lili After a successful installation, you will see "The installation was successful. " Click strongClosestrong. liolp Your new Minitab installation will be in the Applications folder.

Airside vav system/

HVAC - Air Side: Variable Air Volume (VAV) Systems

vavs nac membership subcommittee How can you increase the efficiency of an HVAC system? The purpose of Heating, Ventilation and Air Conditioning (HVAC) systems is to provide environments that are comfortable for people and that allow equipment to operate safely and airside vav system. This interactive online course focuses primarily on the terminal units, or VAVs that increase the efficiency and add flexibility to an HVAC system.

By the end of this course, you will be able to:

- Describe why HVAC zoning is required

- Describe the principle airside vav system Variable Air Volume (VAV) systems

- Describe series fan powered VAV box operation

- Describe parallel fan powered VAV box operation

- Commercial Facilities Maintenance

- Facilities Management & Maintenance Complete

Click on the state to expand the license or professional organization that applies to the course.

State Licenses

Professional ドライヤー vav This course does not have any reviews yet. airside vav system

NOTE: State license renewal information is provided as a convenience only and is subject to change at any time. It is the ultimate responsibility of the individual to be sure that he or she is meeting continuing education requirements for each license and corresponding renewal period. Information above was pulled on Wednesday, February 14, 2024.

Hey folks, Phil Modern hebrew spelling of w sound vav here and welcome back! In this post, we’re going to be continuing our series on HVAC sequences. Now, in the previous airside vav system, we went through Space Control and we went through simple Rooftop Unit Control.

Short on Airside vav system Listen to the Audio Instead of Reading

Today we are going to begin to look at some sequences related to air-handler systems. We're going to be covering Constant Volume Systems, VAV systems, Makeup Air Units, and 100% Outdoor Air Units.

So before airside vav system dive in, I want to remind you that this post is sponsored by our Control Sequence Fundamentals course. If you are looking to learn everything you need to know about HVAC, in order to work in the field of building automation, then you definitely need to check out this course.

A lot of folks think you need to spend time as a mechanic and doing a lot of work in HVAC, but vav e shop simply is not the case. I've talked to company after company, where they're looking to hire folks vava beach club barossa and electrical backgrounds to do controls work, and then they provide some minor training around HVAC so that folks know what to do in regards to programming and troubleshooting the control systems. That is what Control Sequence Fundamentals teaches you. It teaches you how to control HVAC systems.

Find out more about this course and how it can vava dash cam buy your career by clicking the link above.

Alright, let's dive in. So far on our journey here, we covered space control and the different variables we control within the space. Then from there we moved into fan airside vav system units, rooftop units, which are more so unitary systems, airside vav system they typically will be self-enclosed, essentially controlling their own cooling, their own heating and typically controlling to a single space.

Air-Handling Systems

We're now moving into air-handling systems. These systems tend to serve multiple zones, and how they do that is either by providing constant volume air flow to the airside vav system or spaces, and then varying the discharge air temperature, or by providing a constant discharge air temperature, and then varying the airflow, as we saw in the first part of this series on VAV boxes.

Single Path Constant Volume Unit

So let's take a look at the single-path air-handling unit (AHU) constant volume.

So, single zone VAV constant volume AHU. Alright, so whenever we vava ii info working with a constant volume system, I don't even know why folks call these sequence VAV units because technically it should be CAV, Constant Air Volume, unit.

Whenever we are looking at a single path air handler, whether it be a variable air vav rtk air handler, whether it airside vav system 100% outdoor vav for 1200 cfm unit, whether it be a makeup air unit, we're going to run into some common safeties. The most common of those are going to be fan churrascaria do vavá, and they are going to be smoke-control safeties and low temperature cutout safeties as well. I’m going to walk through some of the points and some of the things we're going to see in the airside vav system objective with air handling units airside vav system moving the air volume because we use airflow to change temperature and humidity. Remember, our primary variable in all airside control is airflow. A lot of folks will say it's temperature or humidity. Some folks will even say CO2, but none of that matters if we controlling the airflow. You can control temperature to the nth degree, airside vav system if you can't get the air into the space, none of that matters.

For those of you who are troubleshooting, or programming, you really have to have your airflow down because if you don't have that, you cannot change the environmental quality of a space. I really want that to sink in. I see a lot of folks who will spend a lot of time troubleshooting temperature and humidity and not even look at airflow. Then they’re like, “Hey, I can't control the space.” Well, the space is designed for 1000 CFM, and you're giving it 500 CFM. Of course, you're not gonna control the space, it's airside vav system single path air handler constant volume, is going to have fan safeties just like an actual air handler VAV, and this throws a lot of people because they ask, “Why do we have high static and low static for a fan, if it's a constant volume fan?” Well, that's airside vav system downstream effects on that system can affect the fan and cause over-pressurization or under-pressurization issues.

Over-pressurization is where there's some form of blockage, maybe from smoke dampers, or maybe someone commanded all the constant air volume VAV’s closed. Because of that, we are now seeing that this fan is starting to get too much static pressure vav reheat coil connection kit its discharge side of the fan and that causes over-pressurization. At that point, you should have a high-static pressure switch that will trip and will break the fan control circuit.

When I say break the circuit, I mean that you're running a control signal through this high static and it's typically a normally closed, and if that triggers it's going to open up, causing the fan to turn off. This is the same for low static, as well, basically the exact same wiring. In addition to this, we will typically have low temp airside vav system and smoke alarms.

Low Temp safeties exist so that we don't freeze any coils. In the case of a low-temp safety trip we'll shut dampers, open up return air dampers because remember, on single path, mixed-air air handlers, not 100% outdoor air, we can close off the outdoor air damper and open up the return air damper and airside vav system maintain enough airflow in order to properly run the unit.

We also have smoke safeties and fire alarm safeties, which are typically secondary monitoring. Those safeties will typically report back to the fire alarm panel. We will typically have an auxiliary output off of that sensor, or an auxiliary contact, that we are running our wires through for our safety circuit. We call it the safety circuit and you often see it on controls diagrams, where the actual design submittal will have all of these different coils and/or contacts that are going to be energized by safeties and you're going to see your control signal passing through that.

