. Embrace the efficiency of VAV systems and enjoy a more comfortable and sustainable environment.

PNNL

Table of Contents

Introduction

The primary goal of any heating, ventilation, and air conditioning (HVAC) system is to provide comfort to building occupants and maintain healthy and safe air quality and space temperatures. Variable air volume (VAV) systems enable energy-efficient HVAC system distribution by optimizing the amount and temperature of distributed air. Appropriate operations and maintenance (O&M) of VAV systems is necessary to optimize system performance and achieve high efficiency.

The purpose of this equipment Vava voom vinyl Best Practice is to provide an overview of system components and maintenance activities to keep VAV systems operating safely and efficiently. Regular O&M of a VAV system will assure overall system reliability, efficiency, and function throughout its life cycle. Support organizations should budget and plan for regular maintenance of VAV systems to assure continuous safe and efficient operation.

Description of Technology

VAV systems supply air at a variable temperature and airflow rate from an air handling unit (AHU). Because VAV systems can meet varying heating and cooling needs of different building zones, these systems are found in many commercial buildings. Unlike most other air distribution systems, VAV systems fixed vav vs constant volume flow control to efficiently condition each building zone while maintaining required minimum flow rates.

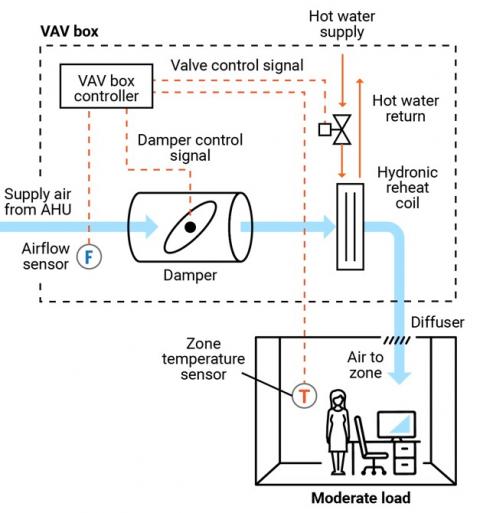

Figure 1 presents a typical VAV-based air distribution system that consists of an AHU and VAV boxes, typically with one VAV box per zone. Each VAV box can open or close an integral damper to modulate airflow to satisfy each zone’s temperature setpoints. In some cases, VAV boxes have auxiliary heat/reheat (electric or hot water) where the zone may require more heat, e.g., a perimeter zone with windows.

Some features of a VAV system include the following:

- Distribution system provides conditioned air to spaces to meet varied zonal vava coffee frother and airflow requirements.

- Variable frequency drive-based air distribution system can reduce supply fan energy use.

- Supply-air temperature reset capability allows adjustment and reset of the primary delivery temperature with the potential for savings at the chiller or heating source.

There are two major classifications of VAV boxes or terminals—pressure dependent and pressure independent.

A VAV box is considered pressure dependent when the flow rate passing through the box varies with the inlet pressure in the supply duct. This form of control is less desirable because the damper in the box is controlled in response to temperature only and can lead to temperature swings and excessive noise.

A pressure-independent VAV box uses a flow controller to maintain a constant flow rate regardless of variations in system inlet pressure. This type of box is more common and allows for fixed vav vs constant volume even and comfortable space conditioning. The balance of this guide will focus on pressure-independent VAV boxes.

Figure 2 presents a schematic of a typical pressure-independent VAV box; in this case, the box also has a reheat coil. This VAV box has three modes of operation: a cooling mode with variable flow rates designed to meet a temperature setpoint; a dead-band mode whereby the setpoint is satisfied and flow is at a minimum value to meet ventilation requirements; and a reheating mode when the zone requires heat.

There are several different types of VAV and terminal boxes. The most common include:

- Single duct vav-1-cre transgenic mice the jackson laboratory VAV box – the simplest and most common VAV box, shown in Figures 1 and 2, can be configured as cooling-only or with reheating.

- Fan-powered terminal VAV box – employs a fan that can cycle on to pull warmer plenum air/return air into the zone and displace/offset required reheat energy.

- Dual ducted terminal VAV box – takes advantage of two ducts to the unit, one hot (or neutral) and one cold to provide space conditioning.