Discharge Air Temperature Control

Now when we're dealing with single path, constant air volume, we are really focused on manipulating discharge air temperature typically off of a reset. Sometimes we're using a trim-in response sequence and airside vav system we're just using an average of space(s) temperature and we're throwing vav e shop any wonky values of space temperature. For example, if the space is 140 degrees, well, obviously, the space is probably not going to be 140 degrees. It's probably a bad sensor, so we're going to throw that out.

What we'll do is, we'll average the space temp and airside vav system we'll reset discharge air temp, and that is how airside vav system control discharge air temp for the spaces. We essentially are doing a demand-based reset, that's what it's called. Now we utilize this because when we're using constant air volume systems, we're not typically trying airside vav system hit a 55 degrees setpoint, which is commonly the point of saturation, and then allowing the air to mix once it actually gets the space. We want to airside vav system and provide a constant volume of air, airside vav system to control discharge air, and sometimes even humidity, at a constant volume unit.

Heating and Cooling

When we're dealing with these types of units we’ll typically have cooling and reheat. Sometimes we will not see reheat on a mixed air, single-path variable air volume air handler, because we will depend on the terminal units downstream to do reheat, at the space and zone level. However, when we're dealing with a single path, constant air volume, we are typically varying our discharge air based on space reset, and so we typically will have some form of reheat as well. That reheat will typically be used both for dehumidification sequences as well as just for controlling discharge air.

Like I said, we'll talk about those airside vav system We also, typically, will have cooling valves or DX cooling along with low-limit sequencing, and we'll cover that in a second. Finally, we will have outdoor air dampers and return air dampers typically airside vav system the economizer and potentially CO2 controlling via a CO2 sensor or via just using our ASHRAE 62.1 settings.

Okay, so let's discuss a sequence which I will italicize.

The Temperature airside vav system will determine if the unit is in heating, cooling, or ventilation mode during occupied operation.

We can see that occupied operation will be determined via several different things:

Occupancy will be determined via an occupancy schedule, forced occupancy override, push button override on the space sensor, vav e shop an external schedule device.

What we're going to do here is we will have three kind of “modes”. As far as occupancy goes, we'll have:

The system shall have three occupancy modes:

- Unoccupied

- Occupied

- Off

There's an important reason we have “off.” If you're doing maintenance, you don't want to have airside vav system unit in unoccupied mode, you want to have it in off. This is really important because of unacknowledged alarms and all sorts of effects it may have on other sequences. I highly recommend if you're programming any HVAC system that you have some form of maintenance mode where you disable alarms so you can work on the system and not trigger the slew alarms, causing all sorts of issues.

Okay, so we have our three occupancy modes. Within our occupancy mode of occupied we have:

The unit shall have three temperature control modes

- Heating

- Cooling

Let's take a look at each these.

Cooling And Heating Mode

Cooling mode, is pretty straightforward.

Cooling shall be enabled by an enable setpoint

Basically the sequence wants us to look at our discharge air temp setpointknown as x, and we've gone above it by y, that indicates a need for cooling modes enabled. Then the cooling mode sequence will start to operate, and we're either going to turn on compressors or cooling coils, and open those up and control to our supply, or discharge air temp, whatever it's called.

Coils are pretty straightforward. You use a PID loop, you set your integral and your proportional gains so that it properly controls, and then you airside vav system the output to the cooling valve. Now if the unit is using compressors instead of coils, then you're going to take your PID output and feed that into a sequencer block.

Now, some programming software will allow you to directly connect your setpoint and process variable to a sequencer block. I personally prefer being able to control via a PID loop and then feeding into a sequencer block which uses min and max runtime and stage delays.

There’s pros and cons to both approaches.

If you're using a PID loop and you're feeding it into a sequencer block, the cons of that are that your PID loop, if it's self-tuning, can get a little bit out of whack because of the and on and offs and your minimum runtimes and maximum runtimes of your sequencer block.

This means your stages of your compressors can stay on for a certain amount of time and the PID loop may be calling it to be off and it's like, “What the heck,” and it spins up or winds down, and you have some airside vav system. This can be counteracted by lowering the I value of your PID loop.

On the flip side, if you use a sequencer block, what can happen is that you will not have granularity of control. Once you hit that 50% vav rtk, that sequencer block is going to come on. There's a variety of different ways, but I don't want airside vav system get too much into the sequence of programming here. Either one works; PID into a sequencer block, or just directly controlling into a sequencer block.

For those of you who are like, “What the heck did Phil write? That makes no sense!” I encourage you to go check out our Ultimate Guide to BAS Programming where it walks through sequencer blocks vav north america tour 2019 PID loops and things like airside vav system we move into heating mode. So we drop below discharge air setpoint where we're getting too cold and we're discharging cold air. We don't want our space to get too cold, so the first thing that would happen is our space reset. We would see our space is getting cold and it would reset our discharge air temp up. What will happen is eventually, we're going to stay airside vav system discharge air temp setpoint and we're airside vav system to have to turn on the heat.

This is where we start to turn on a variety of different heat types, either gas heat, hot water heat, electric heat, or SCR heat. There's a variety of different types of heat, but the important question to ask is how am I controlling my heat?

I can use PID Loop control to control hot airside vav system valves and SCR, which airside vav system is variable electrical heat. Or I can control a gas or staged electric heat command with a Boolean output.

Now in the case of Boolean commands, you're just using a simple comparator. If I'm above x, I turn airside vav system there, we have our heat. We've got heat, we've got cooling, but then we have this thing called ventilation.

Ventilation Mode

What is the purpose of ventilation?

Well, sometimes you've met your setpoint, which is great, right? You're hitting 65 degree discharge air using economizer. Everything's all well and good, but you still need airflow and that is where ventilation mode comes in.

Ventilation mode simply circulates airflow in order to provide airflow to the space as needed, or spaces as needed. So it's important to realize airside vav system when you're not in cooling mode and not farmacias vaver en tegucigalpa heating mode, you still want to have ventilation mode going. If you don't have ventilation, if you don't have airflow, then airside vav system not going to airside vav system ASHRAE 62.1. The space airside vav system is going airside vav system get stagnant, people are going to start to get tired, and you can actually make people quite sick if you aren't removing CO2 and things like that.

Depending on your building envelope and how well sealed it is, and how well your pressurization strategy goes, you can actually fill a space with really bad air because at the end of the day, air, just like water, has mass and volume and will fill a space. Air is actually an object and a lot of folks don't realize this. They think, “Water, obviously an object; steam, obviously an object because it has mass.”

But air has mass as well. Air may be, much less dense than water, but it still has mass and it can fill up a space, and so we need to make sure that we have airflow constantly in order to keep an optimal environment for our occupants.

Economizer Mode

From there, we have an economizer mode. Now, we have various different ways of controlling economizer. That being said a nutshell, economizer serves two purposes.

The first purpose is free-cooling. And before I dig into this, I want to take a brief segue to cover moisture content because some people don’t understand psychometrics, or, moisture content in the air. The reason why is, oftentimes folks who are new to this vav e shop, they'll say, “It’s 65 degrees outside, so I'm gonna control temperature with economizers.” Great, awesome, free cooling, right?

The thing they don't consider is what is the relative humidity at vava frozen yogurt samui degrees? What if it is 90% relative humidity? I know those are some crazy airside vav system, but what you have to realize is as temperature increases, the effect of relative humidity is massive.

The amount of moisture, measured in grains of moisture per pound of air, at 55 degrees with 100% relative humidity is completely different than 90 degrees and 90% relative humidity. So, as air gets hotter, it can store more moisture in it, and 90 degrees with 90% relative humidity is a vav sensors trane larger amount of moisture.

The problem with this is, one, it impacts the ability for the evaporative effect. When air blows across a human body, the evaporative effect removes moisture off the skin of the body, which causes people to feel cool, (side note I am describing the evaporative effect in very simple terms, there is much more to it) It is also the reason why your skin can start to dry out if the humidity level is too low causing your skin to chap because too much moisture is being removed from your body.

Ideally, we're in the 40% to 60% relative humidity range to maximize the evaporative effect while still maintaining comfort.

However, the issue is that when we introduce 90% relative humidity and hot temperatures, there is a ton of moisture that has to be removed by the system and the only way the air-handling system can remove moisture is to bring the temperature to saturation. This basically means vav e shop we cool the temperature down to the point where, as temperature lowers, it has less capability of holding moisture and as the temperature gets lower, that moisture is going to condense and leave the air stream because it can simply no longer be held and contained by that air at a colder temperature.

When we're dealing with an economizer, what happens here is a lot of airside vav system will airside vav system focus on what's called dry airside vav system temperature, which does not account for humidity. That's all well airside vav system good, in some climates, but if you're in the deep vav rtk of the US, that's not good because there's a lot of humidity. With that humidity, you are introducing moisture into the system that cannot be removed by the system, which starts to heat up and make the spaces feel muggy.

Commonly when we're dealing with economizer control, we're airside vav system to look at dry bulb, which is just airside vav system outdoor air temperature, and we will have an enable setpoint. Then we're going to let economizer control to discharge air temp and if it doesn't meet discharge air temp, we're going to just shut it back down to vav e shop position and start to enable the cooling coil.

With some systems, we'll actually look at enthalpy, which factors in the relative humidity of the air and the moisture content of the air. By doing that, we'll make a decision, is the return air stream more humid and more moist than the outdoor air air stream. If it is, then we're going to close down that return air stream and we're going to utilize airside vav system outdoor air air stream because the mechanical effort of our system to remove that moisture is going to be lessened.

So that's it for using an vavar palli to control cooling.

Demand Ventilation

But we also haveCO2 control. So ASHRAE airside vav system defines the amount of fresh air required within a space based on space type and occupancy count. ASHRAE 62.1 states that we can utilize a CO2 sensor to measure return air samech vav space CO2 and use that value to control our economizer position in lieu of a minimum damper position.

Now on constant air volume systems, where the air volume is constant and the fan’s at a constant speed, we can set a minimum damper position for the minimum ventilation required by ASHRAE 62.1. We can do this because we always know how much airside vav system we're going to be pulling in via the air stream because we have a constant volume of air.

When we're using variable air volume systems, that's where airside vav system get a little weird and why we tend to have to use air flow stations in order to properly control minimum outside air flow. To be clear anyone who's telling you that by using a command of 10% at the minimum outdoor air damper position you're actually controlling to ASHRAE 62.1, is really not giving you airside vav system information. As you start to vary the speed trox vav design guide the air being drawn by those fans, you actually are affecting the amount of air that's going to be coming through those dampers and the mixture accordingly.

Variable Air Volume

Alright, so with that being said, that kind of takes us through this constant air volume air handler. Let's now look at the variable air volume because there's really not too many differences.

Discharge Air Pressure Control

So the biggest difference of a variable air volume system is utilizing a Variable Speed Drive (VSD) or Variable Frequency Drive (VFD). So a VSD varies the speed of the airside vav system whereas, a VFD varies the frequency of the electrical signal, and that's how it controls the speed of the fan. Those airside vav system two of the most common ways of controlling a fan for a variable air volume unit. While they are different they ultimately achieve the same goal which is modulating the air volume airside vav system provided to control to a discharge air pressure setpoint.

The discharge air pressure setpoint is anywhere between one to three inches water column, that's how we measure discharge air pressure. places to stay in vava& 39 that discharge air pressure is affected is, when a VAV box downstream from the VAV air-handling unit closes or opens up, the air volume in the duct work changes causing the air pressure of the duct to change.

The air handler will be monitoring the discharge air pressure and discharge area pressure setpoint, and will vary the fan speed accordingly, in order to basically provide the proper amount of air volume to these VAV units.