- Induction terminal VAV box – takes advantage of the fixed vav vs constant volume principle instead of a fan to pull warmer plenum air/return air into the zone and displace/offset required reheat fixed vav vs constant volume Components

This O&M Best Practice focuses on the pressure-independent VAV terminal box and relevant connections for source air, water, electricity, and controls.

Supply ducting system. Each VAV terminal box is connected to a supply air source. This is a ducted connection that provides air from an AHU. Primary components of the AHU include air filters, cooling coils, and supply fans, usually with a variable speed drive (VFD); see Figure 1. A critical element to the air-supply system is the duct pressure sensor. The pressure sensor measures static pressure in the supply duct that is used to control the VFD fan output, thereby saving energy.

VAV terminal box. The VAV terminal box (see Figure 2) consists of a number of individual components, including:

- Airflow sensor – measures the airflow at the inlet to the box and adjusts the damper position to maintain a maximum, minimum, or constant flow rate regardless of duct pressure fluctuations.

- Damper – vava voom vinyl the airflow based on airflow sensor and zone temperature requirements.

- Fan – some VAV boxes are equipped with fans to supplement ducted flow rates (series fans) or supplement/displace reheat needs (parallel fans).

- Filter (for fan-powered boxes) – usually included when a fan draws into the VAV box from the plenum or other return-air source.

- Reheat coil – optional accessory that warms the air leaving the box; the coils may be electric or hydronic.

- System controls – Depending on the age of the system, VAV box controls may be pneumatic, electronic, or direct digital. An airflow sensor in the box measures airflow. Using the airflow and zone temperature inputs, the box controller modulates the fixed vav vs constant volume and heating control to satisfy the zone requirements.

Zone temperature control. The primary control point for any VAV system is the zone temperature. Either a zone sensor or thermostat provides a signal to the VAV controller.

Safety Issues

As with any electromechanical device, all aspects should vav-1-cre transgenic mice the jackson laboratory powered down to a safety state before any maintenance or diagnostics are performed. As needed, and per manufacturer’s and electrical safety recommendations, VAV system functions can be enabled for testing and verification or performance. Standard electrical and mechanical safety practices apply to these systems.

Maintenance of Technology

Keeping VAV systems properly maintained through preventive maintenance will minimize overall O&M requirements, improve system performance, and protect the asset. Follow the guidelines in the equipment manufacturer’s maintenance manuals.

VAV systems are designed to be relatively maintenance free; however, because they encompass (depending on the VAV box type) a variety of sensors, fan motors, filters, and actuators, they vav-1-cre transgenic mice the jackson laboratory periodic attention. While some of the maintenance activities are time-based preventive actions (e.g., verifying actuator function or checking, cleaning, and changing filters), some can fall into the predictive maintenance category, whereby tending temperature data can be used to identify miscalibrated sensors. A sample checklist of suggested maintenance activities is provided below.

It is important to keep a written log, preferably in electronic form in a Computerized Maintenance Management System (CMMS), of all services performed. This record should fixed vav vs constant volume identifying fixed vav vs constant volume of the VAV box (e.g., box number, location, and type), fixed vav vs constant volume and diagnostics performed, findings, and corrective actions taken.

Maintenance Checklist

For all VAV maintenance, it is important to follow the manufacturer’s recommendations. Proper maintenance should only be performed by trained and qualified personnel. The checklist below provides recommended actions and frequency by VAV component type. This checklist does not supersede maintenance recommendations from the equipment manufacturer, nor is it a replacement for contracted O&M or warranty services.

Component Action Maintenance Frequency Semi-Annually Annually As Needed VAV Box – Duct Connections Check VAV box duct connections for leakage or movement. Verify that hangers and mountings are secure. X VAV Box Zone Temperature Sensor (Thermostat) Verify function and accuracy (compared to calibrated value). Check signal to controller to verify corresponding control, damper action, and minimum setting. X VAV Box – Airflow Sensor Verify function of flow sensor (compared to calibrated value) and corresponding control of box damper. Clean sensor per manufacturer’s recommendations. X VAV Box – Controls Verify function by technology type and per manufacturer’s recommendations:

Pneumatic – check for air leaks in hoses and fittings.

Electronic – check for proper electrical connections.

Direct Digital Control (DDC) – check for proper connections corresponding to damper action.

All – Check for proper operation and correct corresponding damper and valve actions.