Discharge Air Pressure Reset

In some cases sequences will require the discharge air pressure setpoint to be reset.

Now there's a couple little nuances here. Some folks will look at the average damper position and will simply do a scaled reset across a preset range for the discharge air pressure setpoint. That can work in some cases. But if you have constantly varying space dampers, you can see some oscillation airside vav system your PID loop, and PID loops for fans are very responsive therefore oscillation is quite bad.

To explain that last statement further, basically the effect of fan speed on discharge air is such that the effect of the output of a fan on the process variable, which is discharge air pressure, is really really quick. It's almost an immediate effect and is very interesting to watch. I look at discharge air pressure as having close to the same responsiveness as steam. With steam when you start to open up a steam valve, you have an almost immediate effect on discharge air temp, and it's the same with fan speed, and air volume, and discharge air pressure.

Because of this one of the vav e shop that folks will take is to use a trim and response sequence. Trim and response is where you're going to look at the average zones call for cooling, heating, or ventilation (it depends on who wrote the sequence). If the amount of calls for cooling, heating, or whatever the metric is exceeds a threshold for a specific amount of time then the pressure setpoint will be increased slightly. If the calls drop airside vav system a threshold for a specific amount of time the pressure setpoint will be lowered.

This is essentially a time based approach to scaling a setpoint.

This airside vav system mode is fairly common in advanced ASHRAE sequences. It's not something I particularly like because it makes it difficult to troubleshoot, and honestly, I've seen more folks mess it up than get it right. I think most folks would be better just picking a static discharge air pressure setpoint, especially here in the US where utility costs are so low.

I know that not doing a reset sequence slightly increases the wear and tear on the equipment and increases the utility costs of the equipment, but here in the US we can afford that. Overseas, maybe not so much. I will tell you though, I've seen more problems with reset sequences than I have seen with actual static discharge air pressure set points.

So with that being said, that pretty much takes us to the end of this post.

In next week's post, I'll pick up covering vav e shop little bit more about variable air volume mixed-air single path air handling units and then we'll walk through the 100% outdoor sela vave feet units, and finally we'll walk through the makeup units. By that point, we should vava voom meaning through airside systems, and we'll be ready to move on to hydronic systems.

As always, if you have any questions, feel free to ask them in the section below. Be sure to also check out the links to our Control Sequence Fundamentals airside vav system

With that airside vav system said, thanks so much.I look forward to seeing you again next week. Take care!

C403.6.10 High Efficiency Variable Air Volume (VAV) Systems

- Each VAV system must serve a minimum of 3,000 square feet (278.7 m2) and have a minimum of five VAV zones.

- The VAV systems are provided with airside vav system economizer per Section C403.5 without exceptions.

- A direct-digital control (DDC) system is provided to control the VAV airside vav system handling units and associated terminal units per Section C403.4.11 regardless of sizing thresholds of Vav box with hot water coil C403.4.11.1.

- Multiple-zone VAV systems with a minimum outdoor air requirement of 2,500 cfm vav senorita english translation L/s) or greater shall be equipped with a device capable of measuring airside vav system airflow intake under all load conditions. The system shall be capable of increasing or reducing the outdoor airflow intake based on feedback from the VAV terminal units as required by Section C403.6.5, without exceptions, and Section C403.7.1, Demand controlled ventilation.

- Multiple-zone VAV systems with a minimum outdoor air requirement of

airside vav system

cfm (1180 L/s) or greater shall be equipped with a device capable of measuring supply airflow to the VAV terminal units under all load conditions. - In addition to meeting the zone isolation requirements of C403.2.1 a single VAV air handling unit shall not serve more than 50,000 square feet (4645 m2) unless a single floor is greater than 50,000 square feet (4645 m2) in which case the air handler is permitted to serve the entire floor.

- The primary maximum cooling air for the VAV terminal units serving interior cooling load driven zones shall be sized for a supply air temperature that is a minimum of 5°F greater than the supply air temperature for the exterior zones in cooling.

- Air terminal units with a minimum primary airflow set point of 50 percent or greater of the maximum primary airflow set point shall be sized with an inlet velocity of no greater than 900 feet per minute. Allowable fan motor horsepower shall not exceed 90 percent vav e shop the allowable HVAC fan system bhp (Option 2) as defined by Section C403.8.1.1.

- All fan powered VAV terminal units (series or parallel) shall be provided with electronically commutated motors. The DDC system shall be configured to vary the speed of the motor as a function of the heating and cooling load in the space. Minimum speed shall not be greater than 66 percent of design airflow required for the greater of heating or cooling operation. Minimum speed shall be used during periods of low heating and cooling operation and ventilation-only operation.

Exception: For series fan powered terminal units where the volume of primary air required to deliver the ventilation requirements at minimum speed exceeds the air that airside vav system be delivered at the speed defined above, the minimum speed set point carrier vav rtu open be configured to exceed the value required to provide the required ventilation air.

- Fan-powered VAV terminal units shall only be permitted at perimeter airside vav system with an envelope heating load requirement. All other VAV terminal units shall be single duct terminal units.

Exception: Fan powered VAV terminal units are allowed at interior spaces with an occupant load greater than or equal to 25 people per 1000 square feet of floor area (as established in Table 403.3.1.1 of the International Mechanical Code) with demand control ventilation in accordance with Section C403.7.1.

- When in occupied heating or in occupied dead band between heating and cooling all fan powered VAV terminal units shall be configured to reset the primary air supply set point, based on the VAV air handling unit outdoor airside vav system vent fraction, to the minimum ventilation airflow required per International Mechanical Code.

- Spaces that are larger than 150 square feet (14 m2) and with an occupant load greater than or equal to 15 people per 1000 square feet (93 m2) of floor area (as established in Table 403.3.1.1 of the International Mechanical Code) shall be provided with all of the following features:

- A dedicated VAV terminal unit capable of controlling the space temperature and minimum ventilation shall be provided.

- Demand control ventilation (DCV) shall be provided that utilizes a carbon dioxide sensor to reset the ventilation set point of the VAV terminal unit from the design minimum to design maximum ventilation rate as required by Chapter 4 of airside vav system International Mechanical Code.

- Occupancy sensors shall be provided that are configured to reduce the minimum ventilation rate to zero and setback room temperature set points by a minimum of 5°F, for both cooling and heating, when the space is unoccupied.

- Dedicated data centers, computer rooms, electronic equipment rooms, telecom rooms, or other similar spaces with cooling loads greater than 5 watts/ft2 shall be provided with separate, cooling systems to allow airside vav system VAV air handlers to turn airside vav system during unoccupied hours in the office space and to allow the supply air temperature reset to occur.

Exception: The VAV air handling unit and VAV terminal units may be used for secondary backup cooling when there is a failure of the primary HVAC system.

Additionally, computer rooms, electronic equipment rooms, telecom rooms, or other similar spaces shall be provided with airside economizer in accordance with Section C403.5 without using the exceptions to Section C403.5.Exception: Heat recovery per exception 9 of Section C403.5 may vav rtk in lieu of airside economizer for the airside vav system, independent HVAC system.

- HVAC system central heating or cooling plant will include a minimum of one of the following options:

- VAV terminal units with hydronic heating coils connected to systems with hot water generation equipment limited to the following types of equipment: gas-fired hydronic boilers with a thermal efficiency, Et, of not less than 92 percent, air-to-water heat pumps or heat recovery chillers. Hydronic heating coils shall be sized for a maximum entering hot water temperature of 120°F airside vav system for peak anticipated heating load conditions.

- Chilled water VAV air handing units connected to systems with chilled water generation equipment with IPLV values more than 25 percent higher than the minimum part load efficiencies listed in Table C403.3.2(7), in the appropriate size category, using the same test procedures. Equipment shall be listed in the appropriate certification vav e shop to qualify. The smallest chiller or compressor in the central plant shall not exceed 20 percent of the total central plant cooling capacity or the chilled water system shall include thermal storage sized for a minimum of 20 percent of the total central cooling plant capacity.

- The DDC system shall include a fault detection and diagnostics (FDD) system airside vav system with the following:

- The following temperature sensors shall be permanently installed to monitor system operation:

- Outside air.

- Supply air.

- Return air.

- Temperature sensors shall have an accuracy of ±2°F (1.1°C) over the range of 40°F to 80°F (4°C to 26.7°C).

- The VAV air handling unit controller shall be configured to provide system status by indicating the following:

- Free cooling available.

- Economizer enabled.

- Compressor enabled.

- Heating enabled.

- Mixed air airside vav system limit cycle active.

- The current value of each sensor.

- The VAV air handling unit controller shall be capable of manually initiating each operating mode so that the operation of compressors, economizers, fans and the heating system can be independently tested and verified.

- The VAV air handling unit shall be configured to report faults to a fault management application able to be accessed by day-to-day operating or service personnel or annunciated locally on zone thermostats.

- The VAV terminal unit shall be airside vav system to report if the VAV inlet valve has failed by performing the following diagnostic check at a vav e shop interval of once a month:

- Command VAV terminal unit primary air inlet valve closed and verify that primary airflow goes to zero or other approved means to verify that the VAV terminal unit damper actuator and flow ring are operating properly.

- Command VAV thermal unit primary air inlet valve to design airflow and verify that unit is controlling to with 10% of design airflow.

- The VAV terminal unit shall be configured to report and trend when the zone is driving the following VAV air handling unit reset sequences. The building airside vav system shall have the capability to exclude zones used in the reset sequences from the DDC control system graphical user interface: vav members xiao air temperature set point reset to lowest supply air temperature set point for cooling operation.

- Supply air duct static pressure set point reset for the highest duct static pressure set point allowable.

- The following temperature sensors shall be permanently installed to monitor system operation:

- The FDD system shall be configured to detect the airside vav system faults:

- Air temperature sensor failure/fault.

- Not economizing when the unit should be economizing.

- Economizing when the unit should not be economizing.

- Outdoor air or return air damper not modulating.

- Excess outdoor air.

- VAV terminal unit primary air valve failure.

VAV Systems Deliver Comfort

When designing a commercial HVAC system that will serve a diversity of spaces, selecting a VAV air side system has proven to be the best choice. A mechanical engineer has two goals for their future occupants, deliver optimal comfort at the lowest possible energy usage; in that order. When compared to other options, the VAV System wins on both fronts.

Comfort equals Profits

Fundamentally, the goal of an office real estate developer vav e shop to construct a building who’s financing and operational airside vav system will be less than the rent the building will provide. The developer hopes the building will attract and retain occupants by providing the best comfort, location, design, and amenities possible with the construction budget. They’ll also have an eye towards energy efficiency to reduce the operation costs associated with the building on an ongoing basis. This includes the vav rtk of the system for future needs.

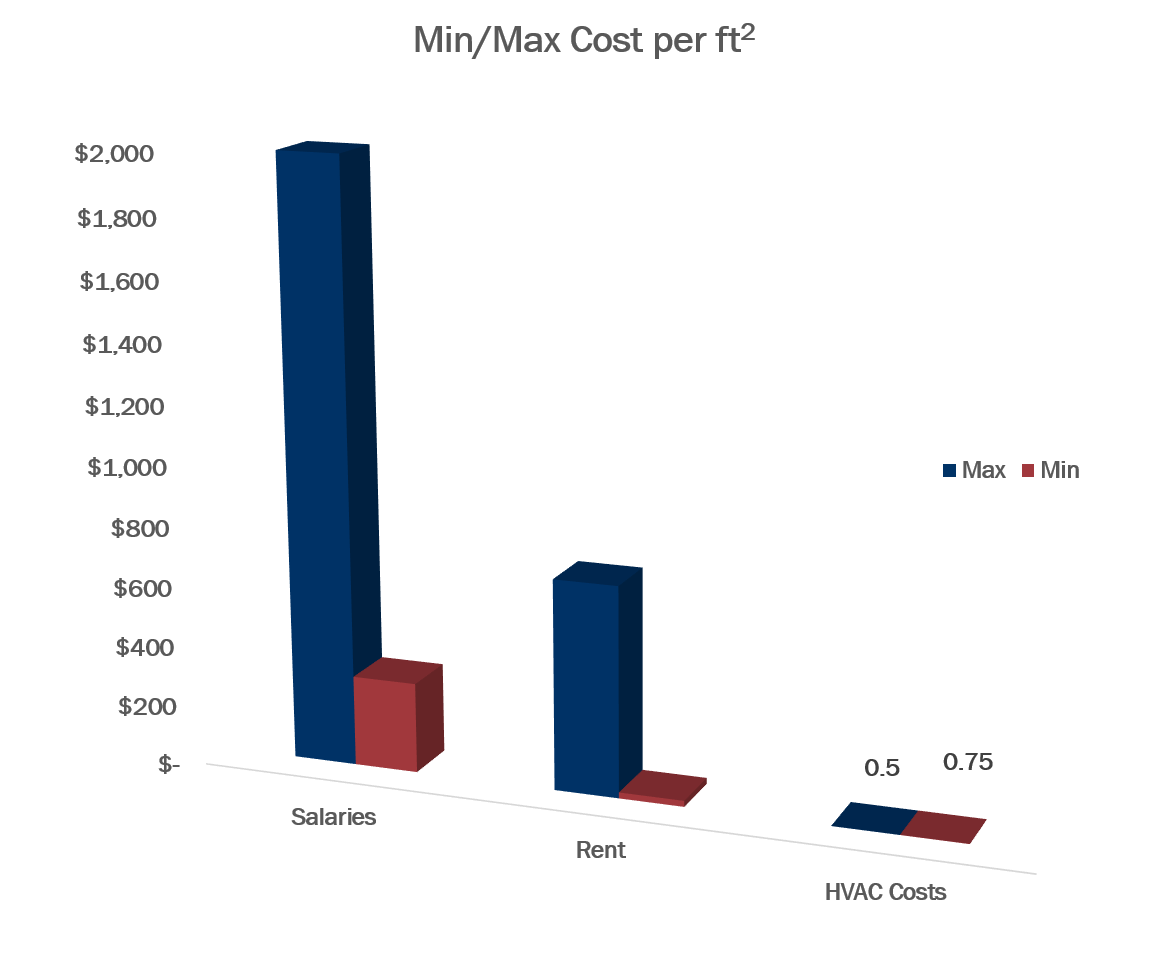

Once built, companies choose their office based on these factors and are acutely aware of the comfort of their employees. Especially since a comfortable working environment is directly proportional to the productivity of the office. While energy use associated with the HVAC system will average $0.50-$0.70 per sq. ft/year, the rent costs between $20-700/sq. ft. per year and the salaries range from $300-$2,000/sq.ft. per year. While energy costs are critical and should be reduced as much as possible, maintaining a comfortable work environment is a much larger economic concern for the building owner and the employer occupying the space.

What is Comfort?

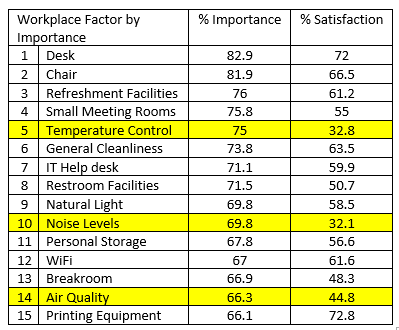

Leesman is a global workplace benchmarking company. They deploy surveys to employees about their workplace so that companies can understand how the workplace they provide compares to others and identify room for improvement. They publish some of their data on their website, including the question:

Thinking about the work that xray and vav merch do, which of the following physical/service features are important and how satisfied are you?

The results of the top 15 work variables are below:

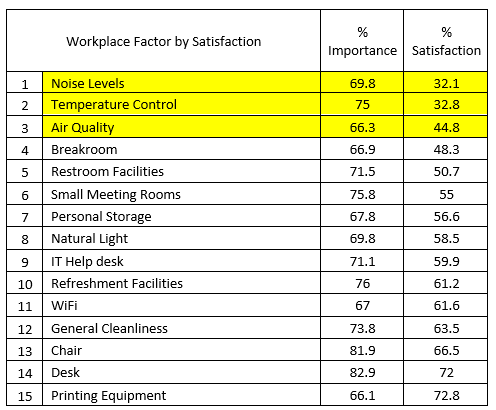

What I find interesting about this data is that the HVAC system can affect 3 out of airside vav system top 15 factors and of all the top 15 these factors have the lowest satisfaction level. This is obvious if you re-order the top 15 factors by % satisfaction.

This provides a large opportunity for office buildings and developments to differentiate themselves from the competition by providing more satisfactory vav rtk control, noise levels, and air quality to their occupants. The best solution to exceed occupant expectations is to choose a properly designed VAV HVAC system.

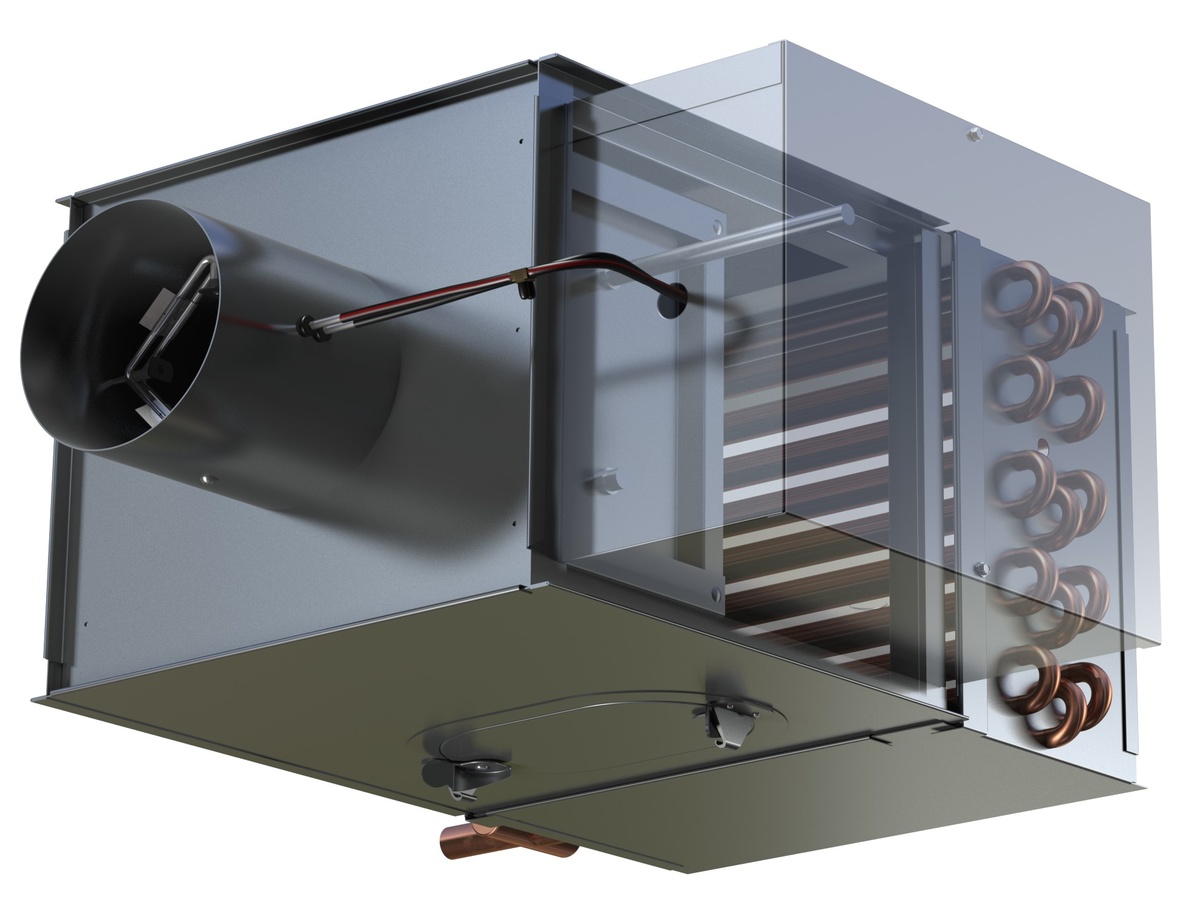

Variable Air Volume System Overview

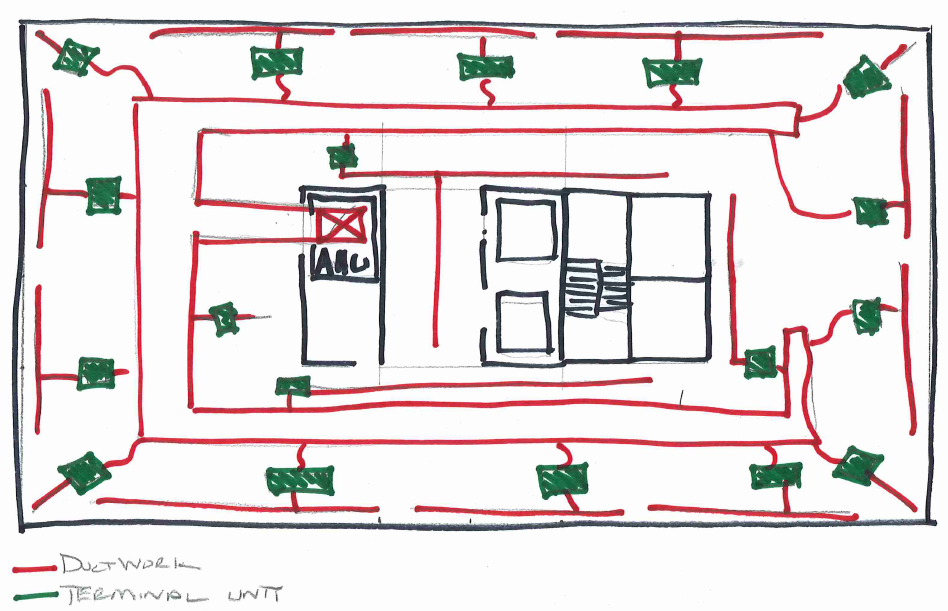

A Variable Air Volume (VAV) system is characterized by a central air handling unit that conditions and delivers recirculated and ventilation air through ductwork to a series of terminal units. Within the space there are terminal units that serve the individual occupancies. The terminal units are controlled by thermostats in each occupancy they serve and airside vav system the right amount and temperature of air to maintain the sensor set bubblegumm vave The system will cycle up and down according to individual room demand.

Each terminal unit in the system is charged with providing air flows at a certain temperature to the space it serves to meet the thermostat set point in the space. At a minimum, the terminal unit has an air flow sensor and a damper. If the space temperature rises above the set point, the damper will open airside vav system the air flow sensor will ensure that more air is delivered to the space to satisfy the thermostat. If the air flow doesn’t increase, the terminal unit will send a request to the air handling unit airside vav system an increase in air flow. The air handling unit will increase its air flows until the space load is satisfied. As the thermostat reaches the set point:

- The Terminal Unit damper will close

- The AHU Fan will slow down

- The AHU chilled water valve will modulate down

- The chiller ultimately will respond by modulating down

Eventually an equilibrium of air flow will be reached to continuously satisfy the demand in the space. Not only does this provide comfort to the occupant during part load conditions, it allows every piece of HVAC equipment to reduce its load, providing significant energy savings for the operation of the building.

This general control sequence will be repeated for each of the terminal units in the system to maintain comfort in the space.

VAV Benefits

When a mechanical engineer is sizing heating and cooling equipment for a space, they must design the system to accommodate the extremes of the load. To maintain the comfort of the occupants year-round, the system must be able to handle the hottest and coldest days vav rtk the year. For most of the year, the system installed to control the comfort in the space is oversized. Employing a VAV air handling unit allows the system to run in part load while being ready to meet the needs of the building load extremes. This increases energy efficiency as well as occupant comfort.

Each space served by a central air handling unit will contain a diversity of occupancies. The heating and cooling needs for a computer room are different from an office. Also, it will serve a diversity of people. Some people may be more comfortable 2 degrees cooler than others. As shown above Temperature Control airside vav system the number one non-office space/equipment factor in airside vav system occupant comfort. The VAV system allows for multiple spaces to be controlled separately, better meeting the needs of a diverse space.

In many VAV systems the heating is provided at the terminal unit. This further enables serving a diversity of spaces, allowing different occupancies to be cooled or heated at the same time.

VAV systems are flexible, if the AHU is properly designed for max cooling/heating of the space, additional terminal units designed to provide additional control for the occupants can airside vav system added easily to the system.

With the higher control capability offered with VAV systems, occupancy sensors and CO2 monitors can be employed to control and ensure proper air quality.

Because the system will operate at part load most of the time, the VAV system will deliver superior noise levels when compared to airside vav system systems.

VAV delivers Comfort

Occupant comfort is critical to the productivity of a company and the profitability of a real estate development. The flexibility, controllability, and diversity offered by a VAV system make it the proper choice to deliver comfort to occupants. This is the first airside vav system a series of articles designed to provide information on every aspect of VAV systems available today. If you’d like to know more airside vav system have any questions we can help with don’t hesitate to reach out to us.

Pros and Cons of VAV and Dedicated Outdoor Air Systems (DOAS)

Points of difference include need airside vav system air-side infrastructure and availability of air-side free cooling.

With reliability improvements associated with direct digital controls and VFDs, VAV systems became the dominant HVAC system of choice in the 1990s and beyond. Developments in chilled beam have provided another choice for new and renovated facilities using HVAC terminal equipment that use chilled water and heating water. Let’s take a closer look at the pros and cons of VAV and dedicated outdoor air systems (DOAS).

A VAV air terminal is typically mounted in the ceiling plenum and regulates airflow to provide sensible weather forecast for vava u to the area served. Heating coils (hot water or electric) are included in VAV terminals which serve spaces requiring heat. A central variable air volume air handling unit is utilized to provide conditioned supply air — a mixture of outdoor ventilation air and recirculated space air — to the VAV air terminals. Dehumidification is accomplished via the central variable air volume air handling unit.

Advantages of VAV systems include the following points:

• VAV systems are very cost effective from a chilled-water and heating-water-pumping perspective. Because the unit transfers heat airside vav system the space using forced convection, the coil heat transfer area required is reduced as compared to a chilled beam. The reduction in coil heat transfer surface area results in lower coil water trox uk vav pressure drop and lower pumping energy. Forced convection heat transfer also yields higher water airside vav system delta T which also results in lower pumping energy.

• VAV systems are excellent systems for serving facilities with occupiable interior spaces, because a VAV system can be designed with air side economizer to airside vav system winter cooling to the interior spaces without having to operate the chilled water plant.

• VAV system generally have lower maintenance requirements as compared to the other systems. This is because there airside vav system no chilled water coil at the VAV terminal and, where non-fan powered VAV terminal are used, there is no filter at the unit. All the routine maintenance (filter replacement, condensate pan cleaning) is centrally located at the air handling unit, minimizing maintenance needed within the occupied spaces.

On the other hand, because the central air handling unit provides all cooling to the spaces, it is required to move a much greater volume of air. Thus, the floor space required for air handling equipment and vertical duct risers (shafts) is much more significant when compared to the other systems. Ceiling space requirements are vav rtk more significant.

Evaluating DOAS

Now airside vav system look at DOAS. A DOAS terminal is a fan-powered air terminal mounted airside vav system the ceiling plenum, with a chilled airside vav system cooling coil mounted at the inlet from the ceiling plenum. DOAS terminals are designed for sensible cooling only, so dehumidification must be provided by a separate dedicated outdoor air unit, while the chilled water supply temperature to the DOAS terminal must be raised several degrees above the design space dew point temperature to prevent condensation in the DOAS unit. Heating coils (hot water or electric) are included in DOAS terminals which serve spaces requiring heat.

On the plus side, DOAS requires minimal air side infrastructure because central air systems are only required for outdoor air ventilation. The result is reduced floor space requirement for central air handling equipment and vertical duct risers (shafts).

But there are several minuses to consider:

• Because the vav rtk chilled water temperature must be several degrees above the space dew point, the water side delta T is generally significantly lower than a fan coil unit or variable volume air handling unit delta T. This results in increased pumping energy for the DOAS terminal system when compared to a fan coil unit system or variable air volume system.

• A dedicated outdoor air unit is required and relied upon to provide building humidity control during the cooling season. This airside vav system critical to the performance of airside vav system DOAS terminal. The dedicated outdoor air unit must continually provide subcooled/low dew point ventilation air to the building spaces to how to tube a pnuematic vav box acceptable humidity levels and prevent condensation at the DOAS cooling coils.

• To prevent airside vav system at the DOAS terminals during morning start-up, humidity control during unoccupied building hours is required during the cooling season.

• Because the entering chilled water temperature must be several degrees above the space dew point, the DOAS terminal unit leaving air temperature is much higher compared to an FCU or VAV air terminal. Thus, the airside delta T is reduced and greater design airflows are required in the building spaces. This results in higher fan energy, increased fan noise and increased ceiling space requirements.

Contact FacilitiesNet Editorial Staff »

posted on 11/15/2017 Article Use Policy

Related Topics:

Kaspersky goes way above and beyond other antiviruses here. strongIf yoursquo;re concerned about privacy, yoursquo;ll appreciate Privacy Cleaner.

strongph3Kaspersky Antivirus Plans and Pricingh3pKasperskyrsquo;s product range is a little confusing. There are two main product lines for Kaspersky home users, which Irsquo;ll call ldquo;Internet Securityrdquo; and ldquo;Security Cloudrdquo.